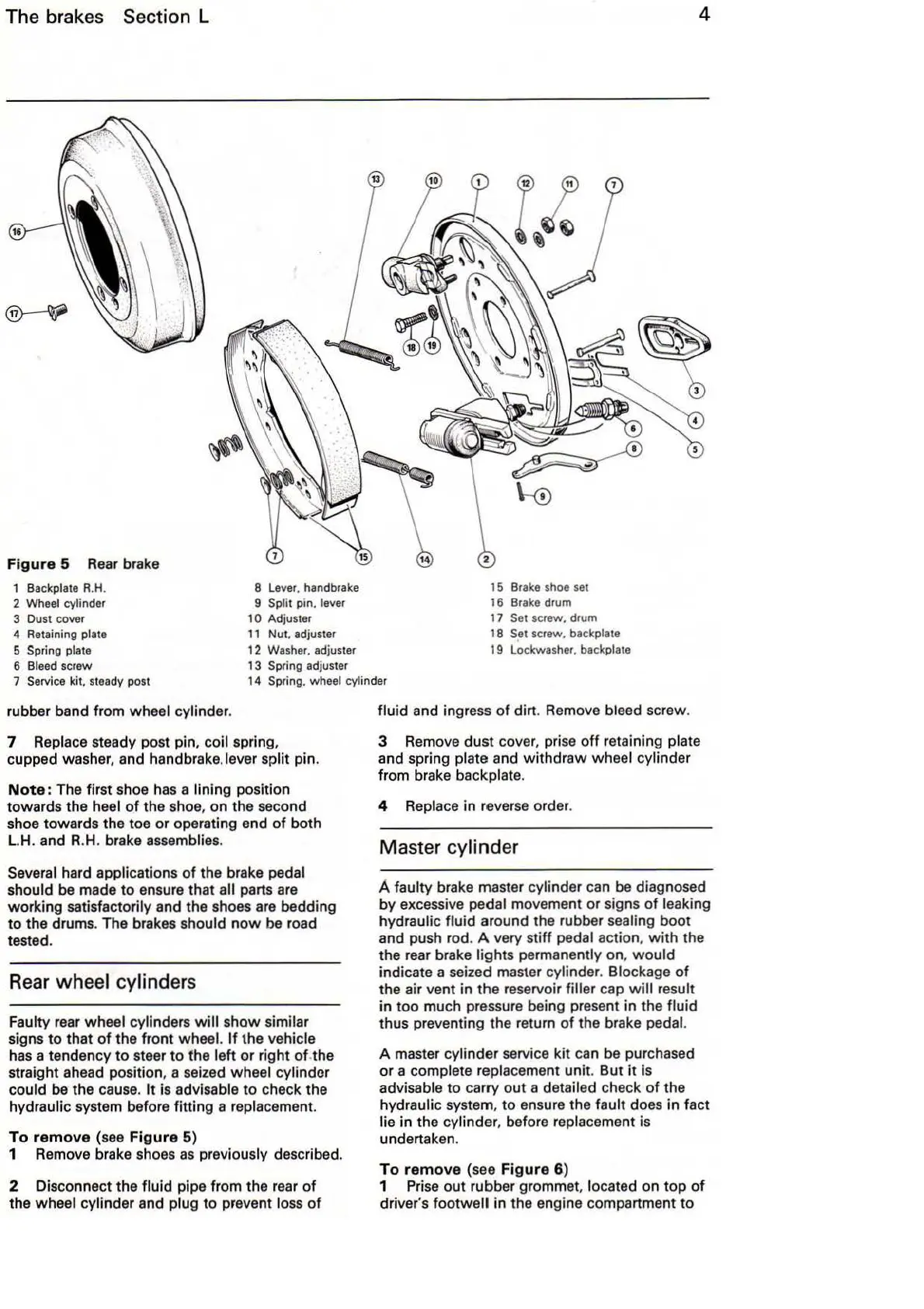

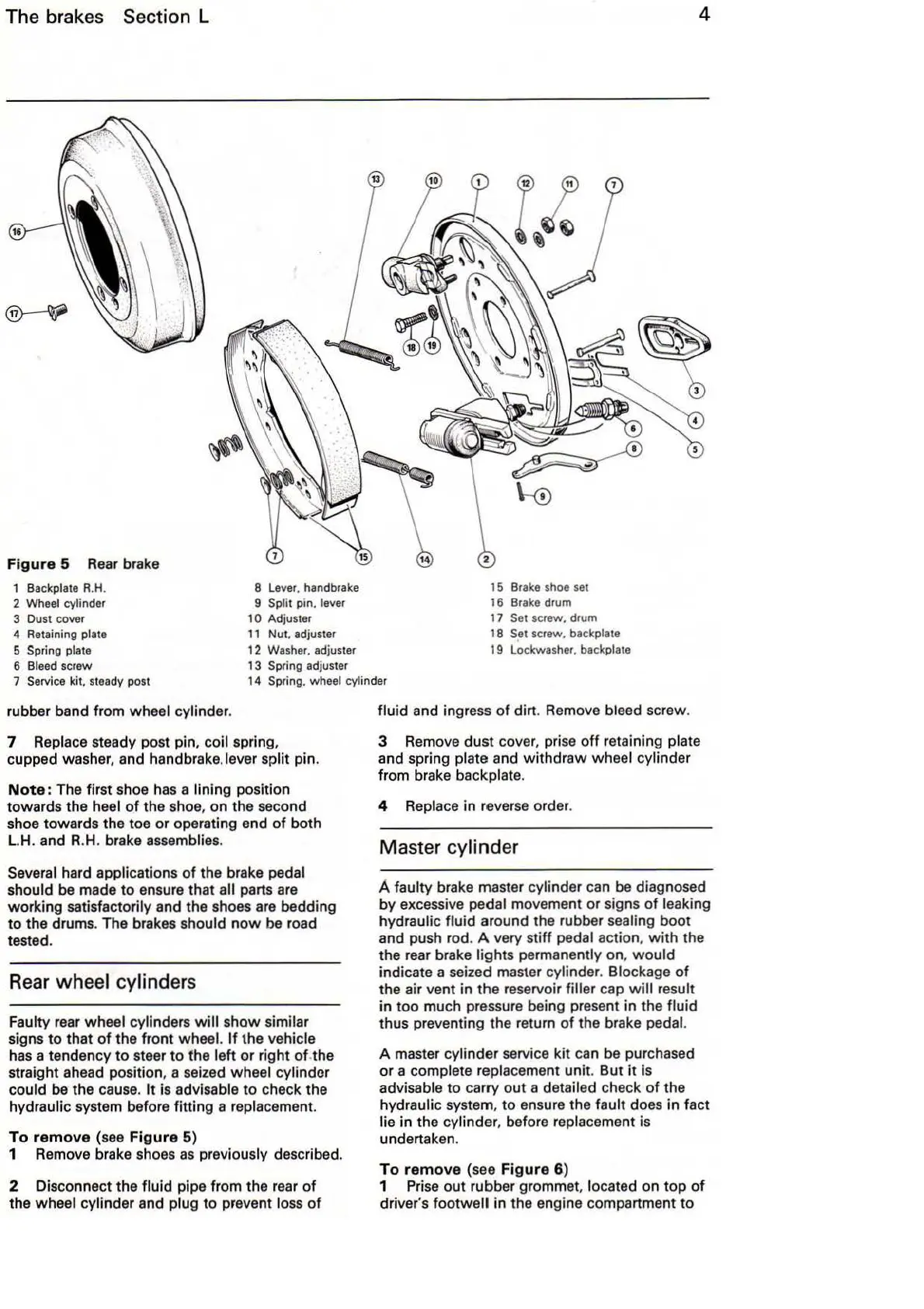

The brakes Section L

Figure

5 R

ea

r brake

1 Backplate

R.H

.

2 Wheel cylinder

3

Oust cover

4 Retaining plate

5

Spring plate

6 Bleed screw

8 Lever. handbrake

9 Split pin. lever

10

Adjuster

11

Nut. adjuster

12 Washer. adjuster

13 Spring adjuster

15 Brake shoe set

16

Brake

drum

17

Set screw. drum

18 Set screw. backplate

19 Lockwasher. backplate

4

7 Service kit. steady post

14 Spring. wheel cylinder

rubber band from wheel cylinder.

7 Replace steady post pin.

coil spring,

cupped washer, and handbrake.lever

sp

lit pin.

Note:

The

fir

st shoe

has

a lining position

towards the heel

of

the shoe, on the second

shoe towards the toe or operating end of both

L.H.

and R.H. brake

asse

mbli

es.

Several hard applications

of

the brake pedal

should

be

made

to

ensure that all parts

are

working satisfactorily and the shoes

are

bedding

to

the drums. The

bra

kes

sho

ul

d n

ow

be

road

te

ste

d.

Rear

wheel cylinders

Faulty rear wheel cylind

ers

will

show similar

signs

to

that

of

the front wheel.

If

the

ve

hi

c

le

has

a tendency

to

steer

to

the left or right

of

.the

straight ahead position, a seized wheel cylinder

could

be

the

ca

u

se.

It

is advisable

to

check the

hydraulic system before fitting a replacement.

To

remove

(

see

Figure

5)

1 Remove brake shoes

as

previously described.

2 Disconnect the fluid pipe from the r

ea

r

of

the wheel cylinder and plug

to

prevent lo

ss

of

fluid and ingress

of

dirt.

Re

move bleed

sc

rew.

3 Remove dust

cover, pr

ise

off

retaining plate

and spring plate and withdraw wheel cylinder

from brake backplate.

4

Repl

ace

in reve

rse

order.

Master cylinder

A faul

ty

brake master cylinder can

be

diagnosed

by excessive

pedal movement or signs of leaking

hydraulic

fluid around the rubber sealing boot

and push rod. A very stiff

pedal action.

with

the

the

rea

r brake lights permanently on,

would

in

dicate a seized master cylinder. Blockage

of

the air vent in

the

reservoir filler cap

will

result

in too much pressure being present in the

fluid

thus preventing the return

of

the brake pedal.

A

ma

ster cylinder service kit can

be

purchased

or a complete replacement unit. But

it

is

advisable

to

ca

rry

out

a detailed check

of

the

hydraulic system. to ensure the

fault does

in

fact

lie in the cylinder. before replacement

is

undertak

en.

To

remove

(see

Figure

6)

1 Prise

out

rubber grommet, located on top

of

driver's footwall in the engine compartment

to

Loading...

Loading...