Preventive Maintenance Tests

148

Testin

the Instrument

NBP Linearity Test

Step 1 Reduce the manometer pressure to 150 mmHg.

Step 2 Wait 10 seconds for the measurement to stabilize.

Step 3 After these 10 seconds, compare the manometer value with the displayed value.

Step 4 Document the value displayed by the M3046A (x3)

Step 5 If the difference is greater than 3 mmHg, calibrate the Server (see steps 10 to 12 in

the Accuracy Test procedure).

Valve Test

Step 1 Raise the pressure again to 280 mmHg.

Step 2 Select “Close valves: Off”.

Step 3 Wait 5 seconds then document the value displayed. The value should be less than 10

mmHg.

Step 4 Document the value displayed by the M3046A (x4).

Sidestream CO

2

Performance Test

NOTE 1. Allow 5 seconds between individual service procedures in order to ensure stable

equipment conditions.

2. When certain Monitor procedures are running (for example, AutoZero or purging), service

procedures are not possible and trying to start them will result in a message “Service

Operation Failed” in the status line on the Monitor. Wait until the Monitor has completed the

current operation, then restart the service procedure.

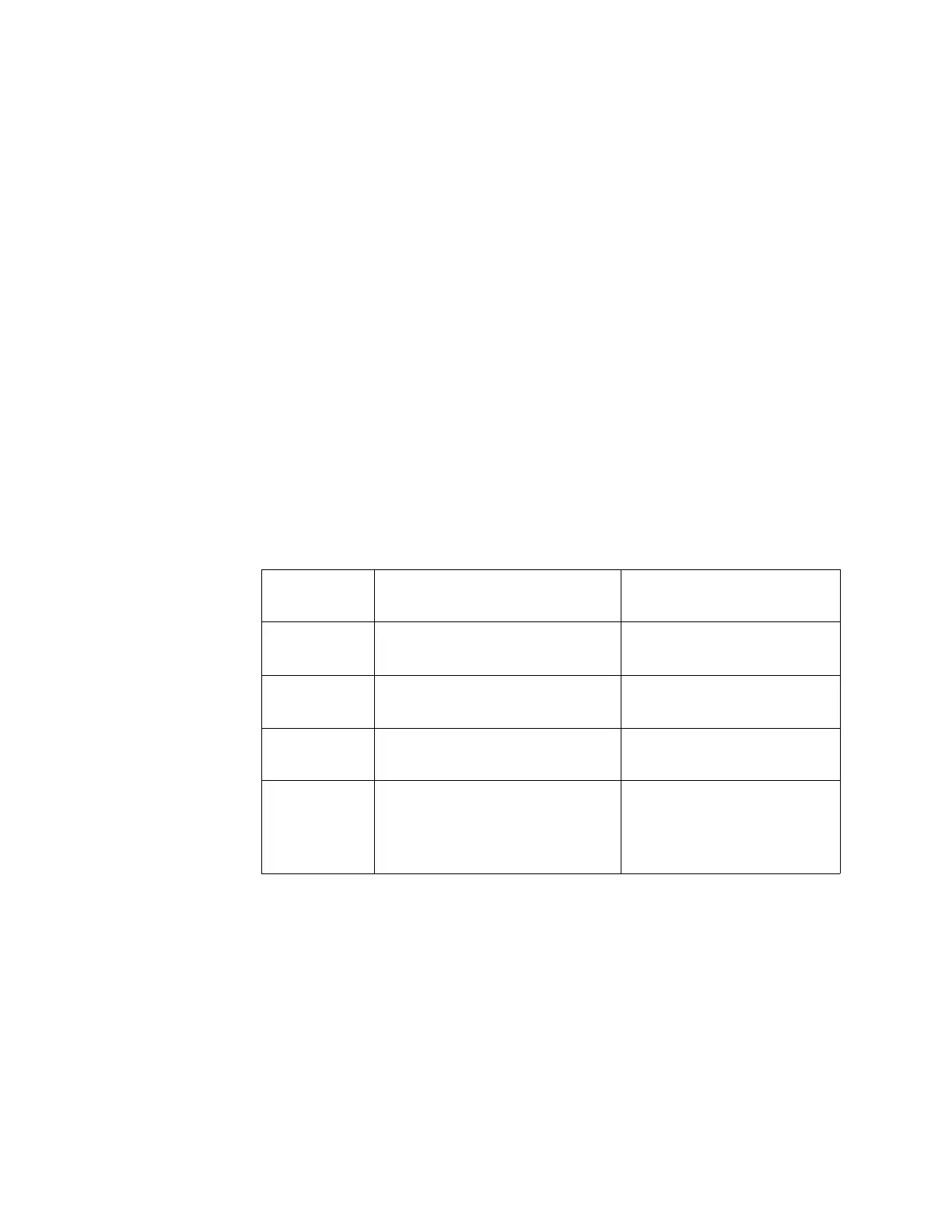

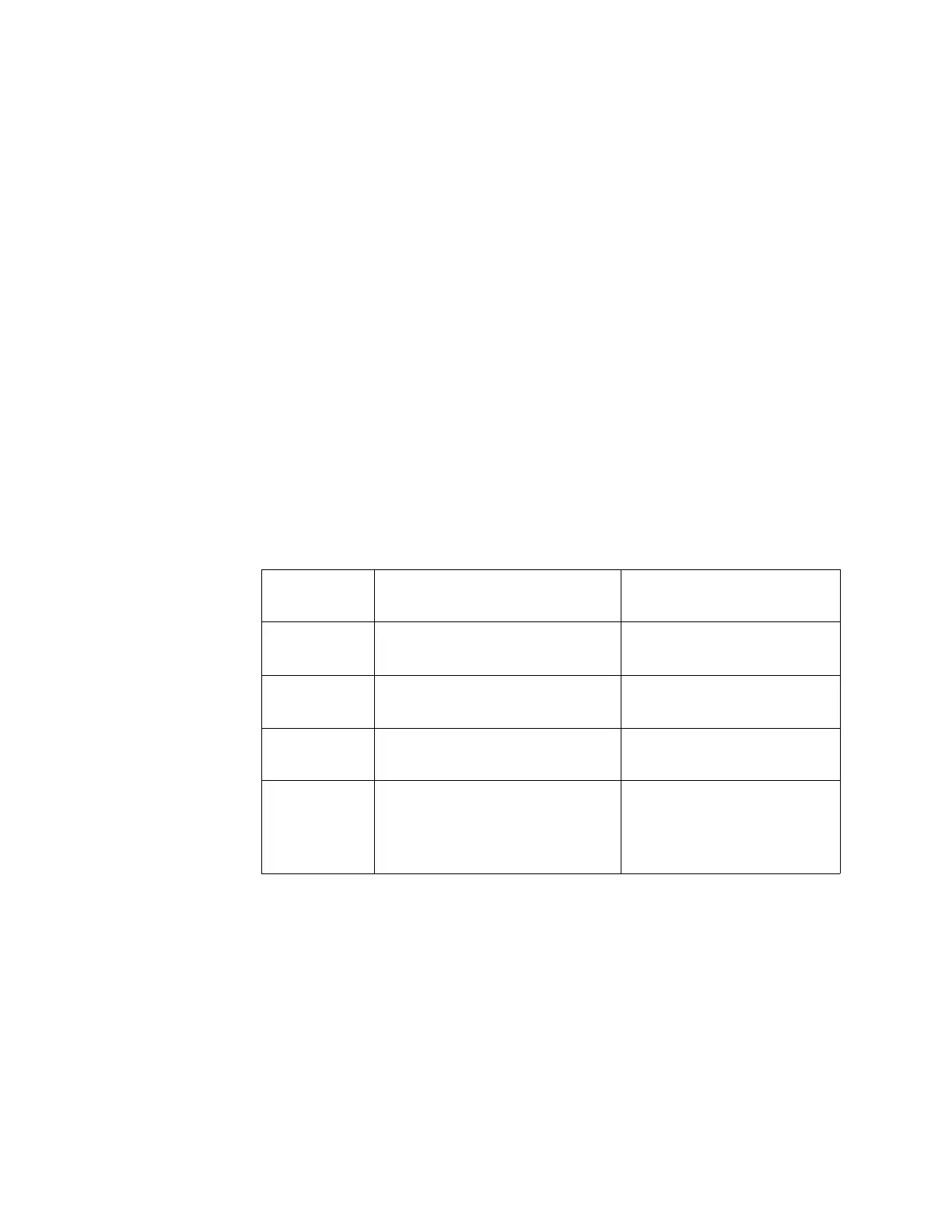

Test Expected test results What to record on the

Service record

Accuracy test x1 = value displayed by M3046A

Difference ≤ 3mmHg

Leakage test x2 = leakage test value

x2 < 6 mmHg

Linearity test x3 = value displayed by M3046A

Difference ≤ 3mmHg

Valve Test x4 = value < 10 mmHg PN:P/x1/x2/x3/x4

or

PN:F/x1/x2/x3/x4

where P = Pass and F = Fail

Loading...

Loading...