3

Workshop Manual, TSD3450E, Issue 1 37

2800

To fit

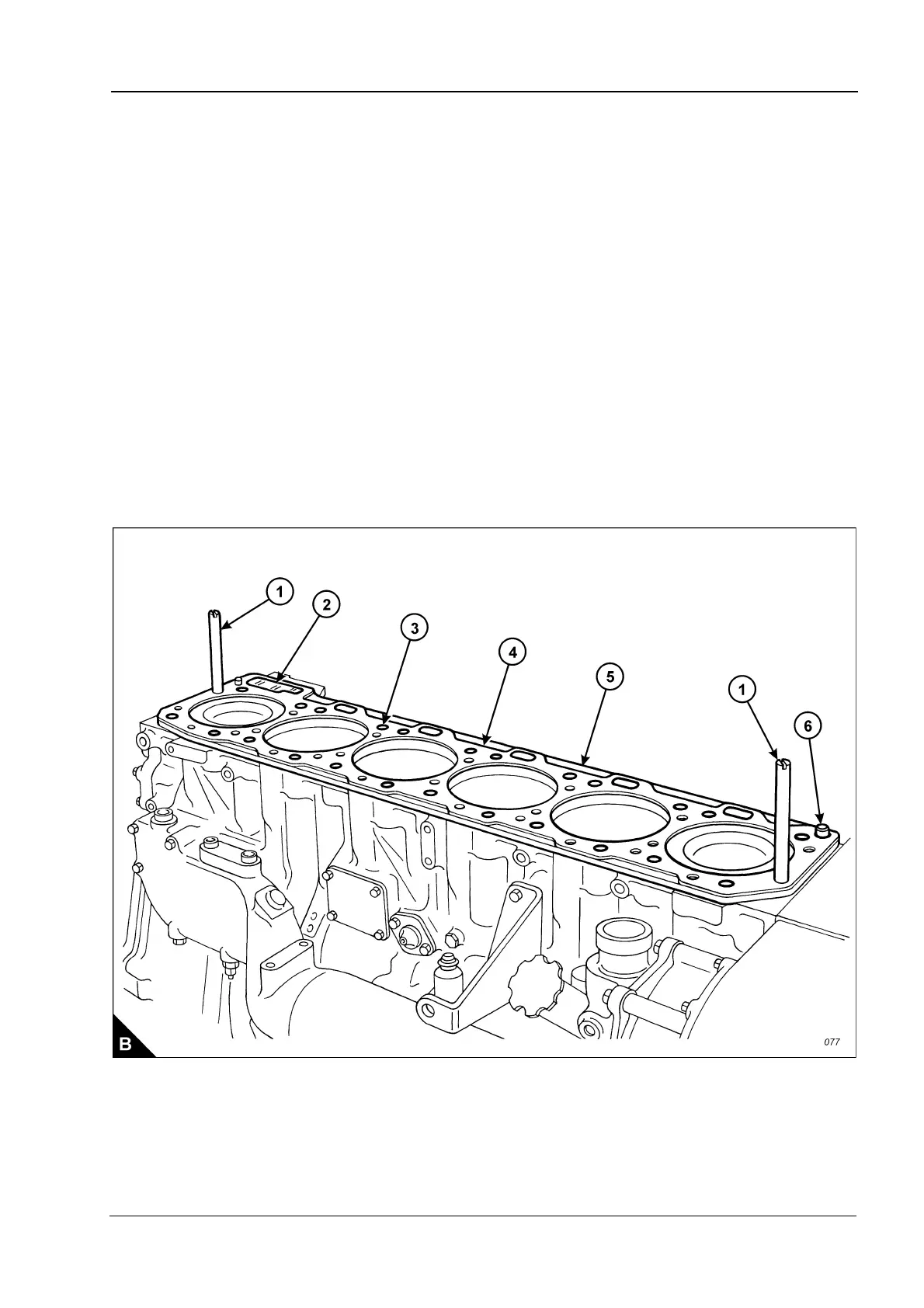

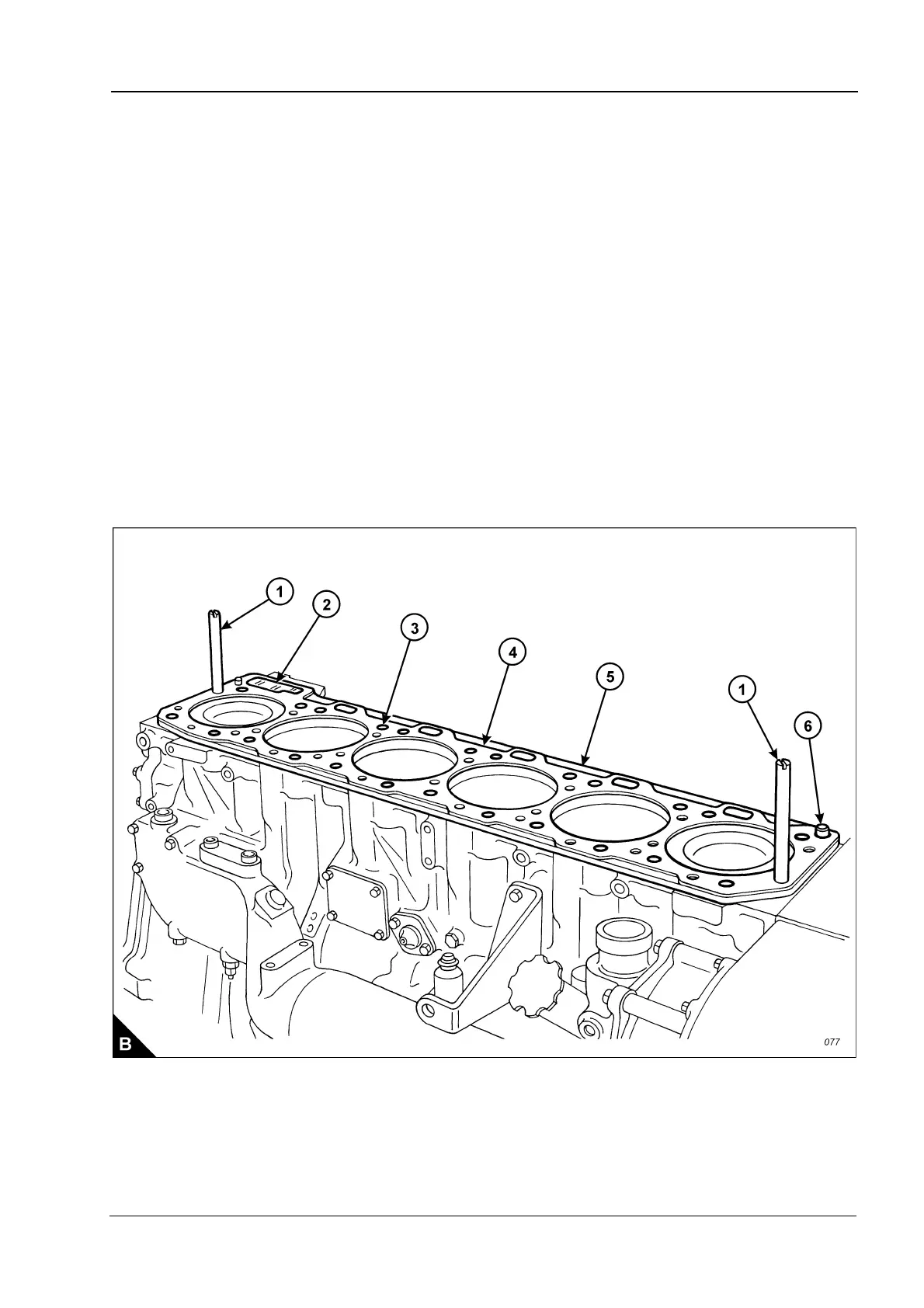

1 If the oil transfer tube (B6) has been removed, apply retaining compound, 21820 638, and insert it in the

crankcase. It must protrude from the top face of the crankcase by 20,0 +/- 0,5 mm (0.79 +/- 0.02 in). Remove

any excess compound and ensure that the bore of the oil transfer tube is clean.

2 If the rear dowel has been removed, apply retaining compound, 21820 638, and insert it in the crankcase.

It must protrude from the top face of the crankcase by 18,5 +/- 0,5 mm (0.73 +/- 0.02 in).

3 If the front dowel, close to the oil transfer tube, has been removed, it must be fitted in a dry condition. It must

protrude from the top face of the crankcase by 16,0 +/- 0,5 mm (0.63 +/- 0.02 in).

Note: Ensure that the spacer plate and the machined surface of the cylinder block are clean and free from dirt

and gasket material. Both surfaces of the spacer plate gasket and the top of the cylinder block must be clean.

Do NOT use a gasket adhesive on the surfaces.

4 Fit suitable guide studs (B1) to the cylinder block. Fit a new spacer plate gasket over the dowels in the

cylinder block.

Note: Apply a small amount of clean engine oil to the seals and ‘O’ ring seals before installation.

5 Fit a new ‘O’ ring seal to the oil transfer tube (B6).

6 Fit the spacer plate (B5) and fit the second ‘O’ ring seal to the oil transfer tube (B6). Fit the 24 coolant seals

(B3) and a new seal (B2) to the oil drain passage.

7 Check, and if necessary adjust, the protrusion of the cylinder liners, Operation 7-3.

8 Fit a new cylinder head gasket (B4) to the spacer plate.

Continued

Loading...

Loading...