The

brakes

Section L

1

Description

The braking system employs

two

leading shoes

on the front

wheel, hydraulica

ll

y operated. The

rear brakes. also hydraulic, use a leading and

trailing shoe. A mechanical handbrake linkage is

provided

to

the rear brakes only.

The br

ake

pedal, connected directly to the

master cylinder via short push

r

od

, also

operates a stop

light switch mounted on the

pedal bracket assembly.

Routine ma

int

enance and adjustment

Check the level

of

the brake master cylinder

fluid weekly and top up if necessary. Every

3,000 miles

(5

,000km)check and adjust brakes

and hydraulic system, and grease hand brake

cable.

Front brake adjustment

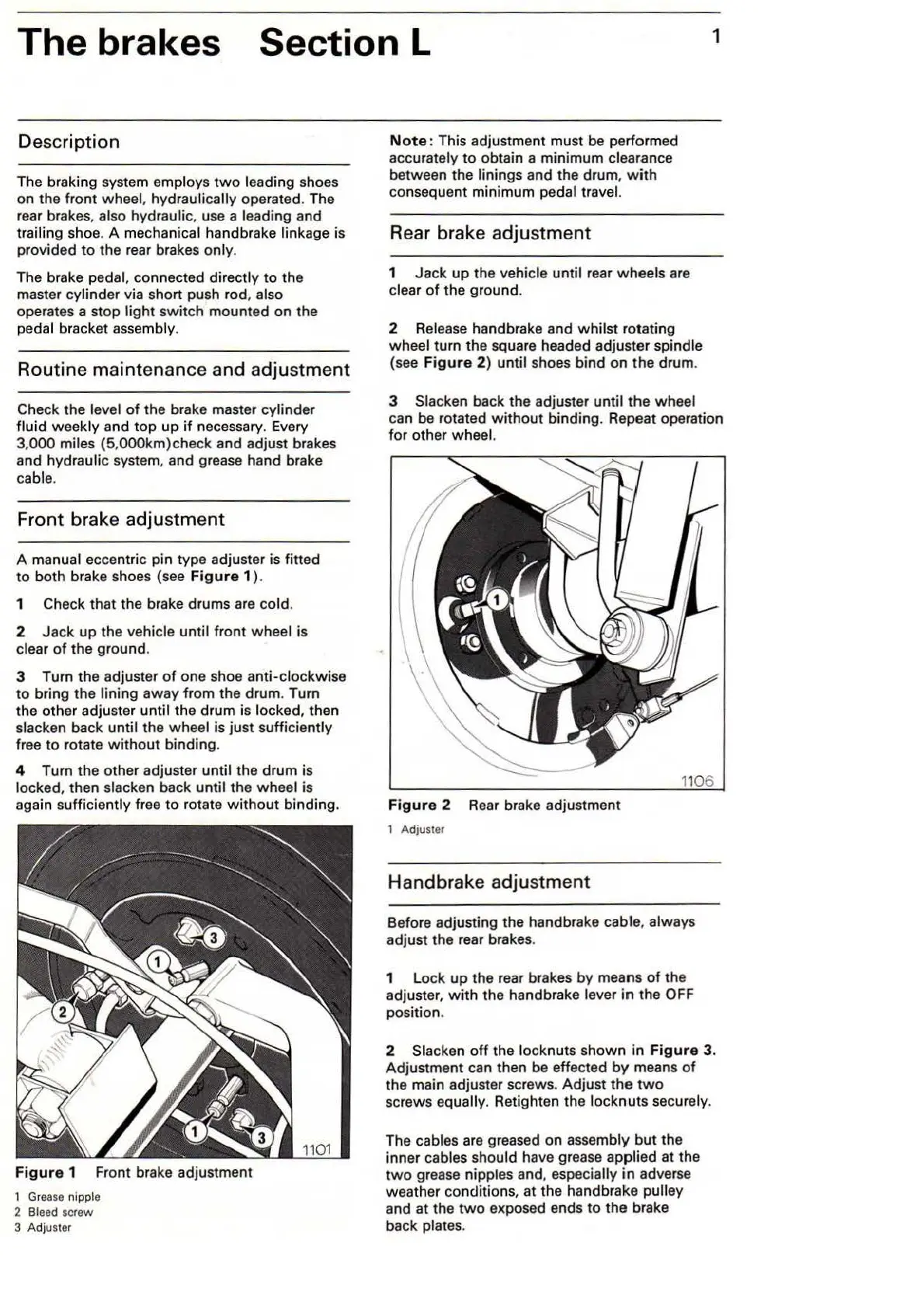

A manual eccentric pin type adjuster is fitted

to both brake shoes (see

Figure

1 ).

1 Check that the brake drums

are

cold

.

2 Jack up the vehicle

until front wheel is

clear

of

the ground.

3 Turn the adjuster

of

one shoe anti-clockwise

to

bring the lining away from the drum. Turn

the other adjuster until the drum is

locked, then

slacken back

until the wheel is just sufficiently

free

to

rotate

without

binding.

4 Turn the other adjuster until the drum is

locked. then slacken back until the wheel is

aga

in sufficiently free

to

rotate

without

binding.

Figure

1 Front brake adjustment

1 Gr

ease

nipple

2 Bleed screw

3 Adju

ste

r

N

ote:

This adjustment

mu

st be performed

accurately

to

obtain a minimum clearance

between the linings and the drum.

with

consequent minimum pedal travel.

Rear brake adjustment

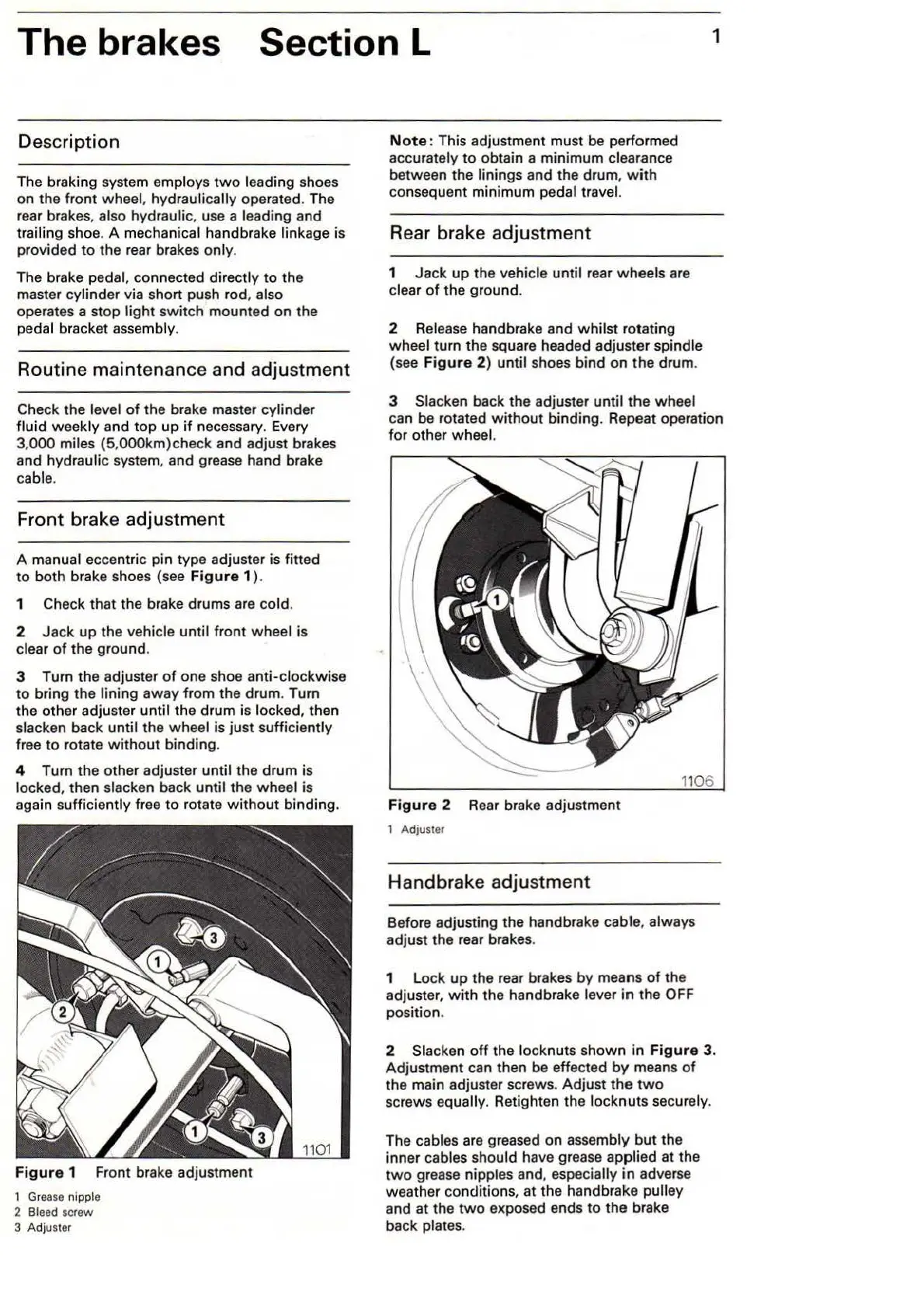

1 Jack

up

the vehicle until rear wheels are

clear

of

the ground.

2 Release handbrake and whilst rotating

wheel

tur

n the square headed adjuster spindle

(see

Figure

2) until shoes bind on

the

drum.

3 Slacken back the adjuster

until the wheel

can be rotated

without

binding. Repeat operation

for other wh

ee

l.

Fi

gure

2

Rear

brake adjustment

1 Adjuster

Handbrake

ad

ju

stment

Before adjusting the handbrake cab'le, always

adjust the rear brakes.

1 Lock

up

the rear brakes by means

of

the

adjuster, with the handbrake lever

in

the OFF

position.

2 Slacken

off

the

lo

ck

nut

s shown

in

Figure

3.

Adjustment can then be effected

by

means

of

the main adjuster screws. Adjust

the

two

screws equally. Retighten the locknuts securely.

The cables are greased on assembly

but

the

inner cables should have grease applied at the

two

grease nipples and, especially

in

adver

se

weather condition

s,

at the handbrake pulley

and at the

two

exposed ends to the brake

back plates.

Loading...

Loading...