2

Workshop Manual, TSD3450E, Issue 1 25

2800

Torque figures for standard hose clamps of the worm drive band type

Torque figures for constant torque hose clamps

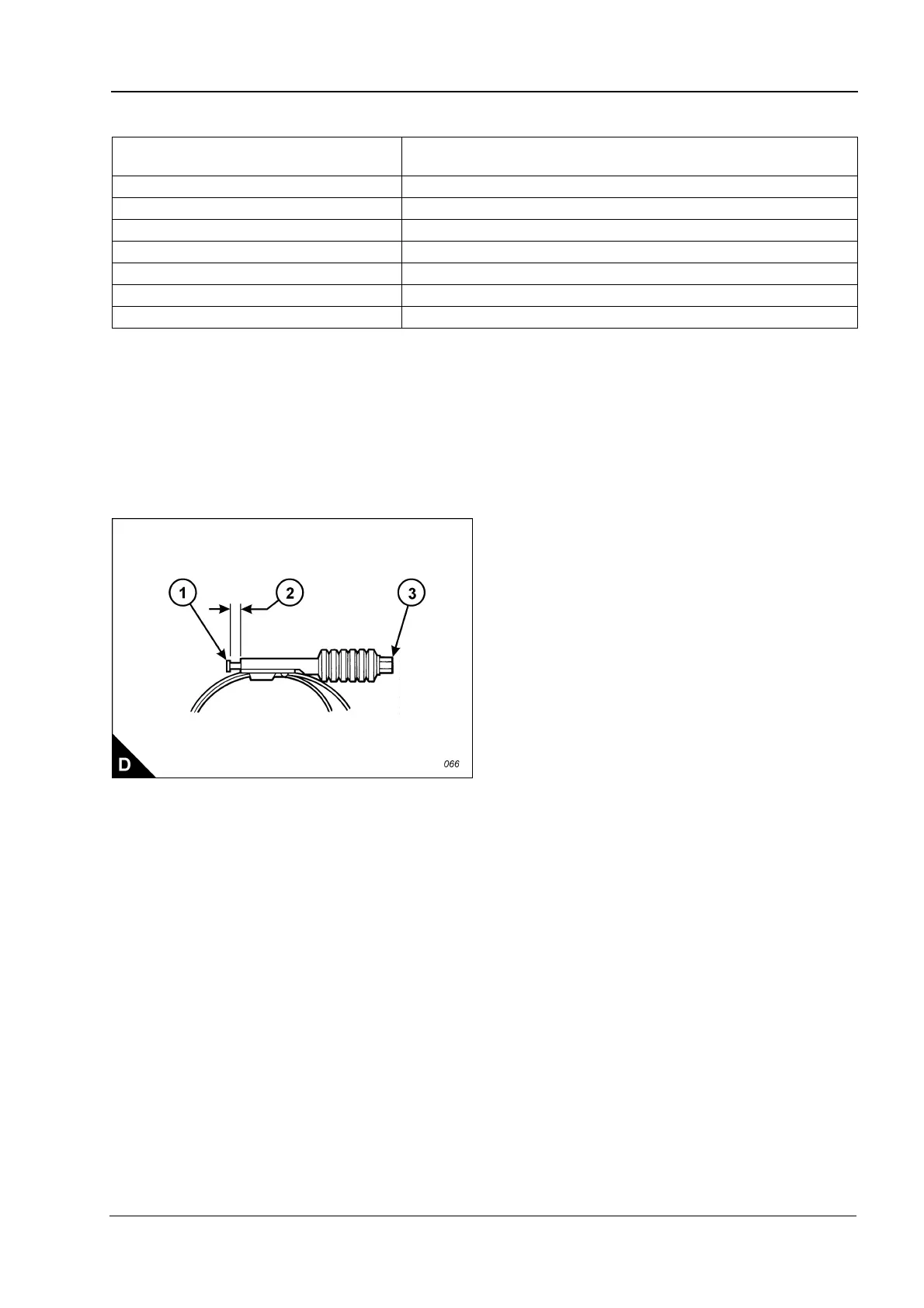

Use a torque wrench for the correct installation of a constant torque hose clamp. For a constant torque hose

clamp to be installed correctly, these conditions must exist:

The screw tip (D1) must extend by 6,35 mm (0.250 in) beyond the housing (D2).

The belleville washers must be collapsed almost flat after the screw (D3) has been tightened to a torque of

11 +/- 1 Nm (98 +/- 9 lb in).

Width of clamp

Torque figure for initial

installation on a new hose

7,9 mm (0.31 in) 0,9 +/- 0,2 Nm (8 +/- 2 lbf in)

13,5 mm (0.53 in) 4,5 +/- 0,5 Nm (40 +/- 4 lbf in)

15,9 mm (0.63 in) 7,5 +/- 0,5 Nm (65 +/- 4 lbf in)

Width of clamp Torque figure for used clamp

7,9 mm (0.31 in) 0,7 +/- 0,2 Nm (6 +/- 2 lbf in)

13,5 mm (0.53 in) 3,0 +/- 0,5 Nm (27 +/- 4 lbf in)

15,9 mm (0.63 in) 4,5 +/- 0,5 Nm (40 +/- 4 lbf in)

Loading...

Loading...