118

Gas

Edition 10-2008a

Check Gas Type / Gas Conversion

Whenever

changing connected type of gas a detailed ue gas analysis

MUST be done using

adequate CO and CO

2

measuring equipment!

This shall ONLY be done by trained technicians!

Changing the gas setting only by adjusting the CO

2

screw will result in an unsafe ue gas

condition, is dangerous to life and will damage the equipment

!

Note: Yearly maintenance of Gas components is needed:

Clean Burner head, Electrode and interior blower housing from fats and dust! (TI03-2007)

1) Select any mode and cooking time

2) Open control panel

3) Set DIP switch 1 on PCB to „ON“ position

4) With timer dial select: „SE“ = Settings:

5) Activate „Settings“ by pressing core temperature key; display changes to „SE1“

6) With timer dial select: SE6

7) Activate position SE6 with timer key (keep key pressed)

8) Select new gas type with timer dial:

G20=Nat Gas H, G25=Nat Gas L, G30=3BP, G31=3P, 13A=Nat. Gas Japan

9) Con rm new gas type with core temperature key (now timer key can be released)

10) With timer dial select: SE7

11) Activate position SE7 with timer key (keep key pressed)

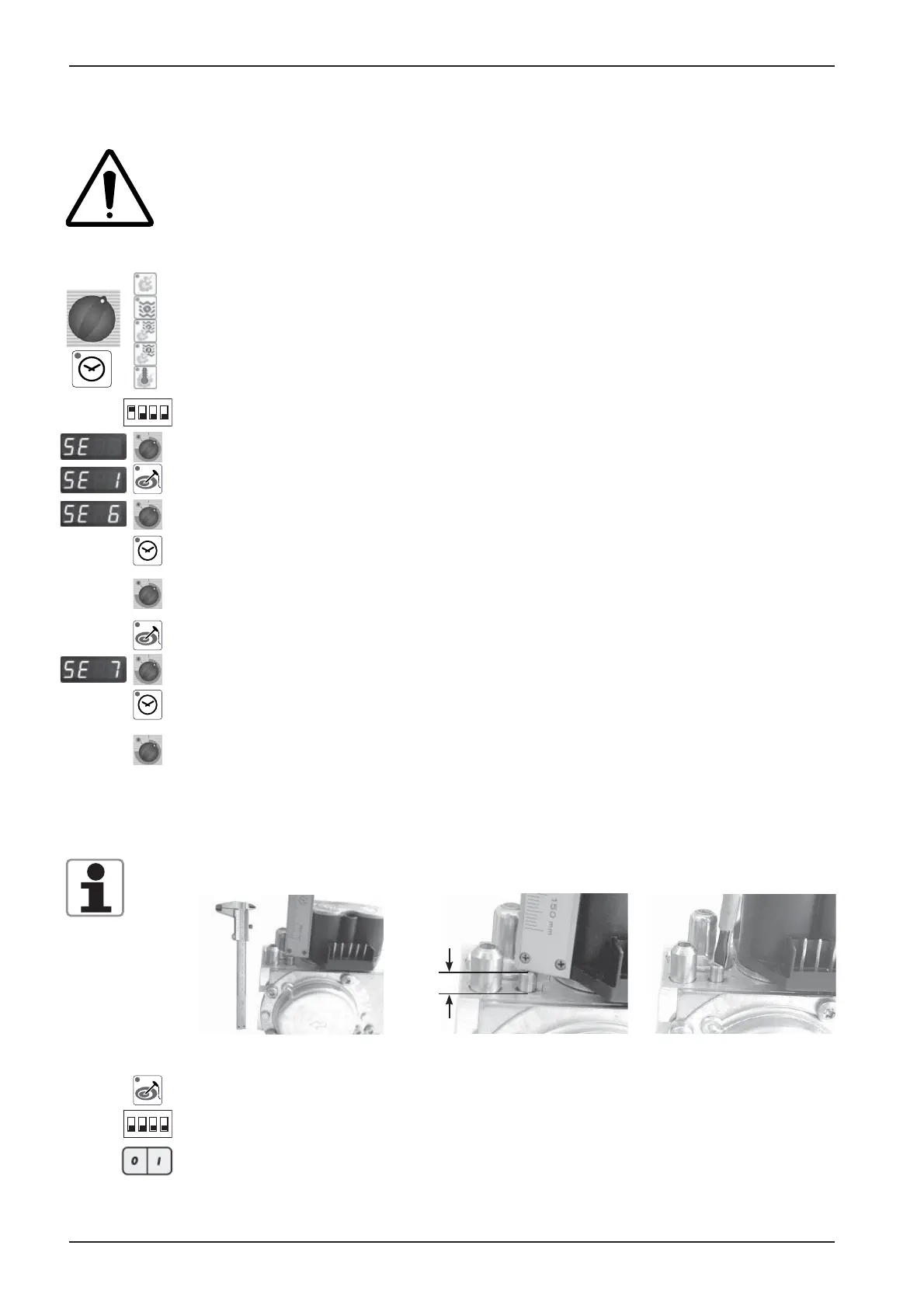

12) Keeping the timer key pressed the average length of the CO

2

screw is indicated. „St“

Steam, „HA1“ Hot air top, HA2“ Hot air bottom. Select the corresponding value with the

timer dial (keep timer key pressed)

13) Set the CO

2

screw according the values of timer display or according

the table “Values for burner adjustments“ Setting this screw to the given length shall

ONLY bring the unit into working condition with the newly supplied gas. (! ! ! Set all CO

2

screws ! ! !). If the mm setting of CO

2

screw is too high, turn CO

2

screw rst 1 turns

clockwise and then to the requested length (Screw adjustment tolerance).

This does NOT replace ue gas analysis or make the ue gas analysis obsolete!

14) De-activate selected package “SE“ by pressing core temperature key

15) To exit service program set DIP switch 1 to „OFF“ position

16) To store the new gas type the unit must be switched OFF and ON again

!

17) Check / Set Installation Altitude in Basic settings. Perform ue gas analysis in

function test at F21, F24, F27 as well as the check of CO

2

values at F19, F22, F25.

1

2

3

4

on

1

2

3

4

on

xx mm

Loading...

Loading...