The

rear axle

Section K

1

Description

The rear axle

is

of

the spiral bevel gear.

semi-floating

type, having a ratio

of

3·545 : 1.

A

two

piece axle case assembly houses a taper

roller bearing differential unit

with

the crown

wheel bolted

to

the casting.

The pinion sits in the centre

of

the housing

case and is supported by taper

roller bearings.

Bearing

preload in the differential assembly is

controlled by shims between the bearings and

differential casting.

The depth

of

mesh between the pinion and

crown

wheel is controlled by a spacing washer

and

ad

ditional shims

as

required.

The crown

wheel and pinion are a selected pair,

and identifying numbers are etched on both.

This condition

applies to spare parts and

production

alike. Under

no

circumstances may

an

unmatched

crown

wheel and pinion be

fitted.

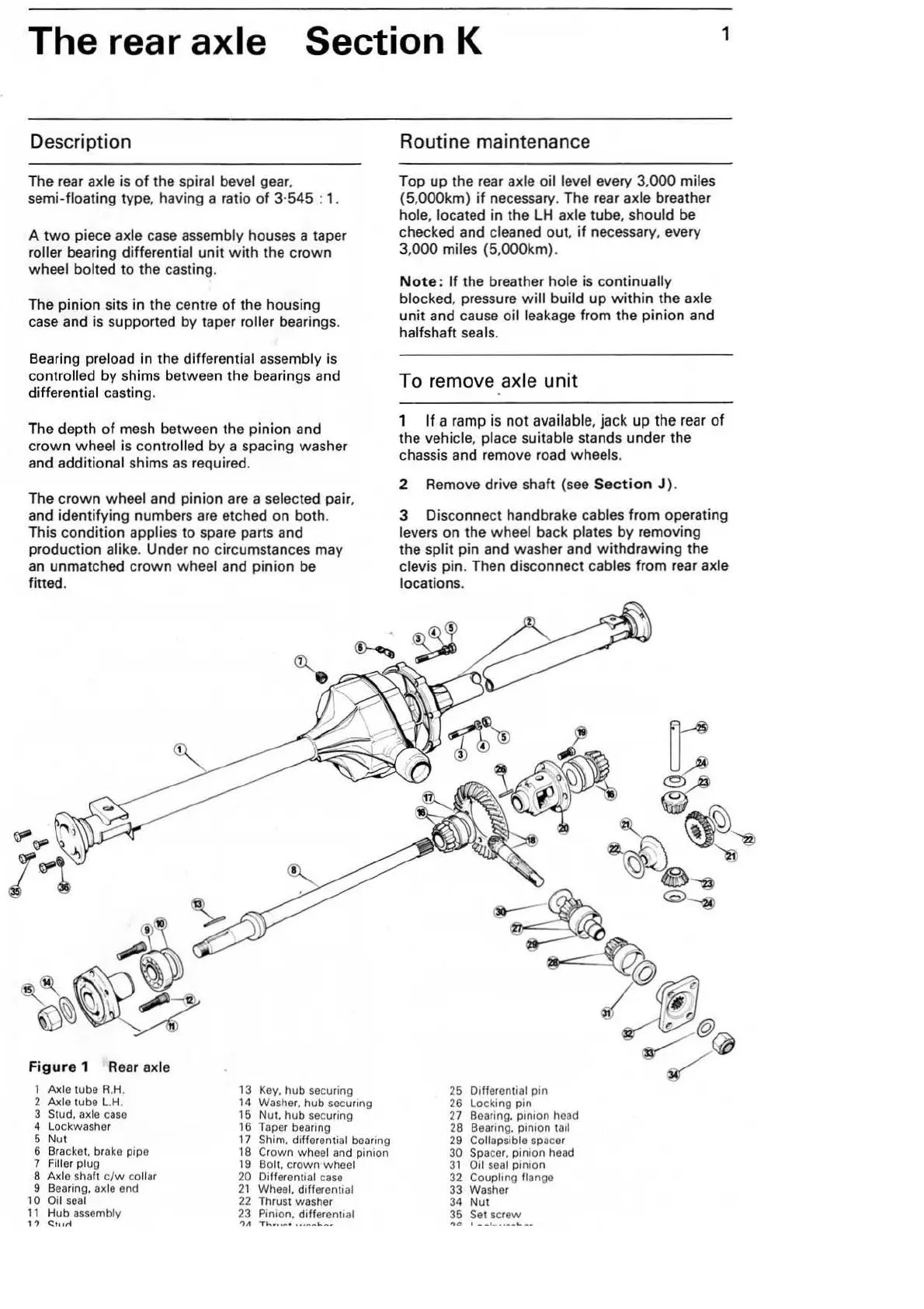

Figure

1 Rear axle

1

Axl

e tube R.H.

2

Ax

le tube

L.H

.

3 Stud.

ax

le

caso

4

Lo

c

kw

as

her

5 Nut

6

Bra

cket. brake pipe

7

Filler plug

8 Axle shaft c

/w

collar

9 Bearing.

ax

le end

10 Oil

sea

l

11

Hub assembly

1?

C:t

ll

l"f

1 3 Key. hub securing

14

Washer. hub secunng

15 Nu

t.

hub securing

16 Taper bearing

17

Shim, differential beanng

18 Crown

wh

ee

l

an

d pinion

19 Bolt, crown·wheel

20

Differential

case

21

Wheel.

d1ff

erenual

22

Thrust washer

23

Pinion. d

if

ferent•al

')A

Ts...

.......

. . ..

......

.......

..

Routine maintenance

Top

up

the rear axle oil level every 3.

000

miles

(5.000km)

if

necessary. The rear axle breather

hole, located in the LH axle tube, should

be

checked and cleaned out.

if

necessary, every

3,000 miles (5,000km).

Note

:

If

the breather hole is continually

blocked, pressure

will

build

up

within

the axle

unit

and cause

oi

l leakage from the pinion and

halfshaft seals.

To remove

ax

le

unit

1

If

a ramp is not available. jack

up

the rear

of

the vehicle. place suitable stands under the

chassis and remove road

wheels.

2 Remove drive shaft (see

Se

ctio

n J).

3 Disconnect handbrake cables from operating

levers on the wheel back plates by removing

the

split pin and washer and withdrawing the

clevis pin. Then disconnect cables from rear axle

locations.

25 Differential pin

26 Locking pin

27

Bear

ing.

p1n1on

h

ead

28 Bearing. pinion tall

29 Collapsible spacer

30 Spa

ce

r. pinion h

ead

31

O

il

seal

pinion

32

Coupling flange

33 Washer

34

Nut

35 Set screw

'"'I!!

I .,.

.,.I

_.,

..............

Loading...

Loading...