The brakes Section L

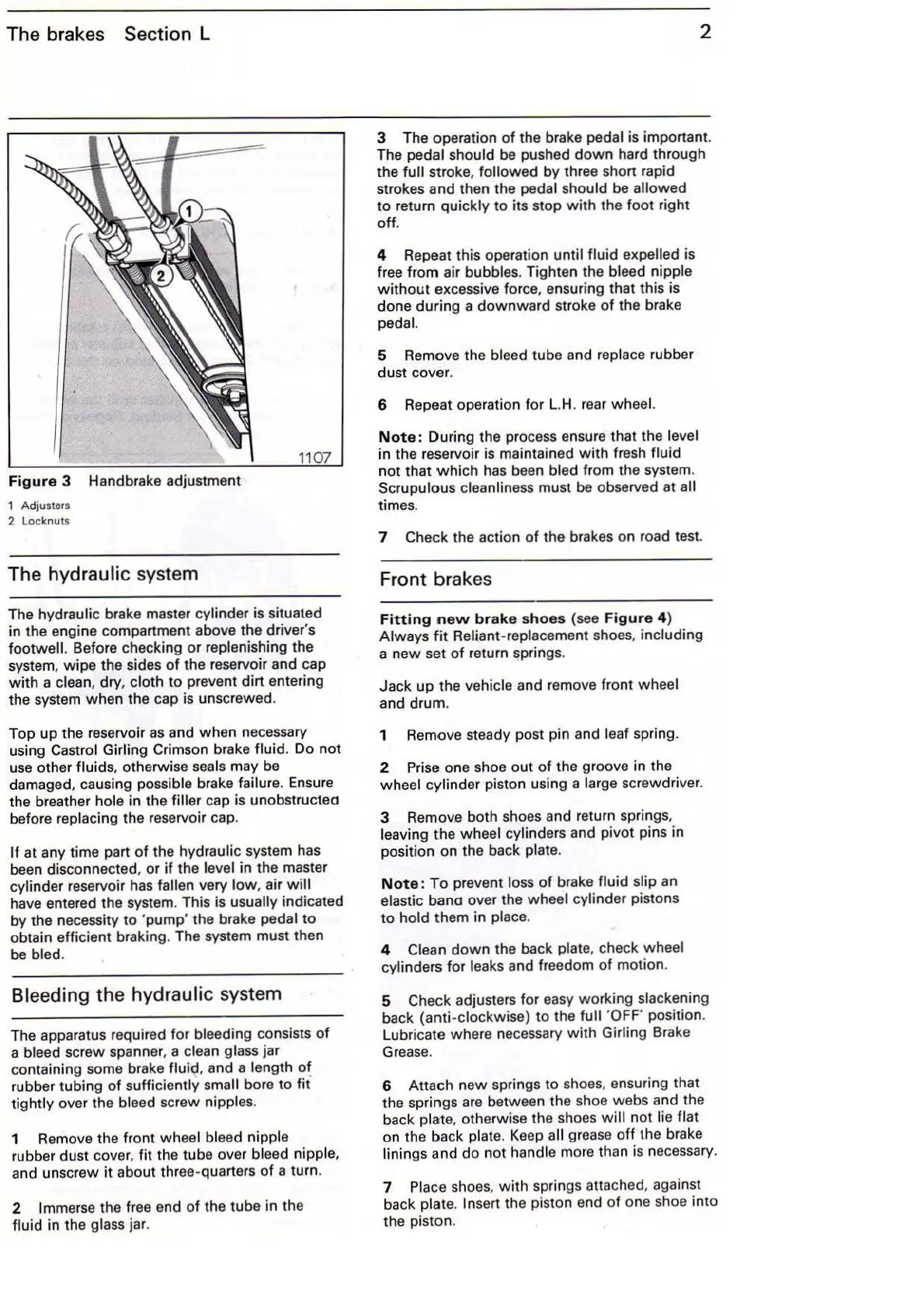

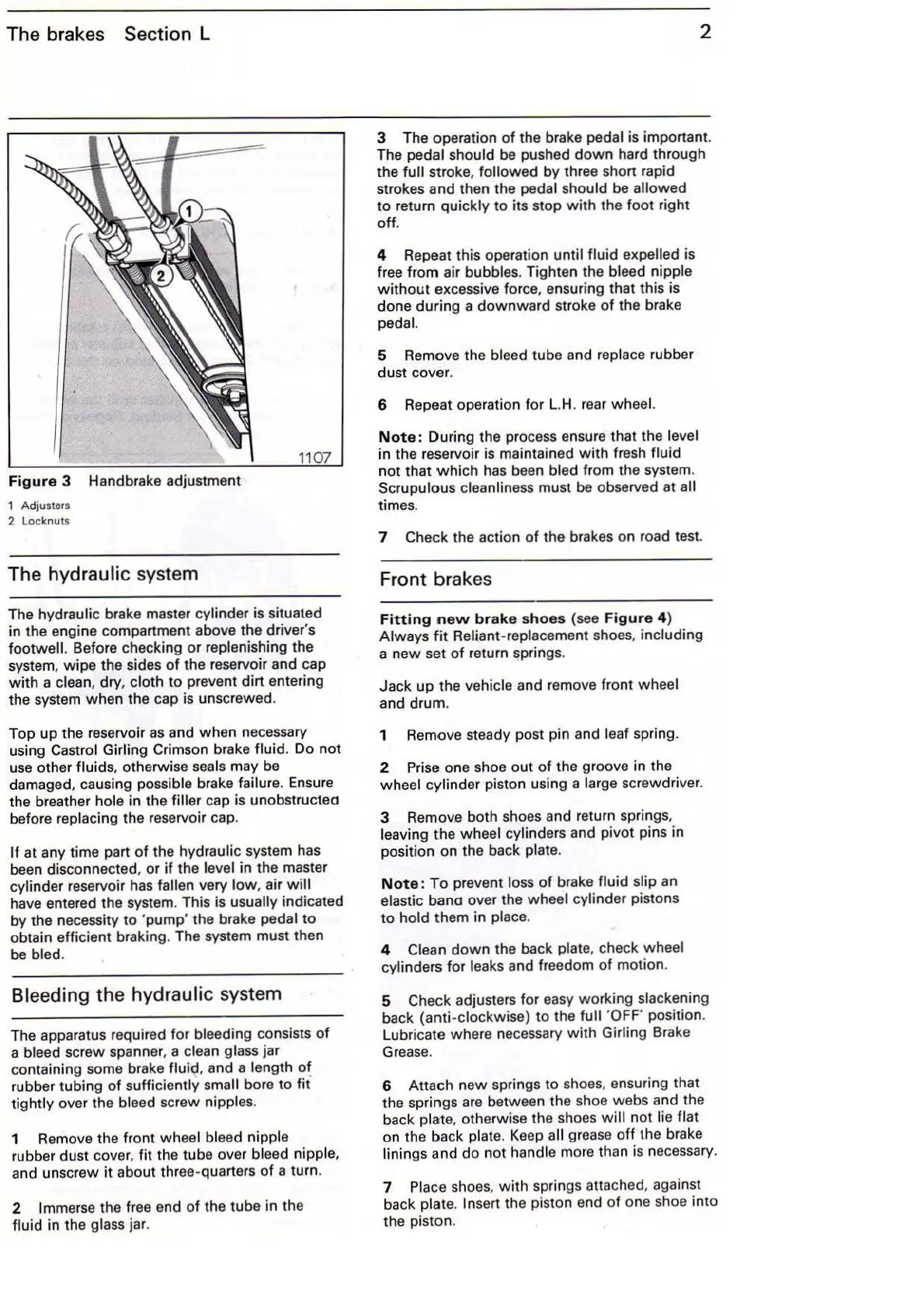

Figur

e 3 Handbrake adjustment

1 Adjusters

2 Locknuts

The hydraulic system

The hydraulic brake master cylinder is s

itu

ated

in

the engine compartment above the driver's

footwall. Before checking

or

replenishi

ng

the

system,

wipe

the sides

of

the reserv

oi

r and cap

with

a clean, dry, cloth

to

prevent dirt entering

the system

when

the cap is unscrewed.

Top

up

the reservoir

as

and

when

necessary

using Castro! Girling Crimson brake

fluid

. Do

not

use other fluids, otherwi

se

seals may be

damaged, causing possible brake

failure. Ensure

the breather

hole in the filler cap is unobstructea

before replacing the reservoir cap.

If at any time part

of

the hydraulic system has

been disconnected, or

if

the level in the master

cylinder reservoir has

fallen very

low

, air

will

have entered the system. This is usually indicated

by the necessity to 'pump' the brake pedal

to

obtain efficient braking. The system must then

be bled.

Bleeding the hydraulic system

The apparatus required

for

bleeding consists

of

a bleed screw spanner, a clean glass jar

containing some brake

flu

id

, and a length

of

rubber tubing

of

sufficiently small bore to

fit

tightly

over the bleed screw nippl

es.

1 Remove the front wheel bleed nipple

rubber dust cover, fit the tube over bleed nipple,

and unscrew

it

about three-quarters

of

a turn.

2 Immerse the fr

ee

end

of

the tube in the

fluid in the glass j

ar

.

2

3 The operation

of

the brake pedal is important.

The pedal should

be

pushed

down

hard through

the

full stroke, followed by thr

ee

short

ra

pid

strokes and then the pedal should be

allowed

to

return quickly to its stop

with

the

foot

right

off

.

4 Repeat this operation

until fluid expelled is

free from air

bubb

les. Tighten the bleed nipple

without

excessive force, ensuring that this is

done

during

a

downward

stroke of the brake

pedal.

5 Remove the bleed tube and replace rubber

dust cover.

6 Repeat operation for L.H.

re

ar

wheel.

Note

: During the process ensure that the level

in the reservoir is maintained

with

fresh fluid

not

that

which

has been bled from the system.

Scrupulous cleanlin

ess

must

be

observed at all

times.

7 Check the action

of

the brakes on road test.

Front brakes

Fitting

new

brake

s

ho

es (see

Figure

4)

Always

fit

Reliant-replacement shoes, including

a

new

set

of

return springs.

Jack

up

the vehicle and remove front wheel

and

drum

.

1 Remove steady post pin and

leaf spring.

2 Prise one shoe

out

of

the groove in the

wheel cylinder piston using a large screwdriver.

3

Remov.e

both shoes and return springs,

leaving the wheel cylinders a

nd

pivot pins in

position on the back plate.

Note

:

To

prevent loss

of

brake fluid slip an

elastic bana over the wheel cylinder pistons

to

ho

ld them in place.

4 Clean

down

the back plate, check wheel

cylinders for leaks and freedom

of

motion.

5 Check adjusters for easy working slackening

back (anti-clockwise) to the

full 'OFF' position.

Lubricate where necessary

with

Girling Brake

Grease.

6 Attach new springs

to

shoes, ensuring that

the springs are between the shoe webs and the

back

plate, otherwise the shoes

will

not

lie flat

on the back plate.

Keep

all grease

off

the brake

linings and do

not

handle more than

is

ne

cessary.

7

Pla

ce shoes,

with

springs attached, against

back plate.

Insert the piston end

of

one shoe

into

the piston.

Loading...

Loading...