The rear axle Section K

3 Remove the drain plug and check that the

differential

unit

rotates freely.

4

Screw the

two

circular plates

of

the tool

R.T.

8732

onto

the push rods. Insert these

through the axle tube, ensuring that the swivel

pad on each end is felt

to

locate in each side

of

the differential carrier bore. Screw the plates

up

to the axle tube flange and secure

with

the

bolts supplied. Unscrew both rods slightly

before finally clamping the plate. The

two

round

knurled gauging nuts should

be

screwed onto

the push rod

which

is facing the crown wheel

or

pinion side

of

the crown wheel,

which

for

convenience

of

explanation should

be

on the

L.H. side

of

the operator

as

he faces the axle

and referred to

as

the L.H. side throughout these

instructions.

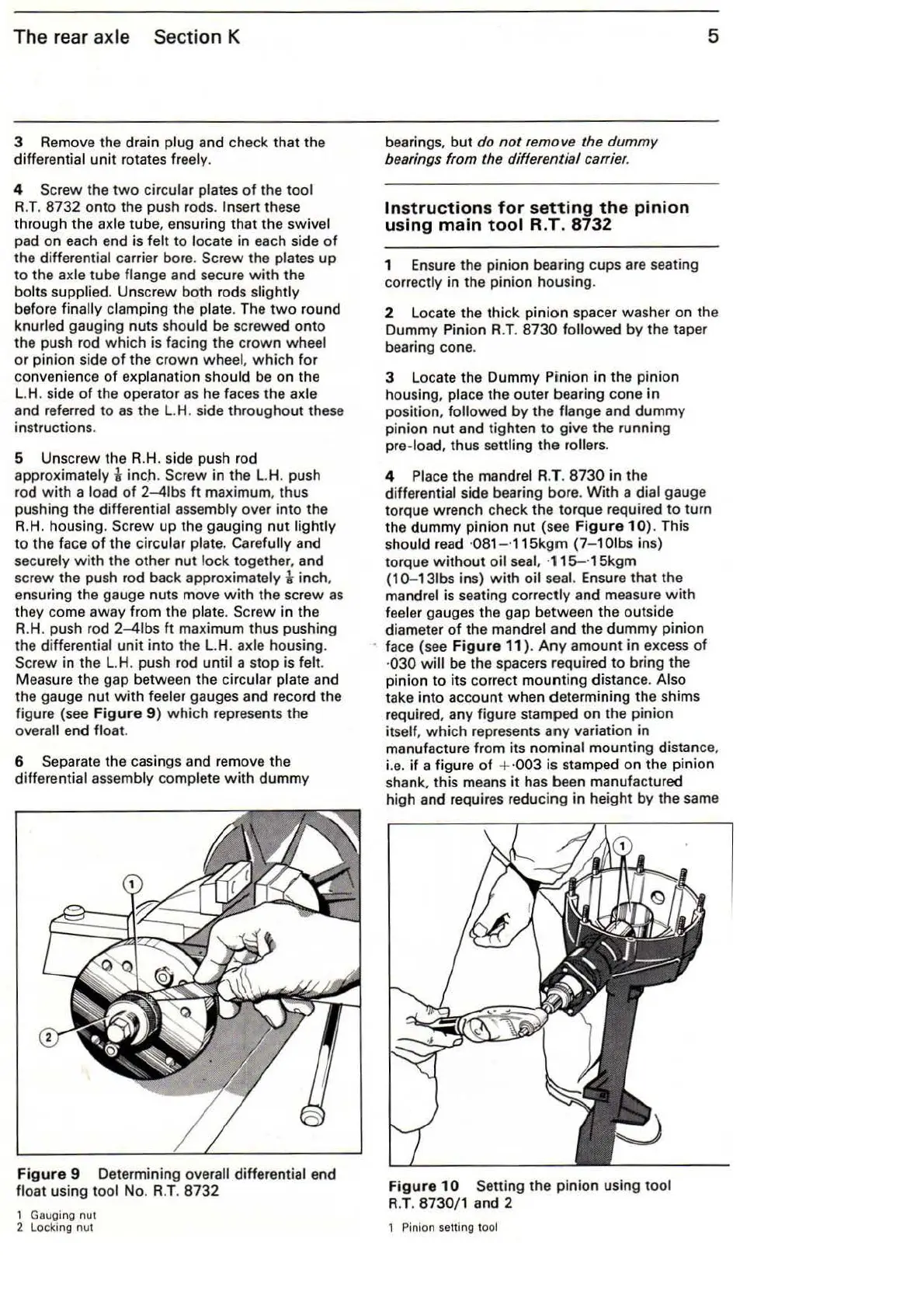

5 Unscrew the R.H. side push rod

approximately

i

inc.h

. Screw in the L.H. push

rod

with

a load

of

2-41bs

ft

maximum, thus

pushing the differential assembly over into the

R.H. housing. Screw

up

the gauging nut li

ghtly

to the face

of

the circular plate. Carefully and

securely

with

the other nut

lock

together, and

screw the push rod back approximately

i inch,

ensuring the gauge nuts move

with

the screw

as

they come away from the plate. Screw in the

R.H. p

us

h rod 2-41bs

ft

maximum thus pushing

the differential unit into the L.H. axle housing.

Screw in the

L.H

. push rod

unt

il

a stop is felt.

M

easu

re

the gap between the circular plate and

the gauge nut

with

feeler gauges and record the

figure (see

Figure

9)

which

represents the

overall end float.

6 Separate the casings and

rem

ove the

differential assembly complete

with

dummy

Figure

9 Determining overall differential end

float using tool No. R.T.

8732

1

Ga

uging

nut

2 Locking

nut

bearings,

but

do

not

remove the dummy

bearings

from

t

he

differential carrier.

Instruct

ions

for

setting

the

pi

ni

on

using

main

tool

R.T

.

8732

1 Ensure the pinion bearing cups are seating

correctly in the pinion housing.

5

2 l ocate the thick pinion spacer washer on the

Dummy Pinion R.T.

8730

followed by the taper

bearing cone.

3 l ocate the Dummy Pinion in the pinion

housing, place the outer bearing cone in

position,

followed by the flange and dummy

pinion nut and tighten

to

give the running

pre-load, thus settling the

rollers.

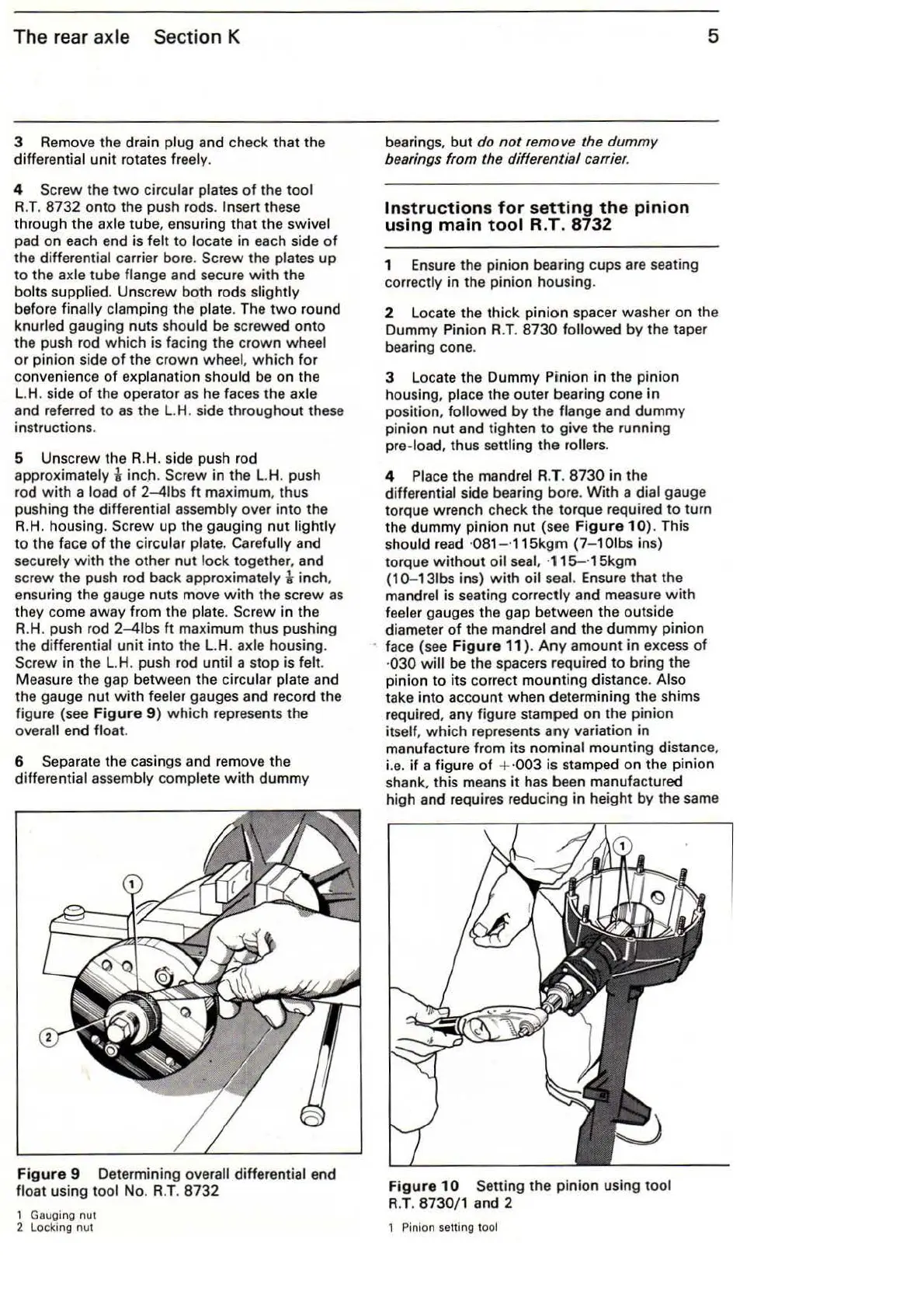

4 Place the mandrel R.T.

8730

in the

differential side bearing bore.

With

a dial gauge

torque w rench check the torque required

to

turn

the dummy p

ini

on

nut

(see

Figure

10

). This

should read

·081 -

·1

15

kgm

(7-1

Olbs

ins)

torque

without

oil

seal

, ·

115-

·15kgm

{1

0-131bs ins)

with

oi

l seal. Ensure that the

mandrel is seating correctly

an

d measure

with

feeler gauges the

ga

p between the outside

diameter

of

the mandrel and the dummy pinion

face {see

Figure

11

).

Any

amount in excess

of

·

030

will

be the spacers required to bring the

pinion

to

it

s co

rr

ect mounting

di

stan

ce

. Also

take into account when determining the

sh

ims

required, any figu

re

stamped

on

the pinion

itself,

wh

ich represents any variation in

manufacture fr

om

its nominal mounting distance,

i.e.

if

a figure

of

+ ·003 is stamped on the pinion

shank, this means

it

has been manufactured

high and requires reducing in height by the same

Figure

10

Setting the pinion using tool

R.T

. 8730/1 and 2

1 Pinion setting tool

Loading...

Loading...