The engine Section F

3 Clean the sump and its seating on the

cylinder block face.

4 To

eliminate possible oil leakage the

two

cent

re

front and rear fixing screw threads should

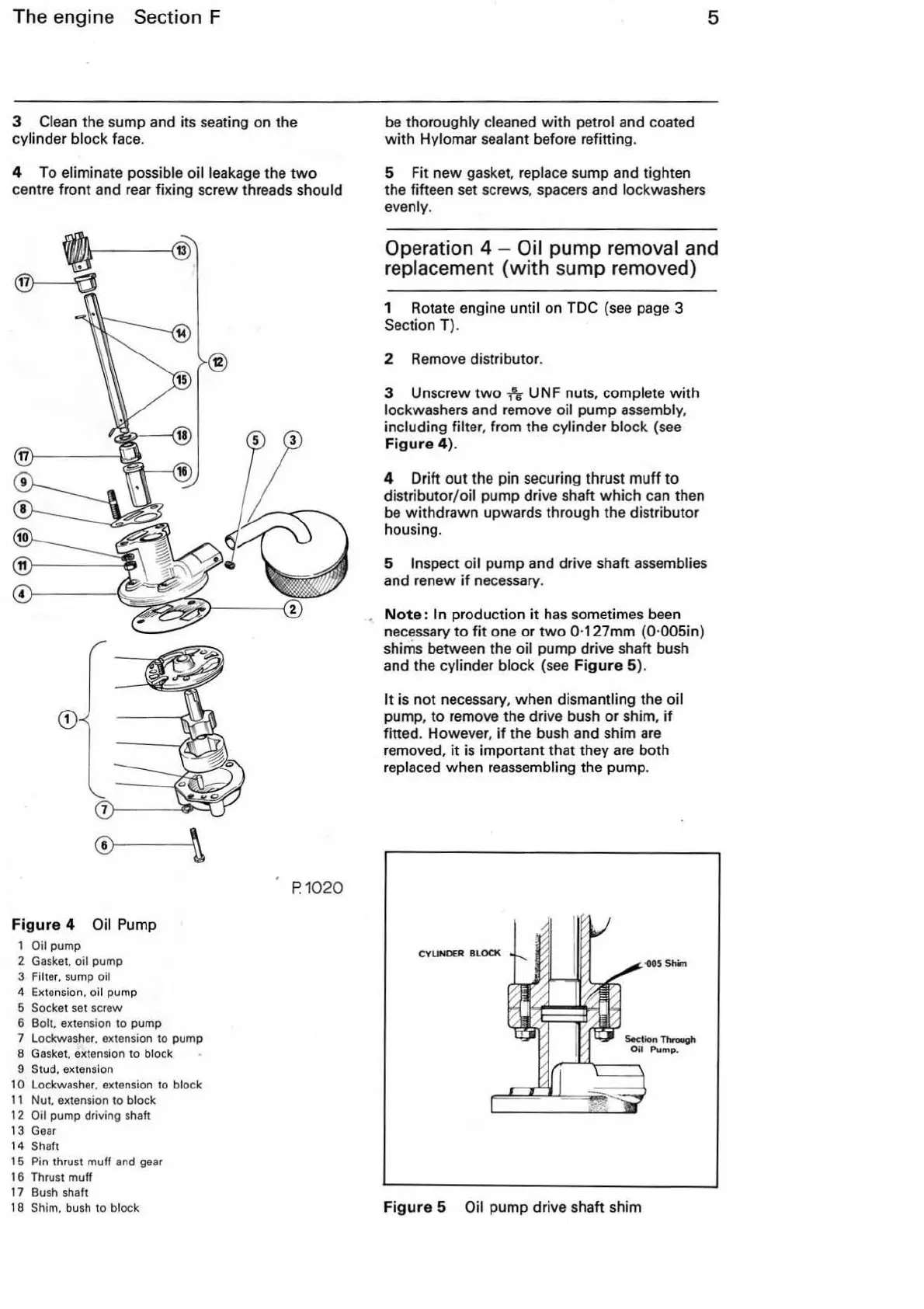

Figure

4 Oil Pump

1 Oil pump

2 Gasket,

oil pump

3 Filter, sump oil

4 Extension, oil pump

5 Socket set screw

6 Bolt. extension

to

pump

7 Lockwasher,

ex

tension to pump

8

Gaske

t.

ex

tension to bl

oc

k

9 Stud. extension

1 0 Lockwasher, extension to block

11

Nut. extension to block

12 Oil pump driving shaft

13

Gear

14

Sha

ft

1 5 Pin thrust mu

ff

and gear

16

Thrust muff

17 Bush

shaft

18 Shim. bush to block

P.1020

be thoroughly cleaned

with

petrol and coated

with

Hylomar sealant before refitting.

5 Fit

new

gasket, replace sump and tighten

the fifteen set screws, spacers and

lo

ckwashers

evenly.

5

Operation 4 - Oil pump removal and

replacement

(with

sump removed)

1 Rotate engine until on TDC (see page 3

Section T).

2 Remove distributor.

3 Unscrew

two

-h UNF nuts, complete

with

lo

ckwashers and remove oil pump assembly,

including filter,

from the cylinder block (

see

Figure

4).

4 Drift

out

the pin securing thrust

muff

to

distributor/ oil pump drive shaft

whi

ch can then

be

withdrawn

upwards through the distributor

housing.

5

Inspect oil pump and drive shaft assemblies

and renew

if

necessary .

•

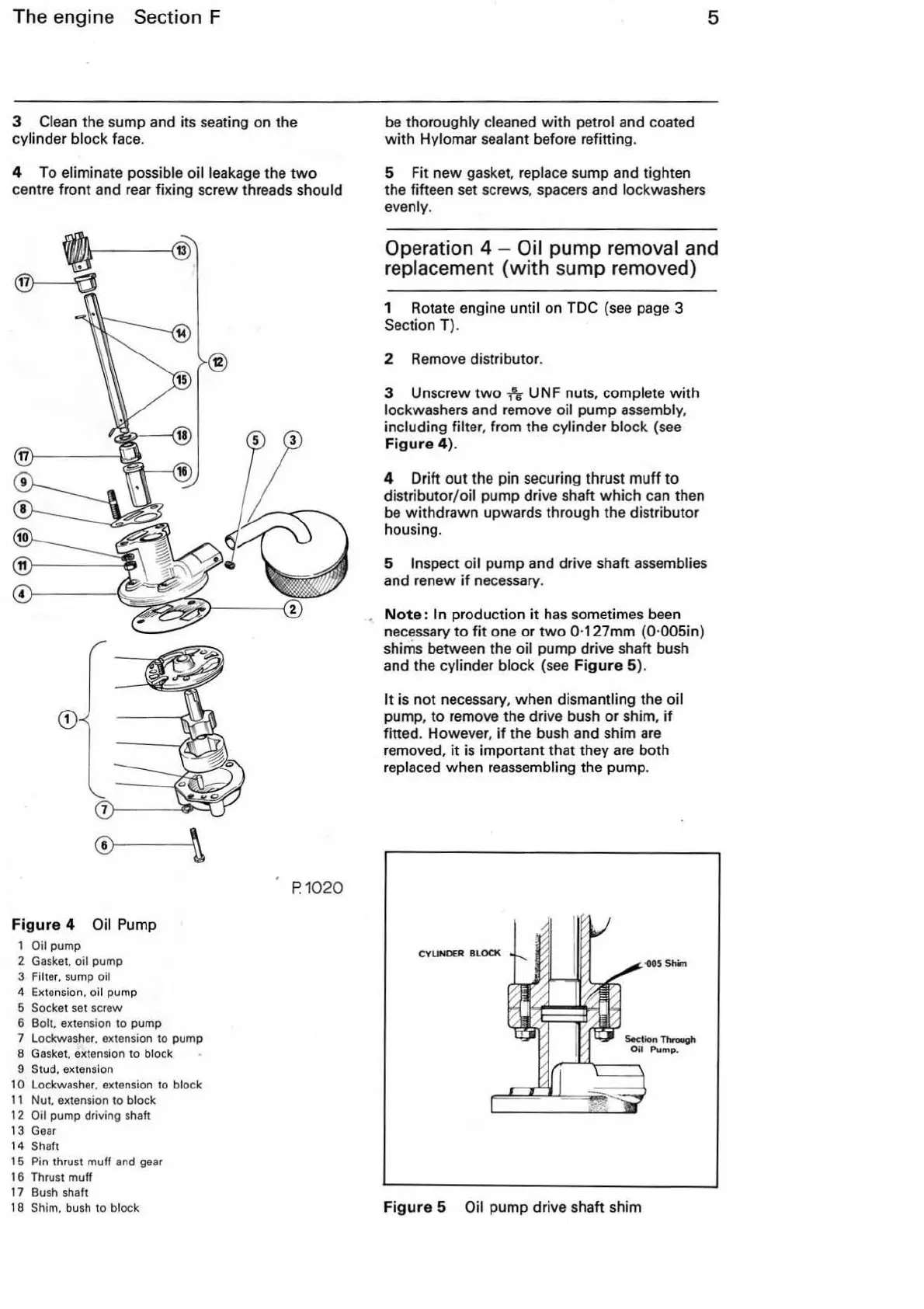

Note:

In production it has sometimes been

necessary

to

fit

one

or

two

0·127mm (0·005in)

shims between the oil pump

dr

i

ve

shaft bush

and the

cylinder block (see

Figure

5

).

It

is

not

necessary, when dismantling the oil

pump,

to

remove the

dr

i

ve

bush

or

shim,

if

fitted.

Howe

v

er

,

if

the bush and shim

are

removed,

it

is important that they are both

replaced when reassembling the pump.

Figure

5 Oil pump drive shaft shim

Loading...

Loading...