The rear axle Section K

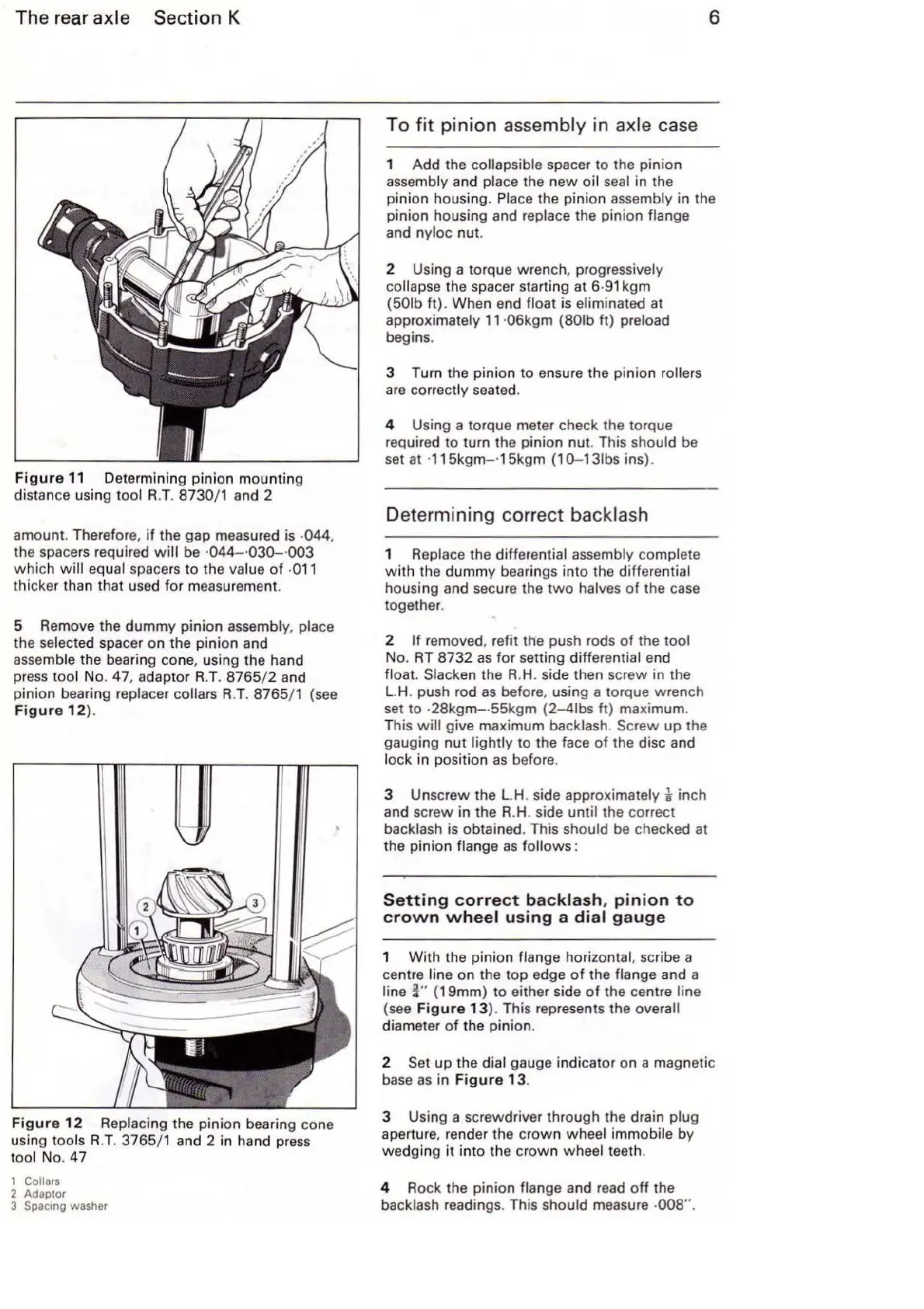

Figure

11

Determining pinion mounting

distance

us

ing tool R.

T.

8730/ 1 and 2

am

ount

. Therefore,

if

the gap measured is ·044.

the spacers required

will

be ·0

44-

·030

-·00

3

whi

ch

will

equal space

rs

to the value

of

·

011

thicker than that used for measurement.

5 Remove the dummy pinion

asse

mb

ly, place

the selected spacer on the pinion and

assemble the bearing co

ne

, using the hand

press

tool No. 47, adaptor

R.T.

8765

/ 2 and

pinion bearing replacer

collars R.T. 8765/1 (see

Figur

e

12

).

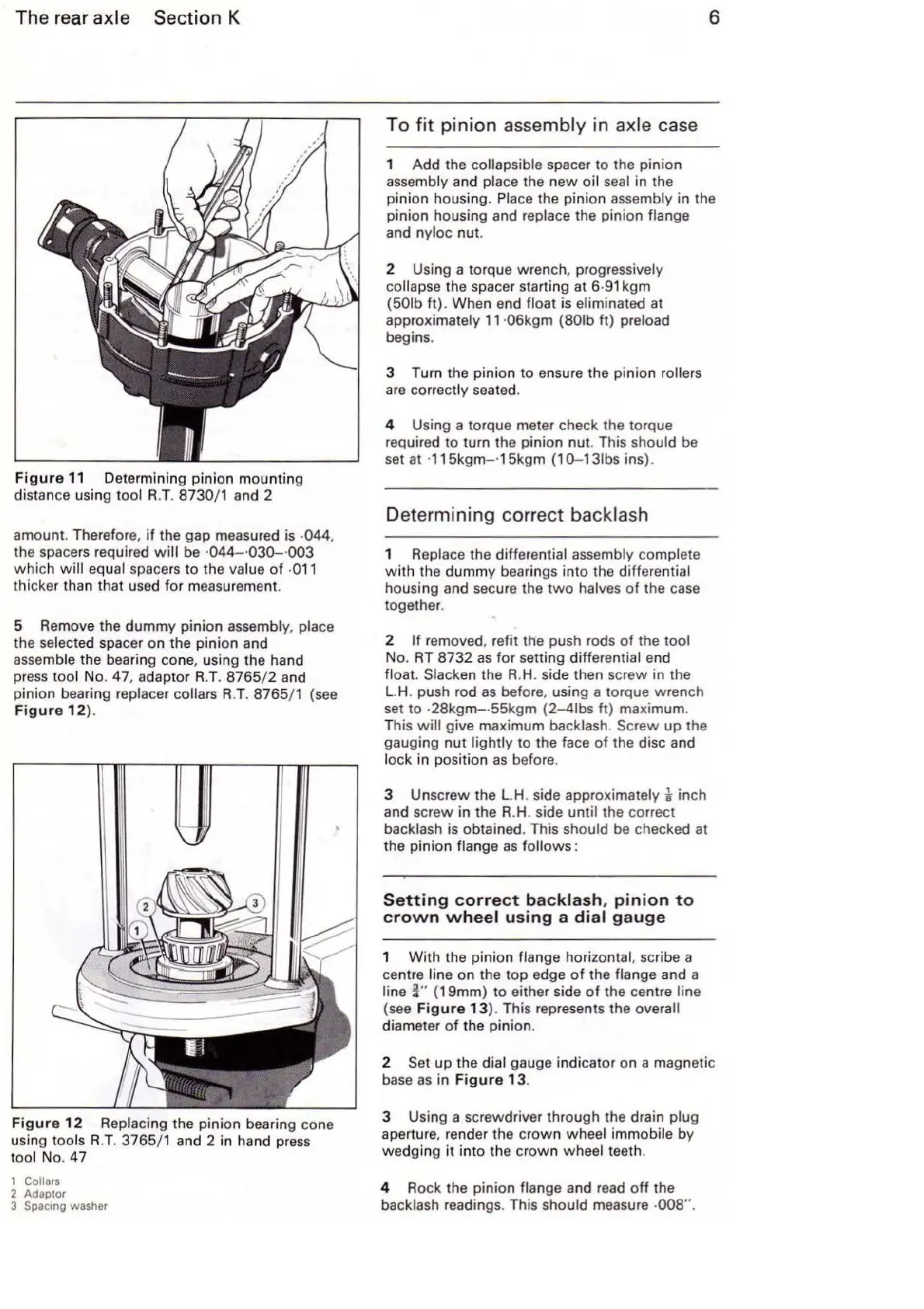

Figure

12

Replacing the pinion bearing cone

using

tools

R.T.

3765/1 and 2 in hand press

tool No. 47

1 Collars

2 Adaptor

3 Spacmg washer

6

To fit p

inio

n assembly in axle case

1 Add the collapsible spacer to the pinion

assembly

an

d place the new oil seal in the

pinion housing.

Pl

ace the pinion assembly in the

pinion housing and

replace the pinion flange

and nyloc nut.

2 Using a torque wrench, progressively

collapse the spacer starting

at

6·91

kgm

(501b

ft). When end float is eliminated at

approximately

11

·06kgm (801b ft) preload

begins.

3 Turn the pinion to ensure the pinion

rollers

are co

rr

ectly seated.

4 Using a torque meter check the torque

required to turn the pinion nut. This should

be

set at ·115kgm- ·15kgm

(1

0-131bs ins).

Determining correct backlash

1 Replace the differential assembly complete

with

the dummy bearings into the differential

housing and secure the

two

halves

of

the

case

together.

2

If

removed, refit the push rods

of

the tool

No.

RT

8732

as

for

setting differential end

float. Slacken the

R.H

. side then screw in the

L.H

. push rod

as

before, using a torque wrench

set to

·2

8kgm-

·55kgm (2-41bs ft) maximum.

This

will

give maximum backlash. Screw

up

the

gauging

nut

lightly to the face

of

the disc and

lock in position

as

before.

3 Unscrew the L.H. side approximately k inch

and screw in the R.H. side

until the correct

backlash is obtained. This

should be checked at

the pinion

flange

as

follows

:

Setting

correct

ba

ckl

ash

,

pinion

to

crown

wheel

using

a

dial

gauge

1

With

the pinion flange horizontal, scribe a

centre

line on the top edge

of

the flange and a

line

i"

(19mm) to either side

of

the centre line

(see

Figure

13). This represents the overall

diamet

er

of

the pinion.

2

Set

up

the dial gauge indicator on a magnetic

base

as

in

Figur

e

13

.

3 Using a screwdriver through the drain

plug

aperture, render the

crown

wheel immobile by

wedging

it

into the

crown

wheel teeth.

4 Rock the pinion

flange and read

off

the

backlash readings. This

should measure ·008".

Loading...

Loading...