Preventive Maintenance Tests

Testin

the Instrument

151

Step 10 Block the inlet of the FilterLine using your fingertip and observe the flowmeter

display. The value on the flowmeter (x3) should decrease to between 0 and 4 ml/

min, accompanied by an audible increase in pump noise. (Do not block the inlet for

longer than 25 seconds as this will lead to an “Occlusion” INOP.) If the value is

within the tolerance limits, there are no leakages and the leakage check is

completed; proceed to the Pump Check.

Step 11 If the value is not within the tolerance limits, there is a leakage between the

FilterLine inlet and the pump inlet.

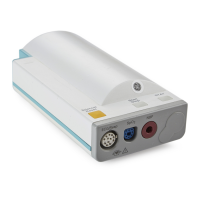

Step 12 Check the FilterLine connections and open the M3015A to check the tubing

connections at the pump inlet and the M3015A gas inlet. If the connections are

good, try replacing the FilterLine and repeating the leakage check. If the situation

remains, there is a leakage in the tubing and the M3015A must be exchanged.

Pump Check

Step 1 Connect the flowmeter inlet to the M3015A gas outlet.

Step 2 Connect the FilterLine to the M3015A inlet.

Step 3 Block the inlet of the FilterLine using your fingertip and observe the cell pressure

on the M3046A display. The cell pressure (x4) should be more than 120 mmHg

below the ambient pressure shown. If the pressure difference is less than 120

mmHg, the pump is not strong enough and should be replaced (irrespective of the

Pump OpTime).

Flow Rate Check and Calibration

Check the flow rate in the sidestream CO

2

Extension as follows:

Step 1 Connect the flowmeter to the CO

2

FilterLine.

Step 2 Check on the flowmeter the flow that the sidestream CO

2

Extension Pump draws

(x5). It should be 50 ml/min ± 7.5 ml/min. If the value is within tolerance, proceed

to the CO

2

Gas calibration check. If the value is not within tolerance, calibrate as

follows.

Step 3 Adjust the flow in the Instrument by selecting “Increase Flow” or “Decrease Flow”

until it is as close as possible to 50 ml per minute as indicated on the flowmeter

gauge.

Step 4 When you are satisfied that the flow is set as close as possible to 50 ml per minute,

select “Store Flow” and confirm the setting.

NOTE If the adjusted flow is not stored within 60 seconds of the adjustment, the old flow setting

will be restored

If the flow cannot be adjusted to within tolerance, the pump should be replaced. If the flow

adjustment still cannot be made, this indicates a fault in the M3015A Measurement

Extension, which must be replaced.

Loading...

Loading...