The rear axle

Se

ction K

Fig

ur

e

13

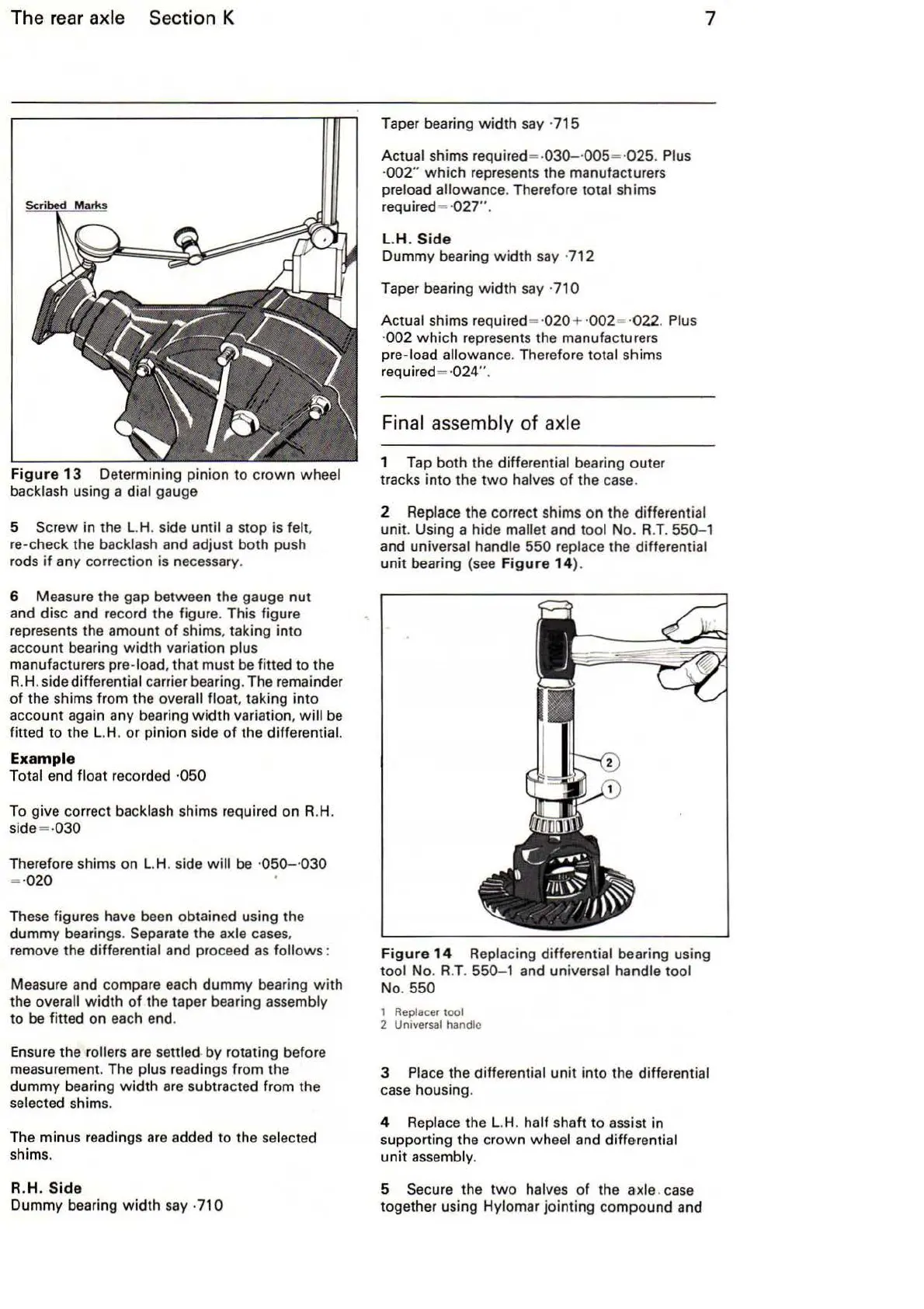

Determining pinion to

crown

wheel

backlash using a dial gauge

5 Screw in the L.H. side until a stop is felt.

re-check the

ba

cklash and adjust both push

rods

if

any correction is

ne

cessary.

6 Measure the gap between the gauge nut

and disc and record the figure. This figure

represents the amount

of

shims, taking into

account bearing

width

variation plus

manufacturers pre-load. that must be fitted to the

R.H. side differential carrier bearing. The remainder

of

the shims from the overall float. taking into

account again any bearing

width

variation.

will

be

fitted to the

L.

H. or pinion side

of

the differential.

Exa

mple

Total end float recorded ·050

To give correct backlash shims required on R.H.

side= -030

Therefore shims on

L.H

. side

will

be

·

050-

·030

= ·020

These figures have been obtained using the

dummy bearings.

Separate the axle

cases

.

remove the differential and proceed

as

follows :

Measure and compare each dummy bearing

with

the overall

width

of

the taper bearing assembly

to be fitted on each end.

Ensure the

rollers are settled by rotating before

measurement. The plus readings from the

dummy bearing

width

are

subtracted from the

selected shi

ms.

The minus readings are added to the

se

lected

sh

ims.

R.H.

Sid

e

Dummy bearing

wi

dth say ·

71

0

Taper bearing

width

say ·715

Actual shims required= ·

030-

·005= ·

025

. Plus

·002"

which

represents the manufacturers

preload allowance. Therefore

total shims

required=

·

027"

.

l.H

. S

id

e

Dummy bearing

width

say · 712

Taper bearing

width

say ·710

Actual shims required = ·

020

+ ·002= ·

022

. Plus

·002

which

represents the manufacturers

pre-load allowance. Therefore total shims

required=

·024"

.

Fi

nal assembly of axle

1 Tap both the differential bearing outer

tracks into the

two

halves

of

the

case

.

7

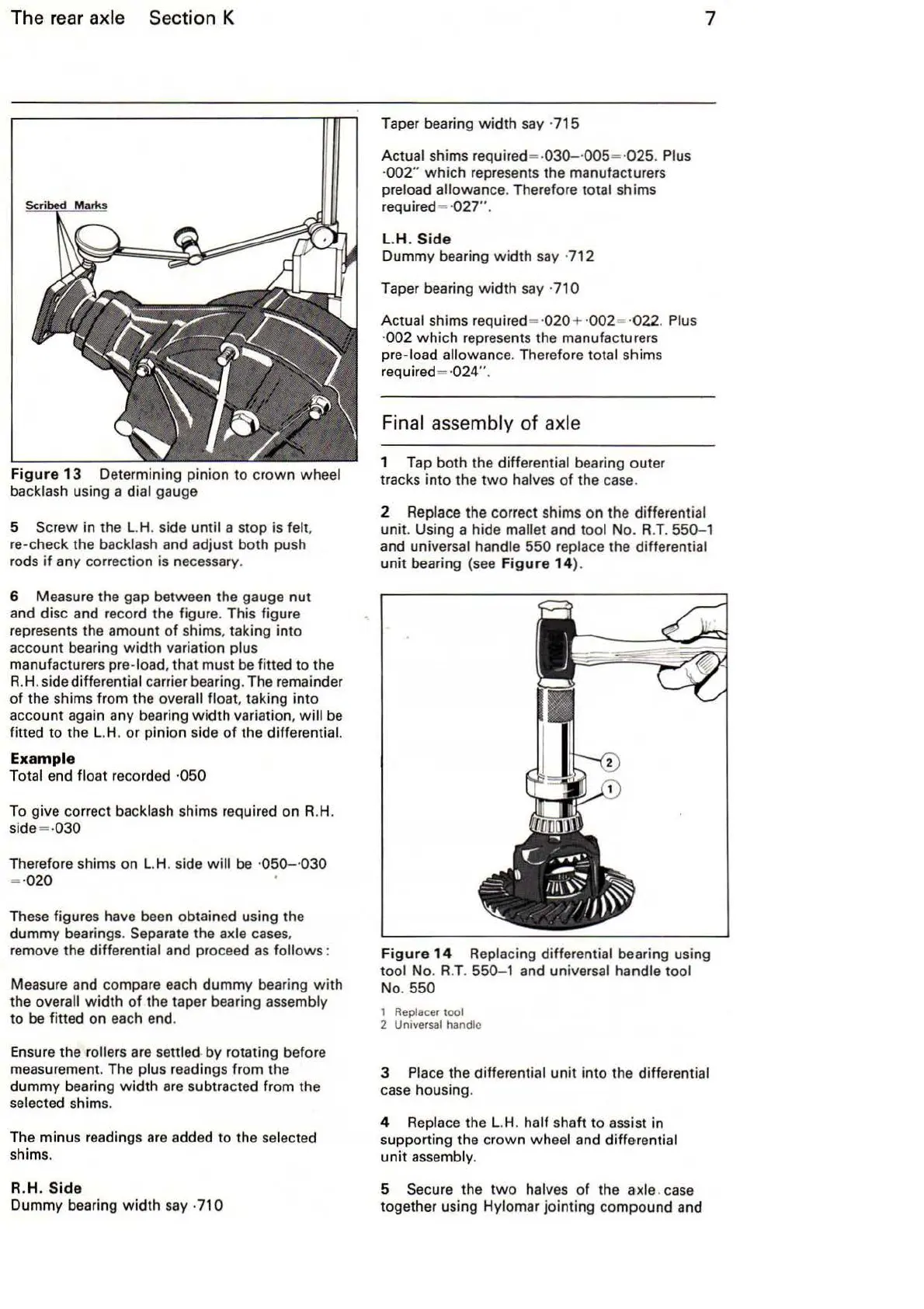

2 Replace the correct shims on the differential

unit. Using a hide

mallet and tool No. R.T. 550-1

and universal handle 550 replace the differential

unit

bearing (see F

igu

re

14

).

Figu

re

14

Replacing differential bearing using

tool No. R.T.

550- 1 and universal handle tool

No. 550

1 Replacer tool

2

Un1versal handle

3 Place the differential

unit

into

the differential

case housing.

4 Replace the L.H. half shaft to assist in

supporting the crown wheel and

dif

ferential

un

it

assembly.

5 Secure the

two

ha

lves

of

the axle.

case

together using Hylomar jointing compound and

Loading...

Loading...