Fuel system Section P

4 Slacken jubilee clip securing rubber tank

hose

to

filler tube.

5 Disconnect fuel supply pipe at sleeve

connector, located on

R.H

. chassis side member.

6 Remove nut and washer securing fuel tank

to

L.H

. and R.H. support straps.

7 Bend retaining straps outwards to clear tank

mounting studs. Take

ca

re

n

ot

to

damage the

mounting stud threads.

8

Carefully lower tank, disconnect

se

nder unit

lead, and remove fuel tank from

rear

of

vehicle.

9 Replace in rever

se

order.

Fuel tank sender unit

If

faulty readin

gs

are

suspected on the fuel

indicator check the indicator and sender unit

as

follows:

1

Rem

ove fuel tank

as

previously described.

2 Twist sender unit locking ring to r

elease

from tank location and w ithdr

aw

sender unit

(see

Figure

1

).

3 With sender unit lead still disconnected,

switch on vehicle ignition. The fuel indicator

needle should then

be

at the empty mark.

4

Earth

sender unit lead. The fuel indicator

needle should then

be

at the full mark, a

nd

this

will

confirm that the fuel indicator

is

functioning

correctly.

5 Reconnect sender unit lead and manually

operate the float

le

ve

r. With the float lever at

its bottom stop the

fuel indicator needle should

be

at the empty mark. With the float

le

ver at its

top

stop the fuel indicator

will

re

ad

full.

Any

deviation from these readings

will

confi

rm

that

the sender

unit

is faulty and will need replacing.

Fuel pump

Testing

the

fuel

pump

Providing there

are

no leaks or obstructions in

the fuel

line, a quick check on the fuel pump

efficien

cy

ca

n be made

as

follows:

1 Disconnect carburettor feed pipe at the

fuel pump

outlet.

2 Connect a slave pipe

to

the pump outlet

and place in a clean jar.

3

Crank the engine, when a well-defined

spurt

of

fuel should

be

apparent for

each

revolution

of

the engine.

If

the pump does not

operate

satisfactorily remove, dismantle and

fit

the necessary spare parts which

are

available

in a

repa

ir kit Part No. 11858.

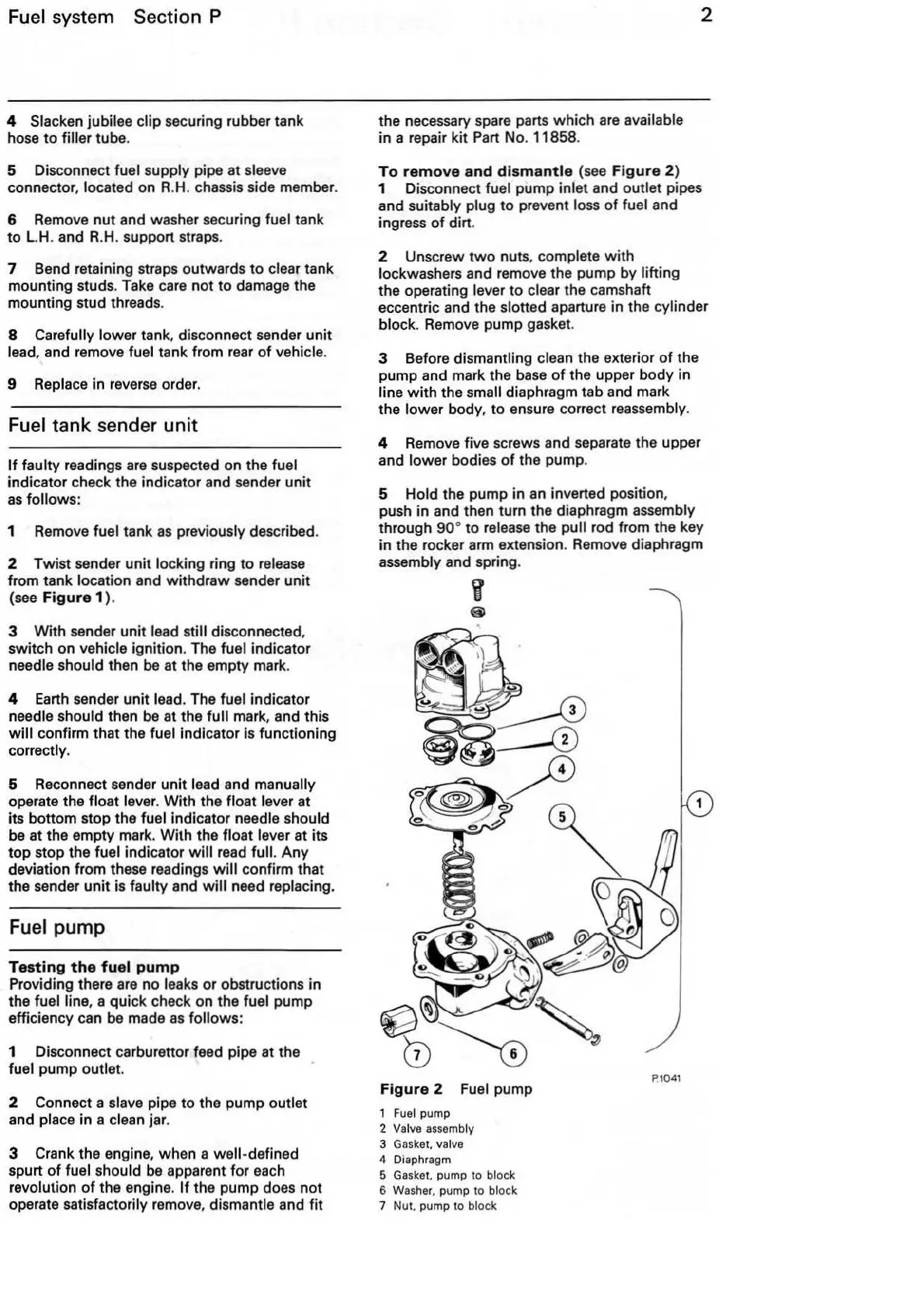

To

remove

and

dismantle

(see

Figure

2)

2

1 Disconne

ct

fuel pump inlet and outlet pipes

and suitably

plug

to

prevent loss

of

fuel and

ingress

of

dirt.

2 Unscrew

two

nut

s,

complete

with

lockwashers and remove the pump by lifting

the operating lever

to

clear the camshaft

eccentric and the slotted aparture in the cylinder

block. Remove pump gasket.

3 Before dismantling clean the exterior

of

the

pump and mark the

base

of

the upper body in

line

with

the small diaphragm tab and mark

the

lower body, to ensure correct r

easse

mbl

y.

4 Remove fi

ve

screws and

sepa

rate the upper

and lower bodies

of

the pump.

5

Hold the pump in

an

in

verted position,

push

in

and then turn the diaphragm

asse

mbly

through

90

° to release the pull rod from the key

in the rocker arm extension. Remove diaphragm

assembly

an

d spring.

Figure

2 Fuel pump

1

Fuel

pump

2

Valve assembly

3

Gaske

t. valve

4 Diaphragm

5 Gasket. pump to block

6 Washer, pump to block

7 Nut. pump to block

1

P.10

41

Loading...

Loading...