133

Gas

Edition 10-2008a

Flue gas analysis for Hot Air at MAX rpm and cross checking CO

2

at MIN rpm

(201-202 only)

1) Switch on unit

2) Open front panel

3) Set DIP switch 1 on PCB to „ON“ position

4) Press Service-key

5) Select Function Test“

6) Select at „FunctionTest“ the position 16 „Gas Hot Air Burner BOTTOM“

7) Press key and select „Max“ rpm, if it‘s not already selected

8) Activate the burner with the „Start“ key.

Note: Start key is used as a switch and will automatically deactivate

after 4 minutes.

Display 4 indicates the desired CO

2

value, e.g. 9,2%, ame cur

rent, i.e. 5,5 A and the corresponding rpm of the blower motor.

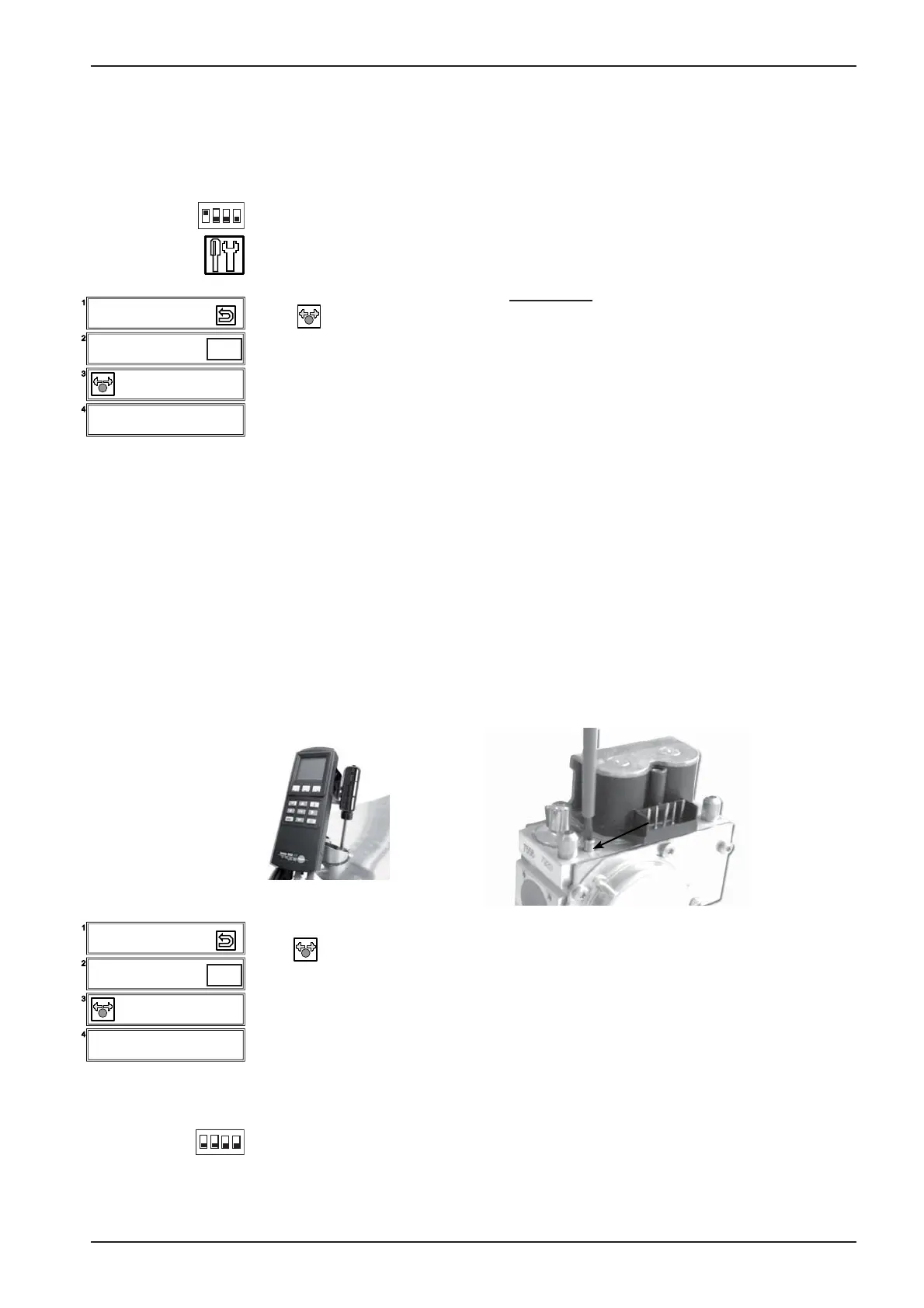

9) Place ue gas testing nozzle in correct ue outlet;

10) Adjust CO

2

to given value by turning CO

2

screw on gas valve.

You also can nd that value on table „Values for burner adjustments“

If CO

2

value is too low => turn CO

2

screw anti clockwise (+ direction),

If CO

2

value is too high => turn CO

2

screw rst 1 turns clockwise (- direc-

tion), and than slowly anti clockwise (+ direction) until you get the indicated

CO

2

value. (Screw adjustment tolerance).

CO value must be below 300 ppm!

11) Press „Stop“ key. Blower will stop.

12) Press key and select „Min“ speed.

13) Activate the burner with the „Start“ key. Note: Start key is used as a

switch and will automatically deactivate after 4 minutes

Check CO

2

values. Measured values shall correspond with the table

„Values for burner adjustment“ in this manual. Should CO2 value be out

of the allowable range change gas valve.

Press „Stop“ key. Blower will stop.

14) To exit program set DIP switch 1 to „OFF“;

1

2

3

4

on

16 - Function Test

Gas Hot Air Blower bottim

Max

CO2 FC rpm

xxx% 5,5A xxx

16 - Function Test

Gas Hot Air Blower Bottom

Min

CO2 FC rpm

xxx% 5,5A xxx

1

2

3

4

on

Start

Start

Loading...

Loading...