Electrics Section T

Starting system

The starting system comprises battery, ignition

switch, solenoid and starter motor,

as

shown

in

Figure

5.

If

the starter fails

to

operate when the ignition

is switched

on

the components in

Figure

5

should

be

systematically checked to diagnose

the fault. Examine the starter pinion which may

be jamming

in

mesh

with

the flywheel ring gear.

It

can be released by turning the squared end

of

the pinion shaft in

an

anti-clockwise direction.

Check that the battery is

in

a good state

of

charge and the terminals free from corrosion.

The condition and security

of

the earth braids

is also important. The starter solenoid could also

be at fault. When the ignition is switched on the

starter motor pinion makes a distinct sound

when meshing

with

the flywheel ring gear and

if

this is

not

apparent, a faulty solenoid could

be indicated.

If

the components

of

the starting system are

found to be functioning cor

re

ctly this would

indicate that the fault lies in the ignition or

charging systems (see

Figure

1 and

Figure

7).

The starter motor and testing procedure is

described below

but

for details

of

the other

starting system components refer to the General

Electrics on page

18

.

Starter

motor

Description

The

starte~

motor is a

fou

r pole, four brush

machine

with

inertia drive and is

se

cured in the

R.H

. side to the rear engine plate and gearbox

bell housing.

To

remove

starter

motor

(see

Figure

6)

1 Disconnect battery.

2 Remove oil

filter.

3 Disconnect starter motor lead and remo

ve

two

i UN F bolts, washers, lockwashers and

hexagon nuts securing the motor

to

the rear

engine plate and

bell housing.

4 Remove starter motor from the vehicle.

5 Replace

in

reverse order.

Starter

motor

specification

lo

ck torque

Running torque (at

1,000 rpm)

ligh

t running current

Brush spring pressure

6

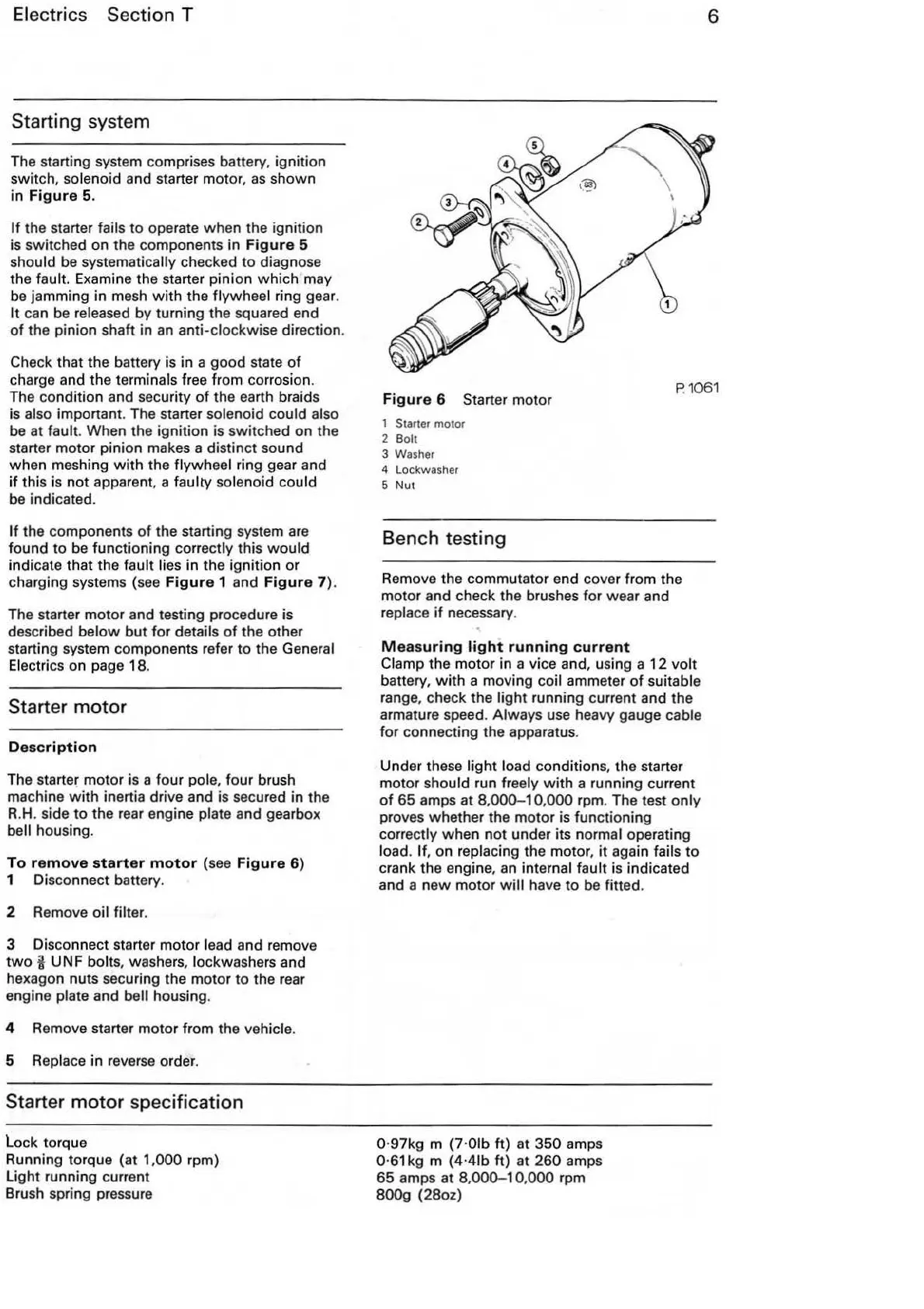

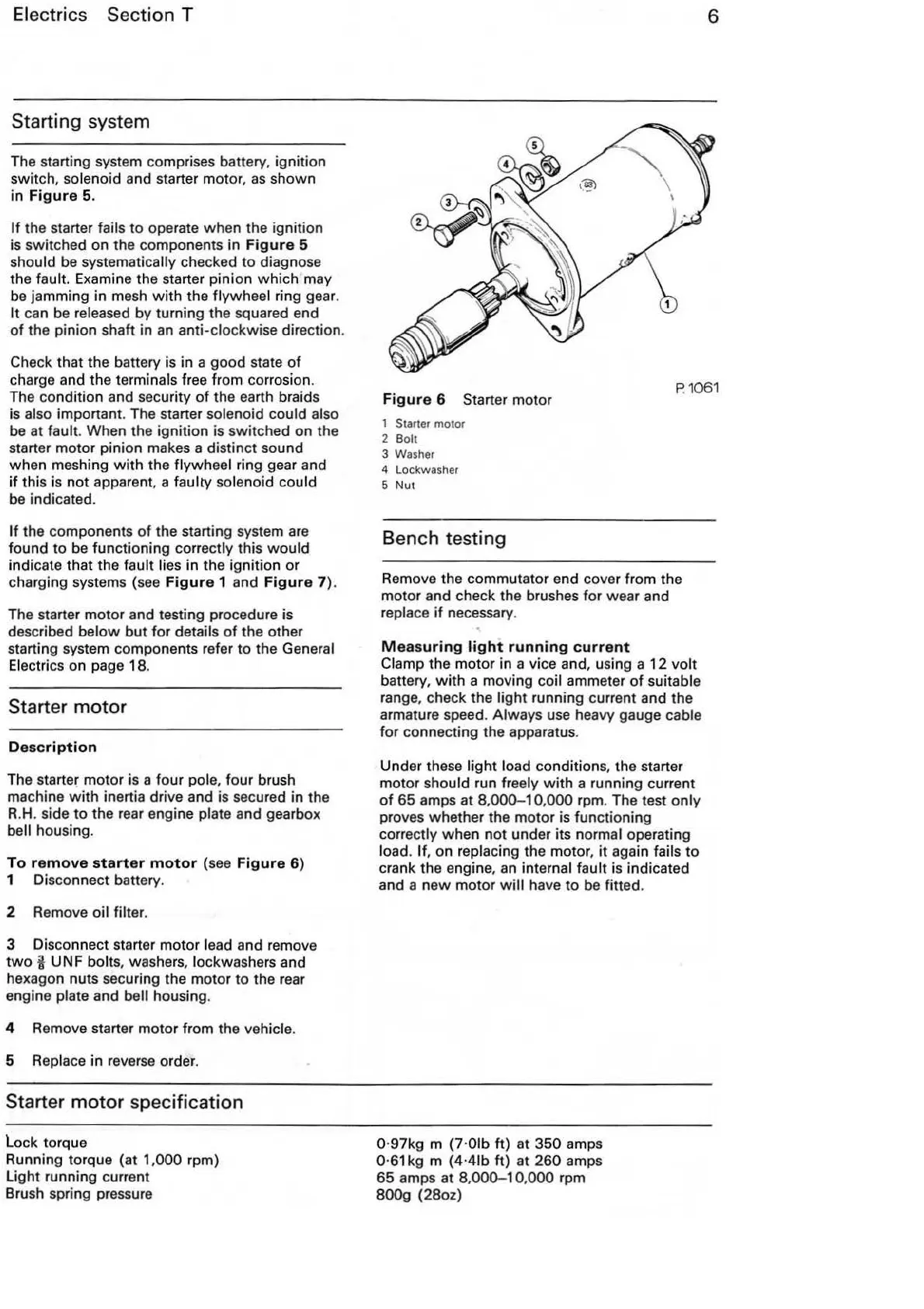

Figure

6 Starter motor

P.

1

061

1 Starter motor

2

Bolt

3 Washer

4 Lockwasher

5

Nut

Bench testing

Remove the commutator end cover from the

motor and check the brushes for wear and

replace

if

necessary.

Measuring

light

running

current

Clamp the motor in a vice and, using a

12

volt

battery, with a moving coil ammeter

of

suitable

range, check the li

ght

running current and the

armature speed. Always use heavy gauge cable

for connecting the apparatus.

Under these light load condition

s,

the starter

motor should run freely

with

a running current

of

65

amps at 8,000-1 0,

000

rpm. The test

only

proves whether the motor is functioning

correctly when not under

its

normal operating

load.

If

, on replacing the motor, it again fails

to

crank the engine,

an

int

ernal fault is indicated

and a new motor

will

have

to

be fitted.

0·97kg m (7·01b

ft)

at 350 amps

0·

61

kg m (4·41b ft) at 260 amps

65 amps at

8,

000-10

,

000

rpm

800g (28oz)

Loading...

Loading...