Electrics Section T

Figure

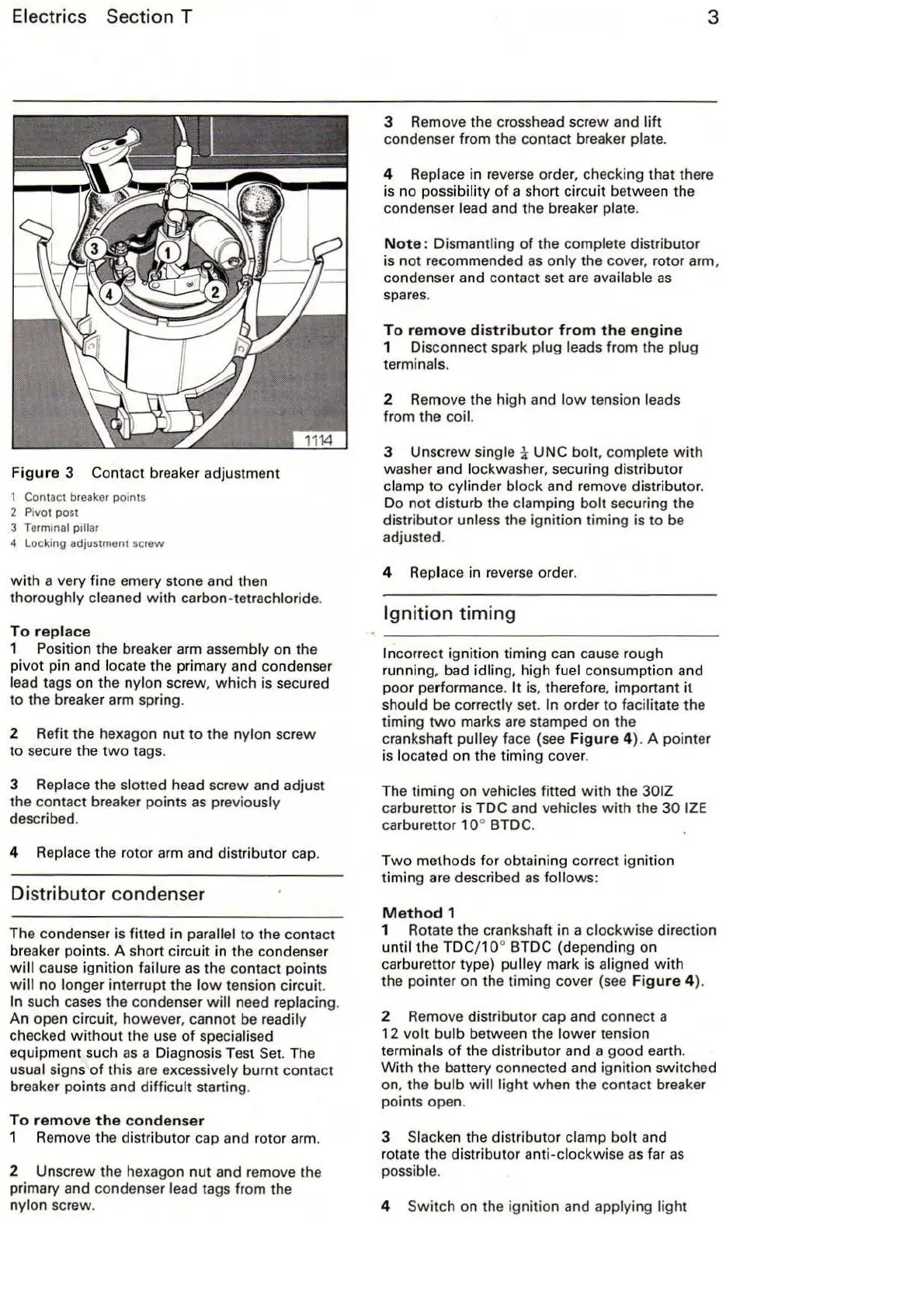

3 Contact breaker adjustment

1 Contact breaker points

2 Pivot post

3

Terminal pillar

4 Locking adjustment screw

with

a very fine emery stone and then

thoroughly

cleaned with carbon-tetrachloride.

To

replace

1 Posi

ti

on the breaker arm assembly on the

piv

ot

pin and locate the primary and conden

se

r

lead tags on the n

ylo

n screw,

which

is secured

to the breaker arm spring.

2 Refit the hexagon nut

to

the

ny

lon screw

to

secure the

two

tags.

3 Replace the slotted head screw and adjust

the contact breaker points

as

previously

described.

4

Replace the rotor arm and distributor cap.

Distributor condenser

The condenser is fitted in parallel to the contact

br

eaker points. A short circ

uit

in the condenser

will

cause ignition failure

as

the contact points

will

no

longer interrupt the

low

tension circuit.

In such cases the condenser

will

need replacing.

An open

circui

t,

however, cann

ot

be

readily

checked w

it

hout the use

of

specialised

equipment such

as

a Diagnosis Test Set. The

usual signs

of

this

are

excessively burnt contact

breaker po

int

s and

difficult

starting.

To

remove

the

condenser

1 Remove the distributor cap and rotor ar

m.

2 Unscrew the hexagon

nut

and remove the

primary and condenser

lead tags from the

nylon screw.

3 Remove the crosshead screw and

lift

co

ndenser from the contact breaker plate.

3

4 Replace in reverse order, checking that there

is

no

possibility

of

a short circuit between the

condenser

l

ea

d and the breaker plate.

Not

e:

Dismantling

of

the complete distributor

is

not

recommended

as

only the cover, rotor arm,

condenser and contact set

are

available

as

spares.

To

remove

distributor

from

the

engine

1 Disconnect spark plug leads from the plug

terminals.

2 Remove the high and

low

tension leads

from the coil.

3 Unscrew single i UNC

bolt

, complete with

washer and

lockwasher, securing distr

ib

utor

clamp

to

cylinder block and remove distributor.

Do not disturb the clamping

bolt

securing the

distributor

un

less the ignition timing is to be

adjusted.

4

Rep

lace in reverse ord

er.

Ignition

timing

Incorrect ignition timing

ca

n cause rough

running, bad

idling, high fuel consumption and

poor performance.

It

is, therefore, important

it

should be correctly set. In order to facilitate the

timing

two

marks

are

stamped on the

crankshaft

pulley face (see

Figure

4). A pointer

is

located on the timing cover.

The timing on vehicles fitted w ith the

301Z

carburettor is TDC and vehicles

with

the

30

IZE

carburettor

10

° BTDC.

Two

methods for obtaining correct ignition

timing are described

as

follows

:

Method

1

1 Rotate the crankshaft in a clockwise direction

until

the

TDC/1 0° BTDC (depending on

carburettor type)

pulley mark is aligned

with

the pointer on the timing cover (see

Figure

4).

2 Remove distributor cap and connect a

12

volt

bulb between the

lower

tension

terminals

of

the distributor and a

good

earth.

With

the battery connected and i

gnit

ion switched

on, t

he

bulb will light when the contact breaker

points open.

3

Slacken the distributor clamp

bolt

and

rotate the distributor anti-clockwise

as

fa

r

as

possible.

4

Switch

on the ignition and applying light

Loading...

Loading...