The engine Section F

19

Remove plug and connect petrol supply

pipe at fuel pump.

20

Reconnect choke cable at carburettor and

throttle cable at pedal.

21

Refit air cleaner.

22

Reconnect coil high and

low

tension leads.

23

Reconnect oil pressure indicator lead at

cylinder block.

24

Reconnect temperature gauge sender unit

lead at thermostat housing.

25

Reconnect starter motor lead.

26

Refit alternator and connect leads.

27 Refill engine and gearbox

with

recommended oil.

28

Refill the cooling system.

29 Reconnect battery.

Operation

2-

Flywheel and ring

gear

removal and replacement

1 Remove gearbox (see Section G - The

Gearbox).

2 Unscrew six set screws,

complete

with

lockwashers, and remove clutch assembly from

the

flywheel.

3 Release tab washer, unscrew three set

screws and remove

flywheel assembly from the

crankshaft.

4

Drill or cut ring gear and prise from flywheel.

5 Heat

new

ring gear evenly and

fit

to

flywheel.

6 Using a 0·038mm (0·0015in) feeler gauge

check that no

clearance exists between ring

gear and

flywheel over the complete

circumference.

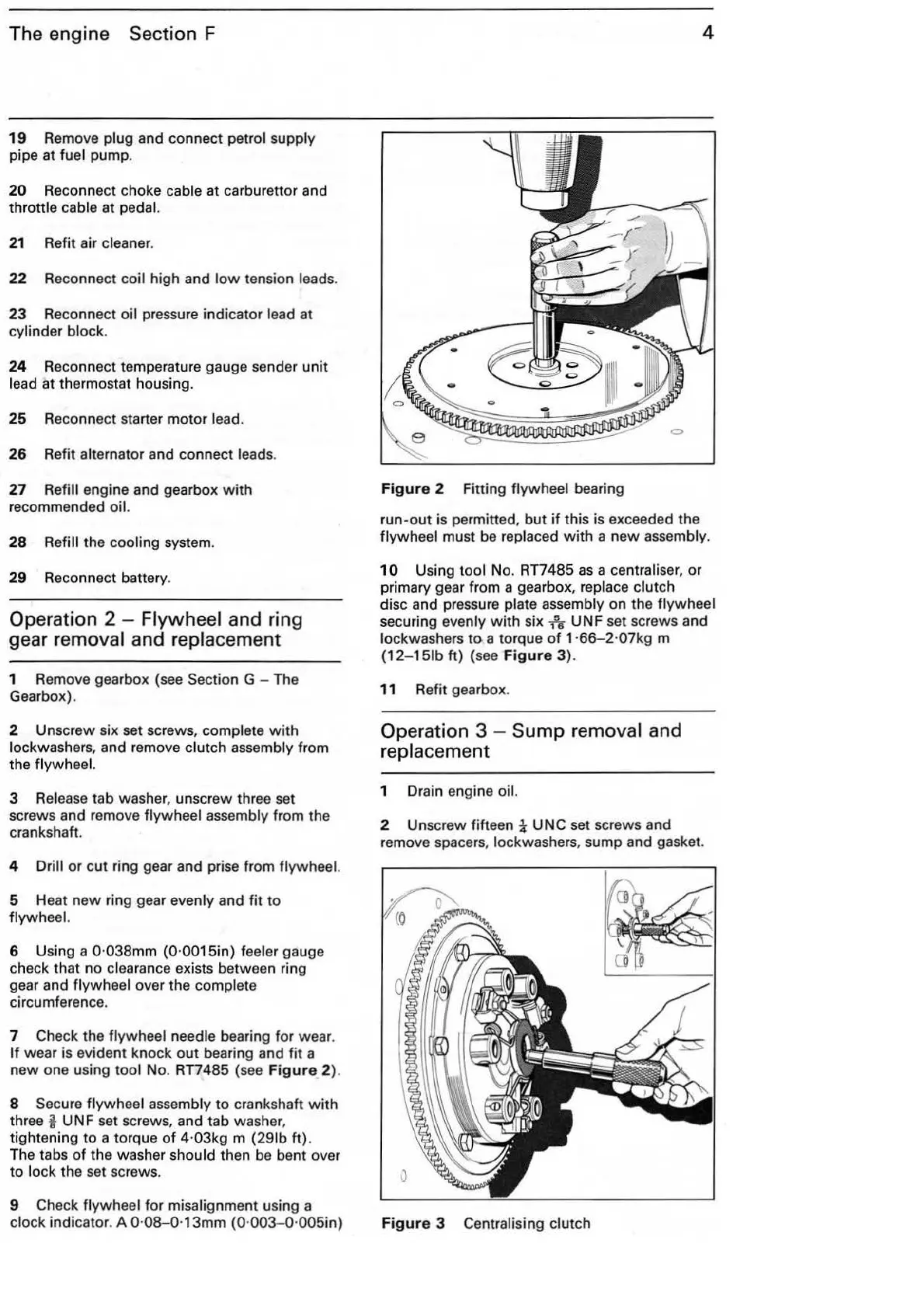

7 Check the

flywheel needle bearing for wear.

If wear is evident knock

out

bearing and fit a

new one using

tool No. RT7485 (see

Figure

2).

8

Secure flywheel assembly

to

crankshaft

with

three i UNF set screws, and tab washer,

tightening

to

a torque

of

4·03kg m

(291b

ft).

The tabs

of

the washer should then be bent over

to

lock the set screws.

9 Check

flywheel for misalignment using a

clock indicator. A 0·

08-0·13mm

(0·

003-0

·005in)

4

Figure

2 Fitting flywheel bearing

run-out is permitted,

but

if

this is exceeded the

flywheel must be replaced

with

a new assembly.

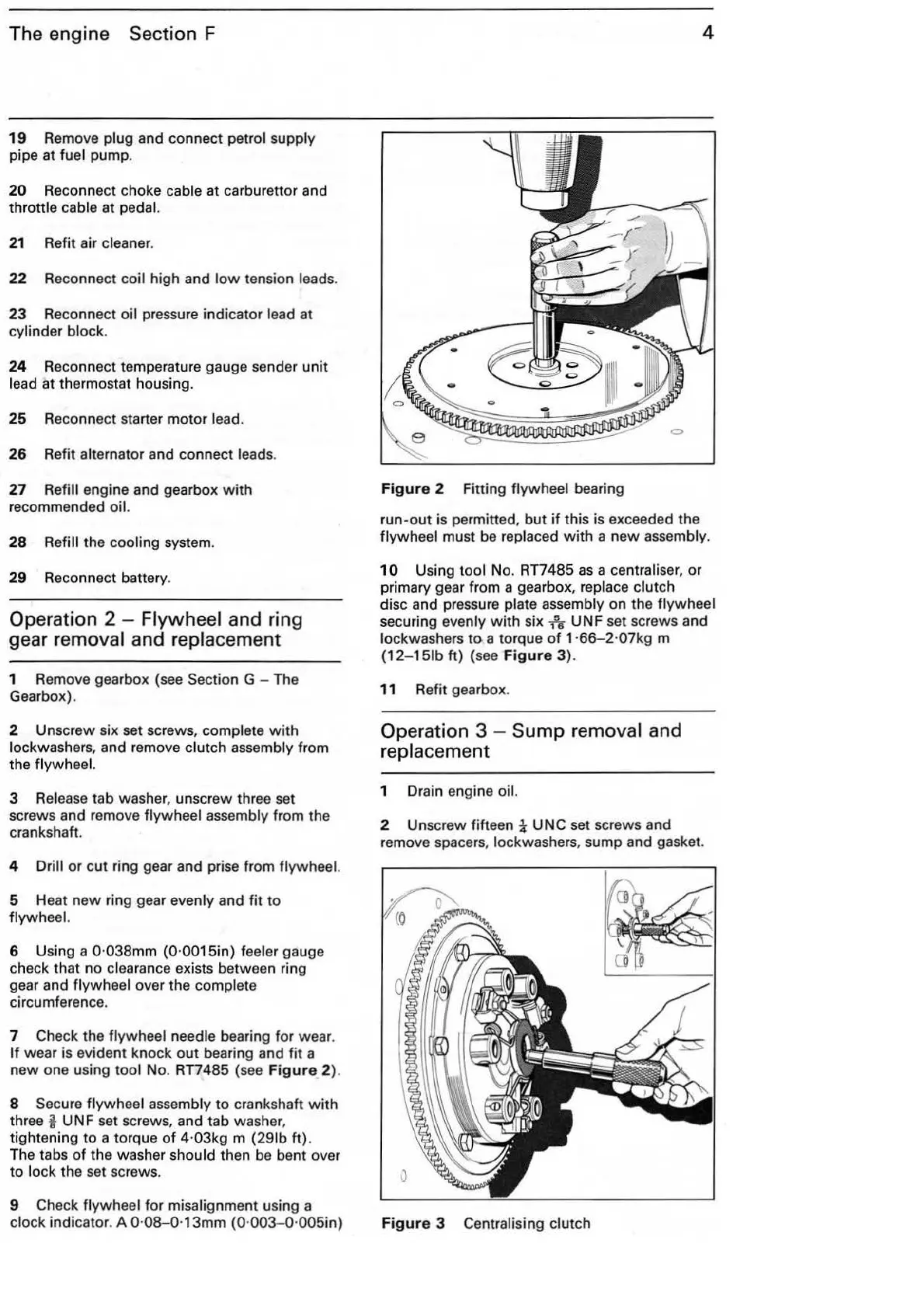

10

Using tool No. RT7485

as

a centrali

ser,

or

primary gear from a gearbox,

replace clutch

disc and pressure plate assembly on the flywheel

securing evenly

with

six

1

5

6

UNF set screws and

lockwashers

to

a torque

of

1·66-2

·07kg m

(12-151b

ft)

(see

Figure

3)

.

11 Refit gearbox.

Operation 3 - Sump removal and

replacement

1 Drain engine oil.

2 Unscrew fifteen 1

UNC

set screws and

remove spacers,

lockwashers, sump and gasket.

Figure

3 Centralising clutch

Loading...

Loading...