Ele

ctri

cs

Section T

Igni

ti

on system

The ignition system comprises battery, ignition

sw

itch, coil, distributor and sparking plugs

as

shown in

Figur

e 1.

If

trouble is experienced

with

the ignition the

components shown in Figure 1

should be

systematically checked

to

diagnose the fault.

Particular

attention should be given to the

cleanlin

es

s and security

of

the earth braids.

for

if after inspecting the various electrical

components the ignition system still

fa

ils

to

function correctly, a loose braid could

be

the

cause.

The distributor is described in

full bel

ow

but

for

details

of

the other i

gnit

ion system components

refer

to

the General Electrics on page 18.

Distributor

D

esc

ripti

on

T

he

distributor is mounted on the

R.H

. side

of

the cylinder block and is driven by an offset

dog

from t

he

camshaft. Ignition advance is

mechanically controlled, according

to

engine

speed, by governor weights inside the distributor

body

. Distributor rotation is anti

-c

lockwise

viewed from above.

Lubri

c

ati

on

T

he

cam and contact breaker plate pivots and

bushin

gs,

whe

n assembling after overhaul.

sh

ould be lubricated

with

petroleum jelly. T

he

ca

m spi

nd

le governor weights and breaker arm

pivots

should

be

l

ub

ricated

with

engine oil every

3,000 miles (5,000km). To lubricate cam spindle

remove the rotor and apply

two

drops

of

oil

through the apertures in the breaker plate. Only

a film

of

engine oil should

be

applied to the

breaker arm pivot. ensuring that none

contaminates the distributor poin

ts

.

Caution: Do not over lubricate any part

of

the

distributor.

T

he

presence

of

dirt, oil

or

water on the

ignition

points, the central carbon brush,

or

on

the contact segments in the distributor

cover,

will

cause erratic running

or

may even prevent

the engine from running at

al

l.

Contact b

rea

ker po

int

s

To

a

dju

st

1 Remove the distributor cap and rotor arm.

2 Tu

rn

the engi

ne

so that the

hee

l

of

the

contact breaker is on the highest poi

nt

of

the

cam.

(It may

be

necessary to remove the

spa

rking plugs

to

eliminate the resistance caused

by compression.)

2

P1062

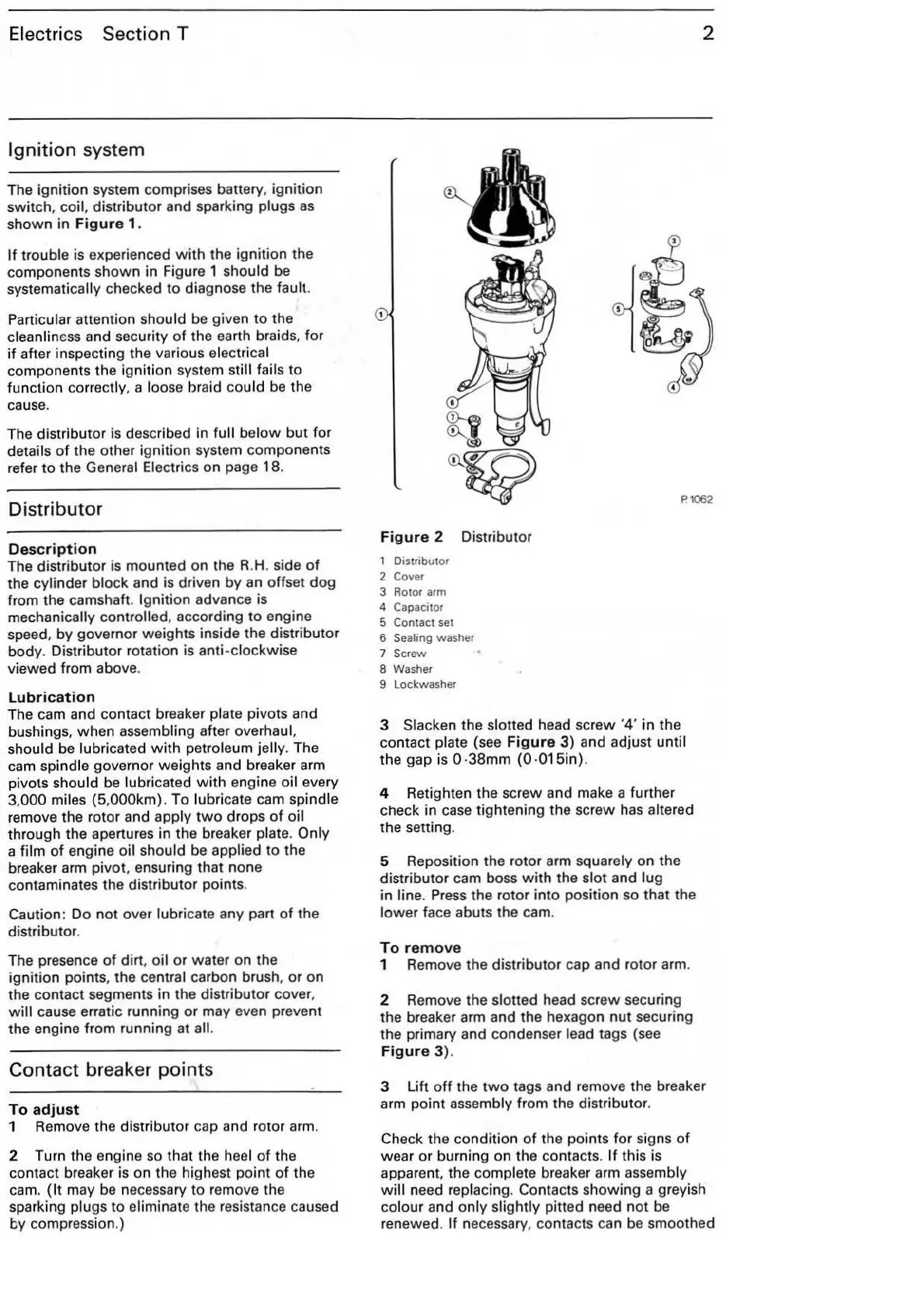

Fi

gur

e 2 Distributor

1 Distributor

2

Cover

3 Rotor arm

4 Capacitor

5

Contact set

6

Sealing washer

7

Screw

8 Washer

9 Lockwasher

3 Slacken the slotted head screw '4' in the

conta

ct

plate (see

Figur

e

3)

and adjust until

the gap is

0·38

mm (0 ·015in).

4 Retighten the scr

ew

and make a further

check in

case

tightening t

he

screw

has

altered

the setting.

5 Reposition the rotor arm

squarely on the

distributor cam boss

with

the sl

ot

and lug

in line.

Press

the rotor into position so that the

lower

face abuts the cam.

To

r

em

o

ve

1 Remove the distributor cap and rotor arm.

2 Remove the

slotted head screw securing

the breaker arm and the hexagon

nut

securing

the primary and condenser

lead tags (see

Figur

e

3)

.

3 Lift

off

the

two

tags and remove the breaker

arm point

assembly from the distributor.

Check the condition of the points

for

signs

of

wear

or

burning on the contacts. If this is

apparent. the

complete breaker arm assembly

will

need replacing. Contacts showing a greyish

colour and only slightly pitted need

not

be

renewed.

If

necessary, contacts can

be

smoothed

Loading...

Loading...