PG DRIVES TECHNOLOGY I-DRIVE TECHNICAL MANUAL – INSTALLATION

4 Tiller Interface

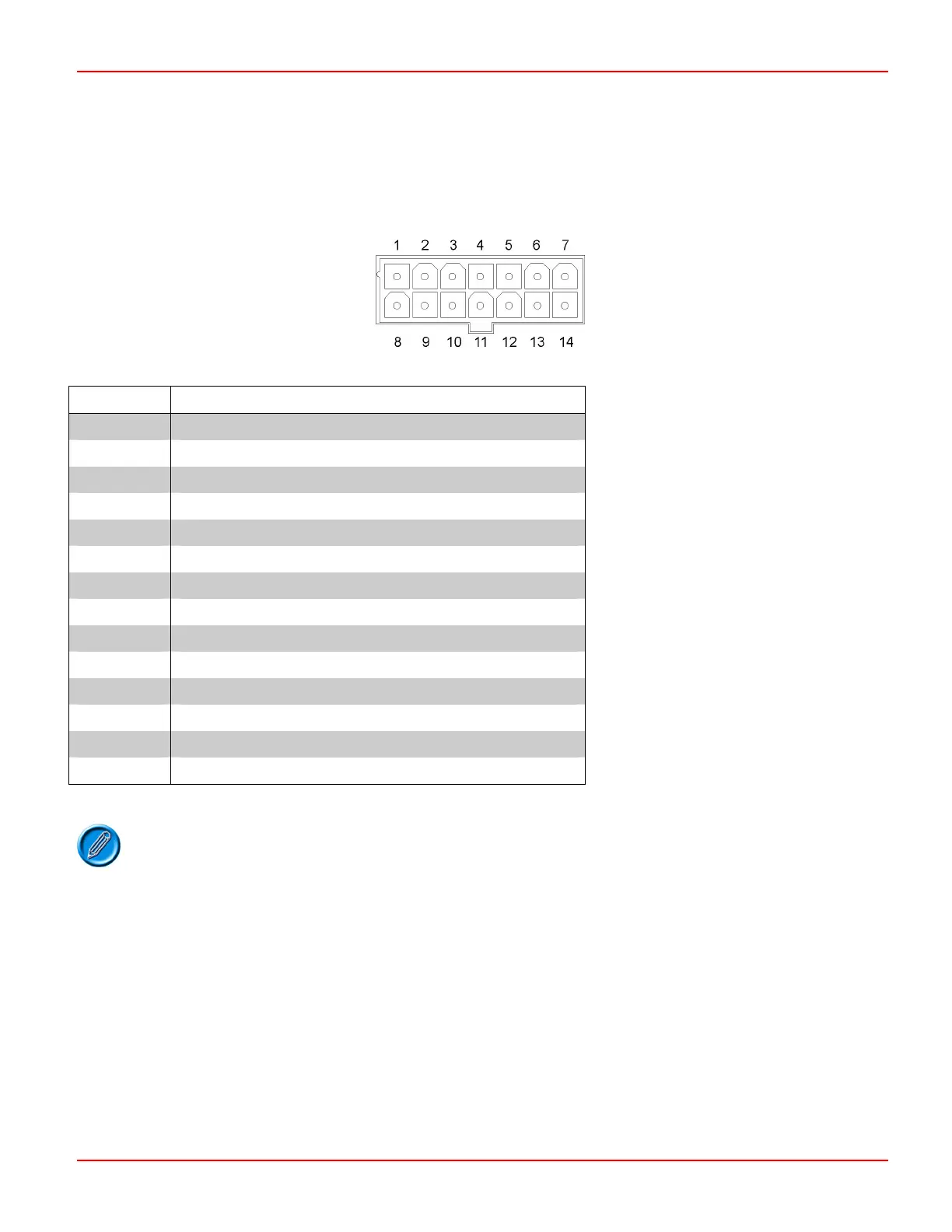

The Tiller Interface connections are via a 14 way Molex ‘Mini-Fit-Jr.’ connector. PGDT can supply these parts or Molex can be

contacted directly. Refer to Section

3.2.3 for part numbers and connector details.

Pin Number Description

1 Throttle Wiper

2 Throttle High Reference

3 Auxiliary 2 Output

4 Slow/Fast Switch

5 On/Off Switch

6 Inhibit 1 / Forward Direction Switch*

7 Fused B+ Supply

8 Throttle Low Reference

9 Speed Limiting Potentiometer Wiper / Belly Button Input

10 Status Indicator

11 Auxiliary 3 Output

12 Reverse Switch / Auxiliary 3 Input / Reverse Direction Switch*

13 0V

14 Inhibit 2 / Tiller Switch*

*This functionality is standard on i140 and i180 only. Please contact PGDT if this functionality is

required on your i45 or i70 application.

The i-Drive family provides a versatile method of machine control. To maximize this versatility, the tiller interface can be wired in

many different ways to suit a range of machine functionality. Each method of connection is individually described in this section.

4.1 Throttle Potentiometer Configuration

Pins 1, 2 and 8 are the connections to the throttle potentiometer. Wig-wag, single-ended and unipolar throttle configurations can

be used but you should ensure the controller is programmed to the correct type.

Refer to Chapter 3.

The value of the potentiometer should be 5kΩ ± 20%. If the full electrical span of the potentiometer is not used, Throttle Gain

can be programmed such that full speed can be achieved.

Refer to Chapter 3.

If the machine has a wig-wag throttle configuration it is possible, by programming, to reverse the polarity of operation of the

throttle. For single-ended throttles the polarity of operation of the reverse switch can be selected.

Refer to Chapter 3.

SK76977-07 35

Loading...

Loading...