Robin

850

Workshop

Manual

Supplement

The engine

23

Remove the four nuts securing the rocker

shaft. Remove the rocker shaft

assembly.

24

Remove the eight push rods. carefully

noting their correct order for subsequent

replacement.

2&

Disconnect the downpipe from the

exhaust

manifold. secured by

two

nuts.

28

Remove the three nuts and lockwashers

securing the cylinder head

to

the cylinder

block

on the spark plug side.

27

Remove the three bolts

sec

uring the

thermostat housing to the

cylinder head.

28

Remove the

nut

securing the dipstick

support bracket and earth

lead to the cylinder

head.

29

Remove the

12

nuts and washers

securing the

cylinder head

to

the cylinder

block

studs.

30

Remove by-pass hose from thermostat

housing. fitted on

ea

rly vehicles only.

3~

~arefully

lift

the cylinder head complete

w1th

mlet and exhaust manifolds from the

cylinder block. Replace in reverse order. after

cleaning the cylinder head and block faces

and fitting a new gasket.

To ensure a good

seal

when replacing the

cylinder head. smear gr

ease

around the metal

edges

of

the gasket bore eyelets.

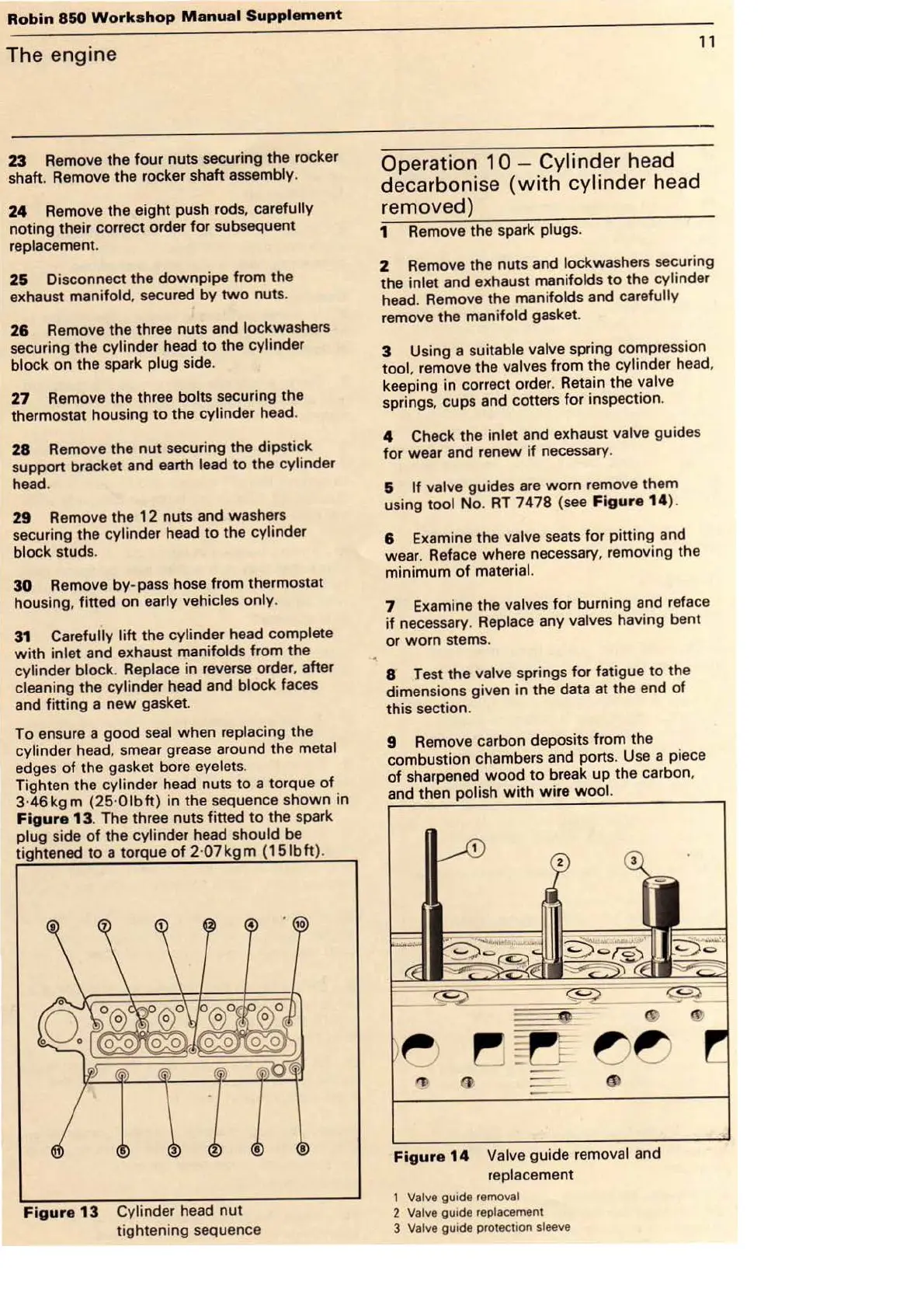

Tighten the cylinder head nuts to a torque

of

3·_46kgm (25·01bft) in the sequence shown in

F1gure

13

. The three

nut

s fitted

to

the spark

plug side

of

the cylinder head should be

tightened

to

a torque of 2·

07kgm

(151

bft)

.

Figure

13

Cylinder head

nut

tightening sequence

11

Operation 1 0 - Cylind

er

head

decarbonise (

with

cylinder h

ea

d

removed)

1 Remove the spark plugs.

2

~amove

the nuts and lockwashers securing

the

mlet and exhaust manifolds

to

the cylind

er

head. Remove the manifolds and carefully

remove the manifold gasket.

3 U

si

ng a suitable valve spring compression

tool. remove the valves from the cylinder head.

keeping in correct order. Retain the

valve

springs. cups and cotters f

or

inspection.

4 Check the inlet and exhaust valve guides

fo

r wear and renew if

ne

cessary.

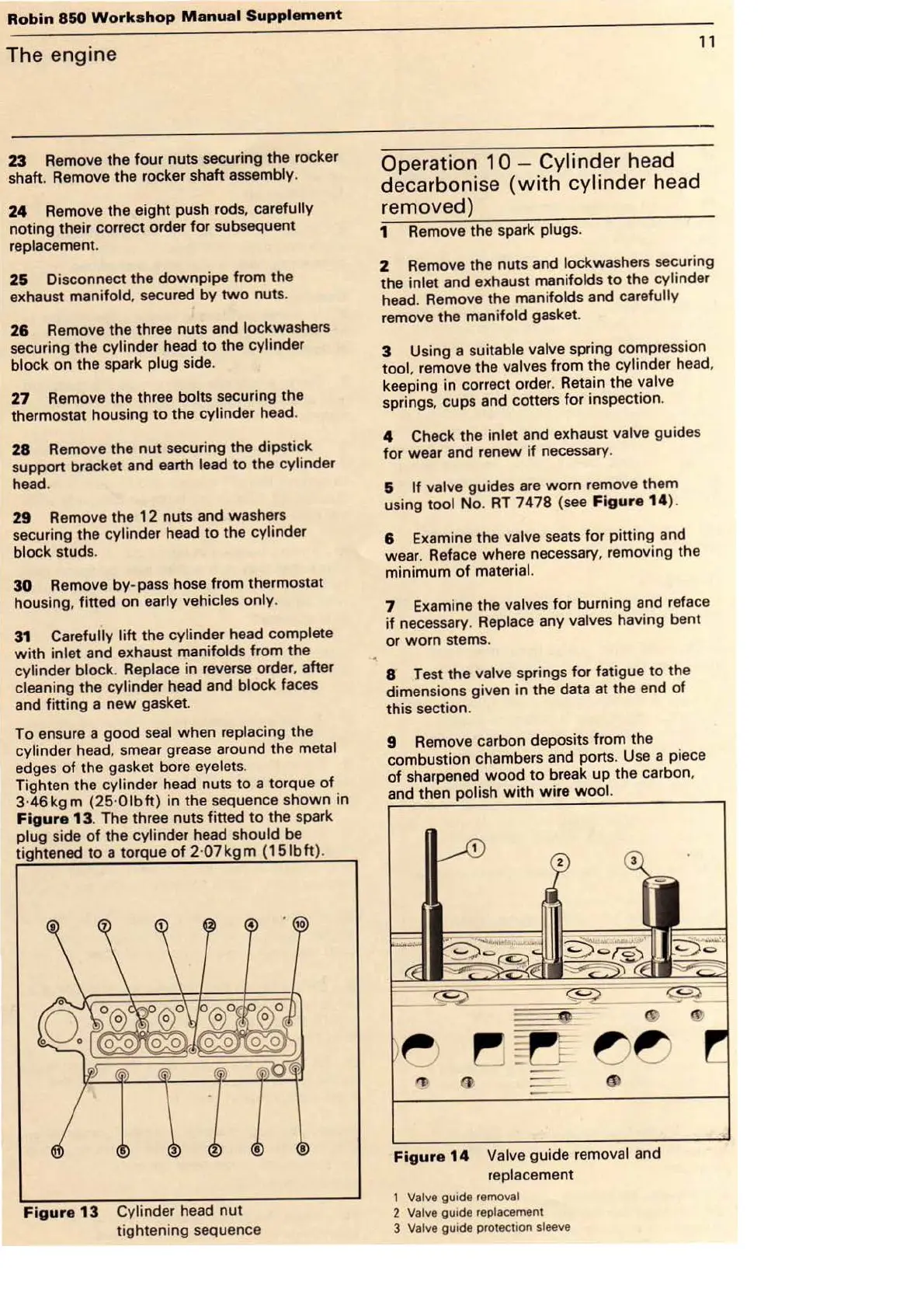

&

If

valve guides are worn remove them

using

tool No.

RT

7478 (s

ee

Figure

14

).

8 Examine the valve

sea

ts for pitting and

wear. Reface where necessary. removing the

minimum

of

material.

7 Examine the valves f

or

burning and reface

if

necessary. Replace any valves having bent

or

worn

st

ems.

8 Test the valve springs for fatigue to

th

e

dimensio

ns

given in the data at the end

of

this section.

9 Remove carbon deposits from the

combustion chambers and ports. Use a piece

of

sha

rpened

wood

to

break up the carbon.

and then

polish

wi

th

wire

woo

l.

Figure

14

Valve guide removal and

replacement

1 Valve guide removal

2 Valve

guide

replacement

3 Valve

gu1de

protection sleeve

Loading...

Loading...