The engine Section F 18

Stud removal

No. 5

va

l

ve

with

No. 4 valve fully open.

No.6

valve

with

No. 3 valve fully open.

No. 7 valve

with

No. 2 valve fully open.

No. 8 valve

with

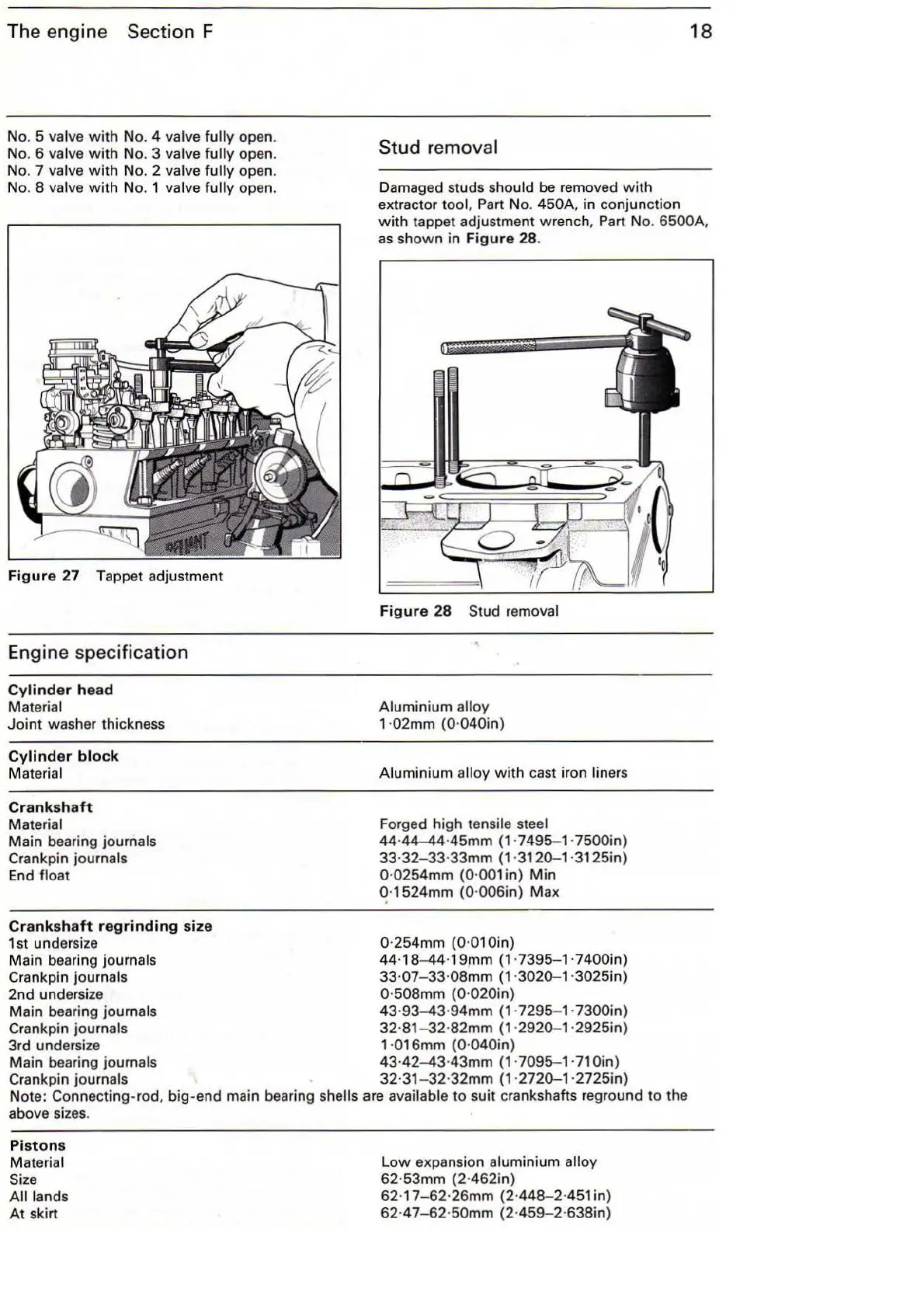

No. 1 valve fully open. Damaged studs should

be

removed with

extractor

tool, Part No. 450A. in conjunction

with

tappet adjustment wrench, Part No. 6500A,

as

shown in

Figure

28.

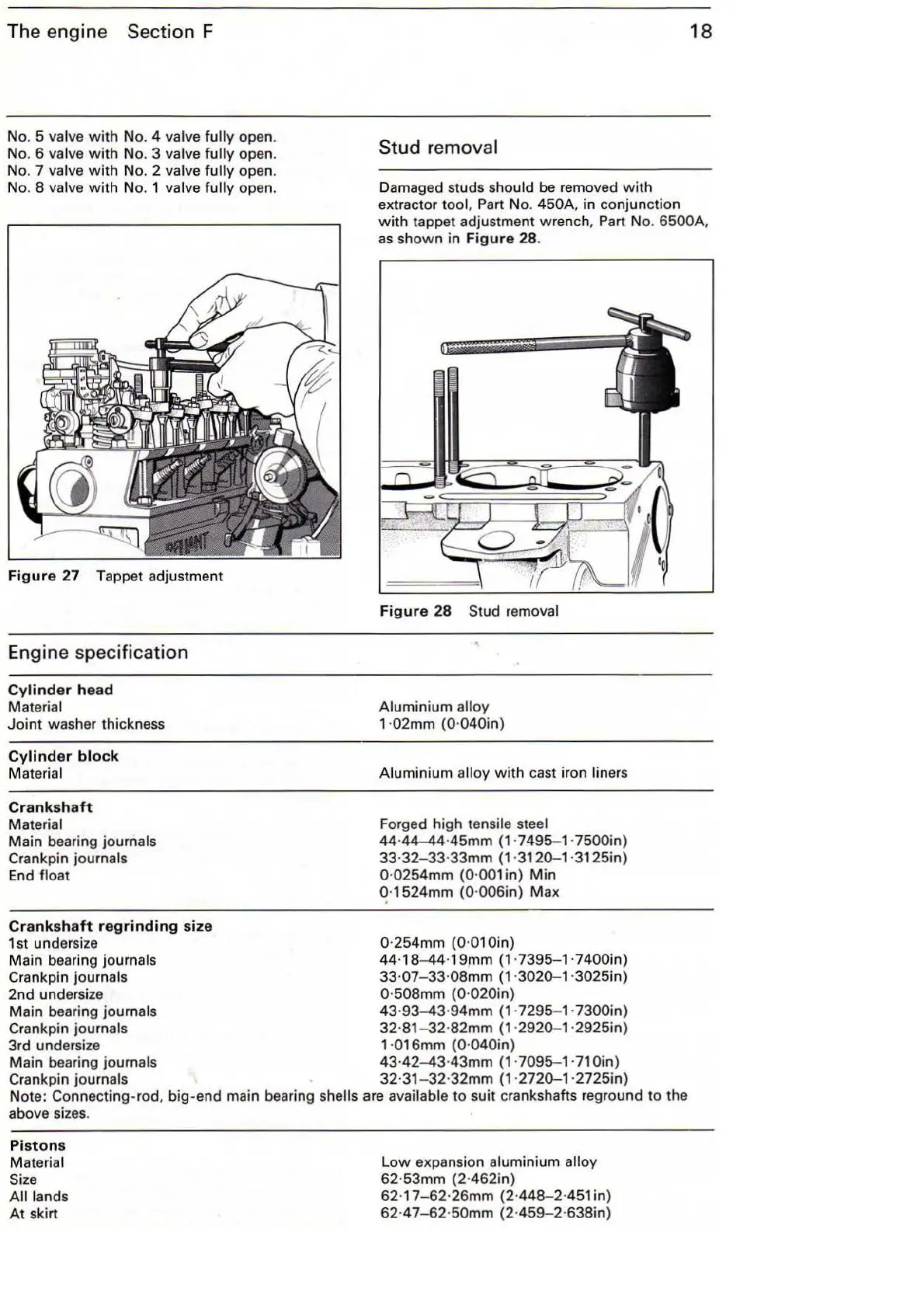

Figure

27

Tappet adjustment

Engine specifi

ca

tion

Cy

linder

head

Material

Joint

washer thickness

Cylinder

blo

ck

Material

Crank

s

haft

Material

Main bearing journals

Crankpin journals

End

float

Crank

sha

ft

regrinding

size

Figur

e

28

Stud removal

Aluminium

alloy

1 ·02mm

{0

·040in)

Aluminium alloy with cast iron liners

Forged high tensile steel

44

·

44-44

·45mm

{1

·7495-1 ·7500in)

33

·

32

-

33

·33mm {1·

3120-1·3125in

)

0·0254mm

{0

·

001

in)

Min

~

-

1524mm

{0

·006in) Max

1st undersize

0·254mm {0·

01

Oin)

Main bearing

jo

urnals

44·18-44·19

.mm

{1

·

7395-1·7400

in)

Crankpin journals 33·07- 33·08mm

{1

·3020-1 ·3025in)

2nd undersize 0·508mm

{0

·020in)

Main bearing journals 43·

93-43

·94mm

(1

·7295- 1·7300i

n)

Crankpin journals

32

·

81

- 32·82mm

{1

·2920-1·2925in)

3rd undersize 1 ·016mm {0·040in)

Main bearing journals

43

·

42-43

·43mm

(1

·7095- 1·710in)

Crankpin journals

32

·

31

-

32

·32mm

{1

·

2720-1·2725in

)

Note: Connecting-rod, big-end main bearing shells are available to suit crankshafts reground to the

above

si

z

es

.

Pi

stons

Material

Si

ze

All lands

At

skirt

Low

expansion aluminium alloy

62·53mm (2·462in)

62·17- 62·26mm {2·448-2-451

in)

62

·

47

- 62·50mm {2·459- 2·638in)

Loading...

Loading...