Vacuum spray degassing — 24.04.2020 - Rev. A

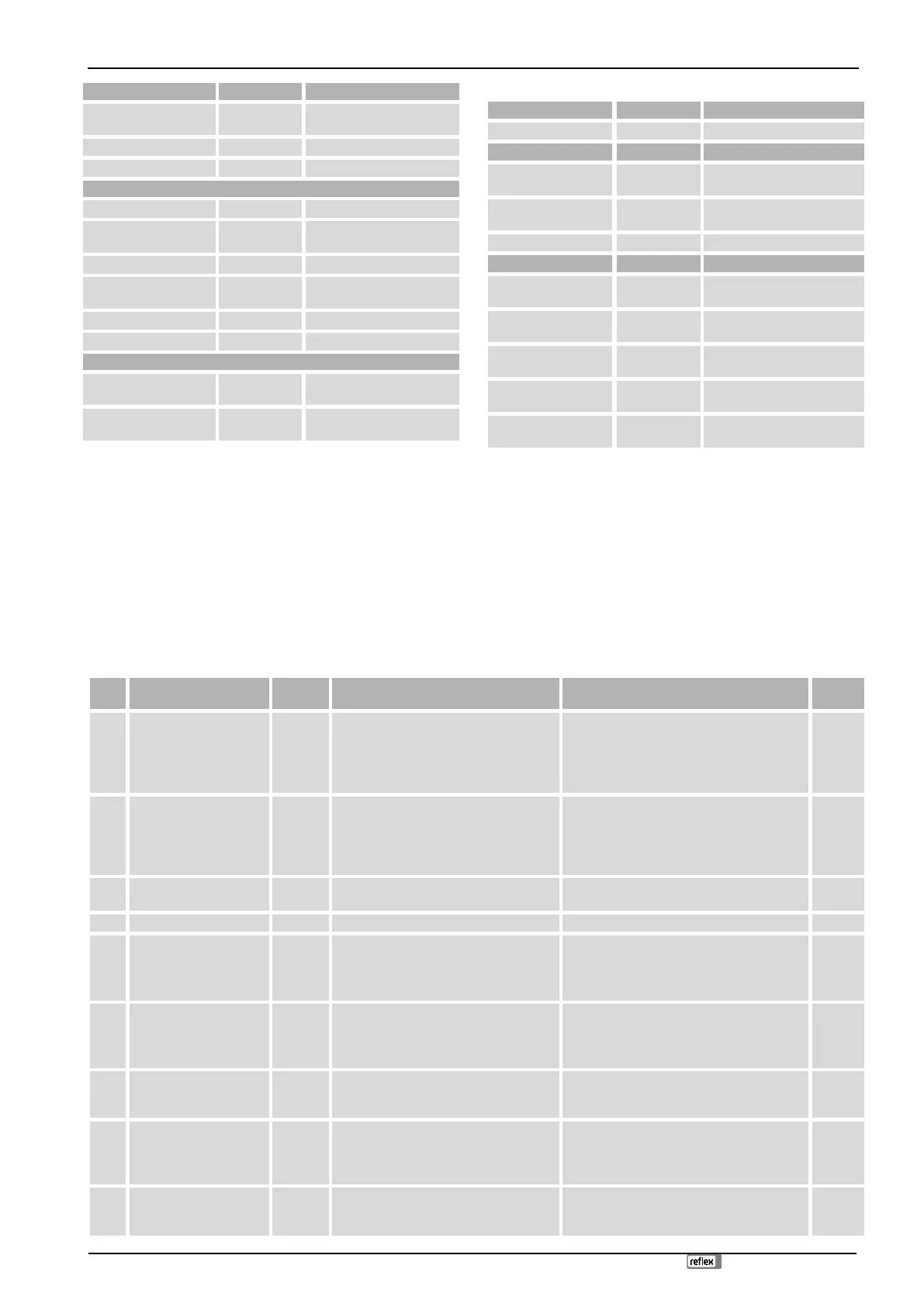

Attainable make-up quantity

Attainable water capacity

Desalination (only if "Water treatment" with "Desalination")

In the case of soft water

residual capacity = 0

Attainable make-up quantity

Attainable water capacity

Time left to the next due

maintenance

Only the messages marked in

the "Messages" list

Pressure differential,

"NSP" make-up

Pressure differential,

filling pressure PF – P0

Idling times between

degassing intervals

Idling times between the

degassing intervals

Number of degassing

cycles for each interval

Number of degassing cycles in

one interval

Start of the daily degassing

intervals

Time left to the next due

maintenance

Only the messages marked in the

message list

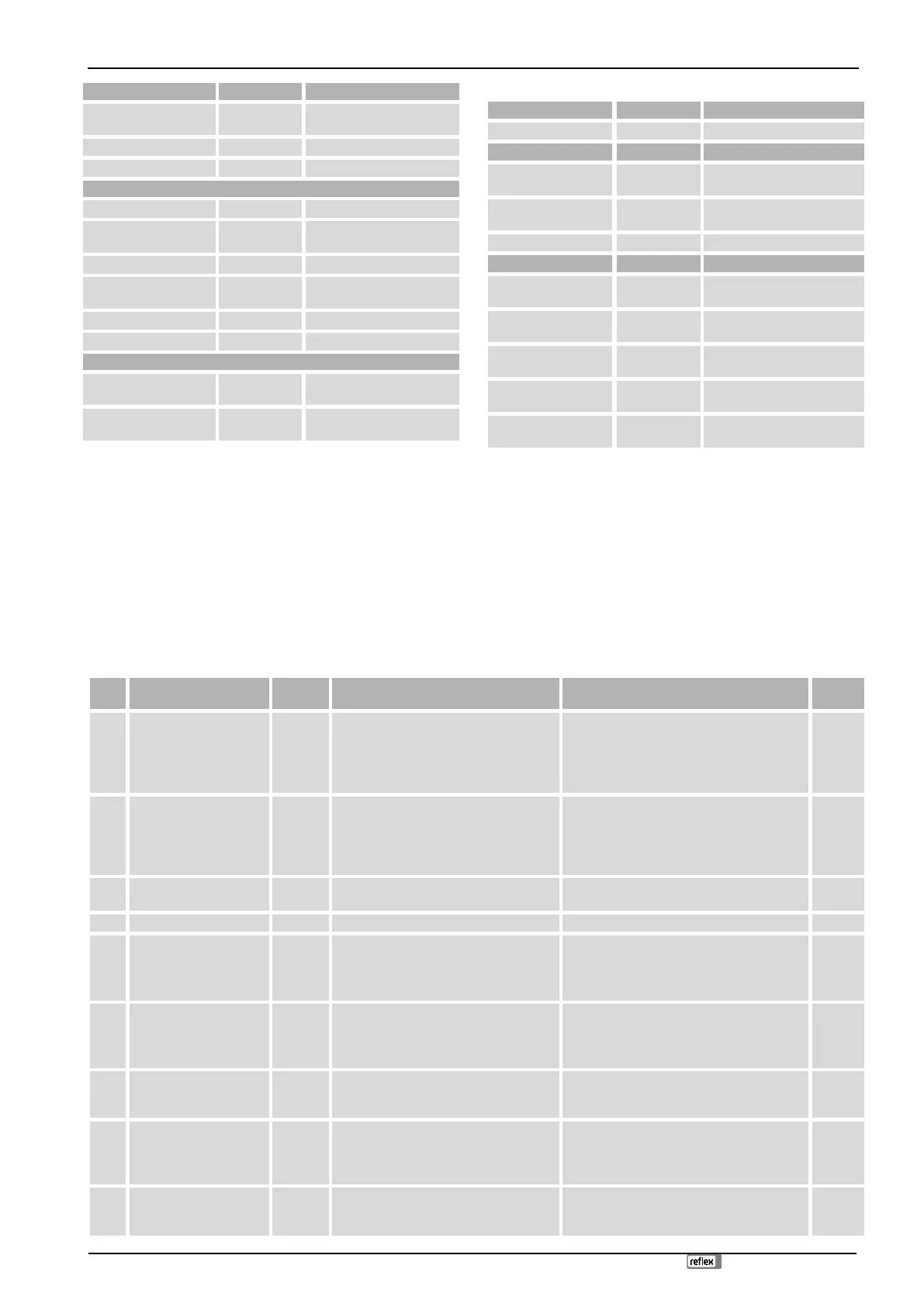

8.2.4 Messages

The display provides alarms in plain text and the ER codes listed below. Use the arrow buttons to scroll through multiple alarms displayed at the same time.

The fault memory stores the last 20 alarms for review, see chapter 8.2.1 "Customer menu" on page 36 .

Alarm causes can be eliminated by the operator or a specialist workshop. Please contact the Reflex customer service for alarms that cannot be repaired.

Note!

Some messages must be acknowledged with the "Quit" key on the operator panel of the controller (see following table), after the cause has been

corrected. All other alarms are automatically reset as soon as the cause has been eliminated.

Note!

Floating contacts, setting in the Customer menu,see chapter 8.2.1 "Customer menu" on page 36.

For "Magcontrol" setting only.

• Set value not reached.

• Water loss in the system.

• Pump fault.

• Expansion vessel defective.

• Check set value in the Customer or Service

menu.

• Check water level.

• Check pump.

• Check expansion vessel.

Dry running protection: Insufficient water

switch

• Defective.

• Not cabled.

• Triggered for too long.

• Check insufficient water switch.

• Open the degassing pipe.

• Clean the dirt trap.

• Replace the degassing valve.

Dry running protection: Insufficient water

switch has actuated too often.

• Clean the dirt trap.

• Replace the degassing valve.

Vacuum during make-up feed.

Open the make-up ball valve.

Pump disabled.

• Pump jammed.

• Pump motor defective.

• Fuse defective.

• Rotate the pump with screwdriver.

• Electrically test the pump motor.

• Replace the 10 A fuse.

• Set value exceeded.

• Water loss in the system.

• Make-up line not connected.

• Make-up rate insufficient.

• Check set value in the Customer or Service

menu.

• Check water level.

• Connect make-up line.

Continuous water loss in the system.

• Check set value in the Customer or Service

menu.

• Seal the leak in the system.

• Controller receives incorrect signal.

• Check/connect the plug connection at the

pressure transmitter

• Check the cable for damage.

• Check the pressure sensor.

For "Magcontrol" setting only.

• Set value exceeded.

• Check set value in the Customer or Service

menu.

• Set the actuating pressure of the safety valve.

Loading...

Loading...