What to do if Philips M3015A say 'BATTERY LOW'?

- JJames EdwardsAug 18, 2025

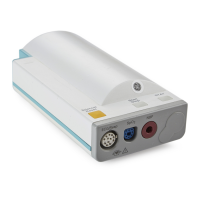

If your Philips Measuring Instruments display a 'BATTERY LOW' message, it means the battery has less than 20 minutes of charge remaining. The suggested solution is to recharge the battery.