Fu

el system Section P

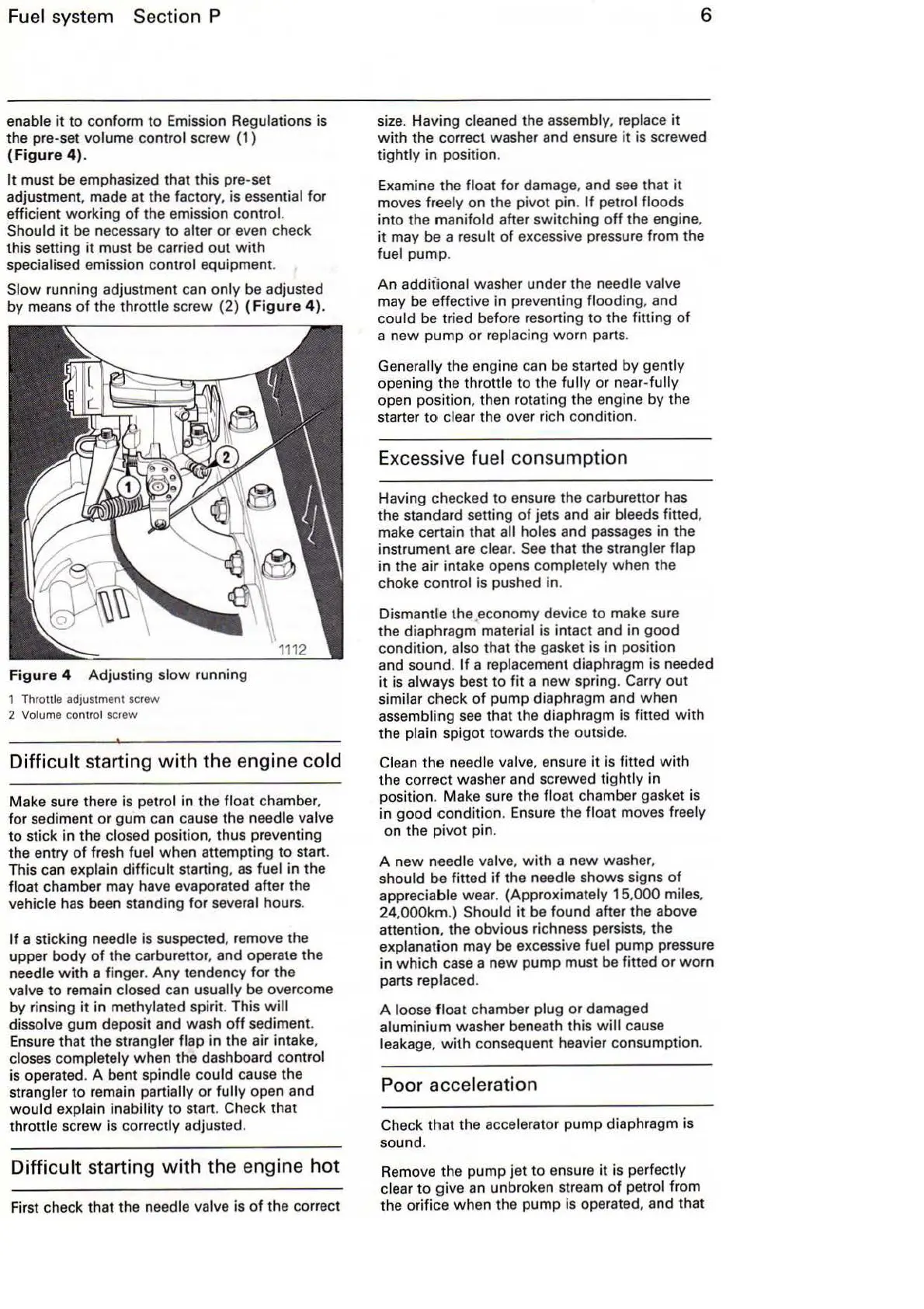

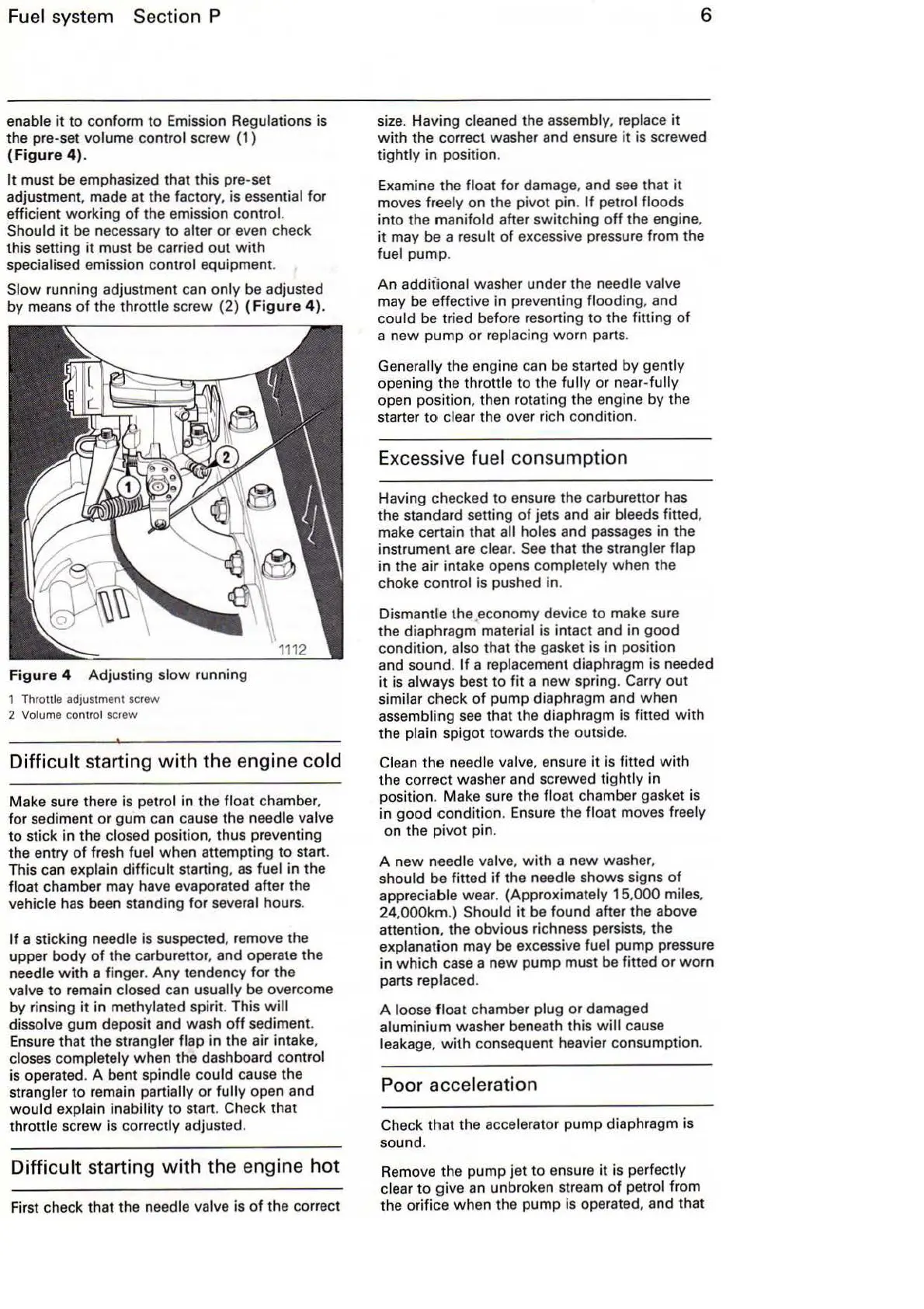

enable

it

to conform

to

Emission Regulations is

the pre-set

vo

lume control screw (1)

(Fig

ur

e 4).

It must

be

emphasized that this pre-set

adjustment, made at the factory, is

essential for

efficient working

of

the emission control.

Should

it

be

necessary to alter

or

even check

this setting

it

must be carried

out

with

specialised emission control equipment.

Slow

running adjustment can only

be

adjusted

by means

of

the throttle screw (2) (Fi

gu

re 4).

Fig

ur

e 4 Adjusting

slow

running

1 Throttle adjus

tm

ent screw

2

Volume control screw

Diffic

ult

starting with the engine cold

Make sure there is petrol in the float chamber.

fo

r sediment

or

gum can cause the needle

va

lve

to stick in the closed position, thus preventing

the entry

of

fresh fuel when attempting to start.

This can

explain

difficult

starting,

as

fuel in the

float chamber may have evaporated after the

vehicle

has

been standing

for

several hours.

If a sticking needle is suspected, remove the

upper

body

of

the carburettor, and operate the

needle

with

a finger.

Any

tendency

for

the

valve

to

remain closed can usually be overcome

by rinsing it in

methylated spirit. This

will

dissolve gum deposit and wash

off

sediment.

En

sure that the strangler flap in the air intake,

closes completely when the dashboard control

is operated. A bent spindle could cause the

strangler to remain partially or

fully

open and

wou

ld explain inability to start. Check that

thr

ott

le screw is correctly adjusted.

Diffic

ult

starting w ith the engine

ho

t

First check that the needle valve is

of

the correct

6

size.

Having cleaned the assembly, replace

it

with

the correct washer and ensure

it

is screwed

tightly in position.

Examine the

float for damage, and

see

that

it

moves freely on the pivot pin.

If

petrol floods

into the manifold after switching

off

the engine,

it may be a

result

of

excessive pressure from the

fuel pump.

An

addit

ional washer under the needle valve

may

be

effective in preventing flooding, and

could be tried before resorting

to

the fitting

of

a new pump

or

replacing worn parts.

Generally the engine can

be

started by gently

opening the throttle to the

fully

or

near-

fully

open position, then rotating the engine by the

starter

to

cl

ear

the over rich condition.

Excessive fuel consump

ti

on

Having checked to ensure the carburettor has

the standard setting

of

jets and air bleeds fitted,

make certain that

all holes and passages in the

instrument

are

clear. See that the strangler flap

in the air intake opens completely

when

the

choke

control is pushed in.

Dismantle the .economy device to make sure

the diaphragm

material is intact and in

good

condition, also that the gasket is in position

and sound.

If

a replacement diaphragm is needed

it

is always best to

fit

a

new

spring. Carry

out

similar clheck

of

pump diaphragm and

when

assembling

see

that the diaphragm

is

fitted

with

the plain spigot towards the outside.

Cl

ea

n the needle valve, ensure it is fitted

with

the correct washer and screwed tightly in

position. Make sure the

float chamber gasket is

in good condition. Ensure the

float moves freely

on the

pivot

pin.

A n

ew

needle valve,

with

a new washer,

should be fitted

if

the needle shows signs

of

appreciable wear. (Approximately 15,

000

mil

es.

24,000km.) Should

it

be

found after the above

attention, the obvious richness persists, the

explanation may

be

excessive fuel pump pressure

in

which

case

a new pump must be fitted

or

worn

parts replaced.

A loose float chamber plug

or

damaged

alumini

um

washer beneath this

will

cause

leakage,

with

consequent heavier consumption.

Po

or accelera

ti

on

Check that the accelerator pump diaphragm is

sound.

Remove the pump jet to ensure

it

is perfectly

cl

ea

r to give an unbroken stream

of

petrol from

the orifice when the pump is operated, and that

Loading...

Loading...