The driveshaft

Section

J

1

Description

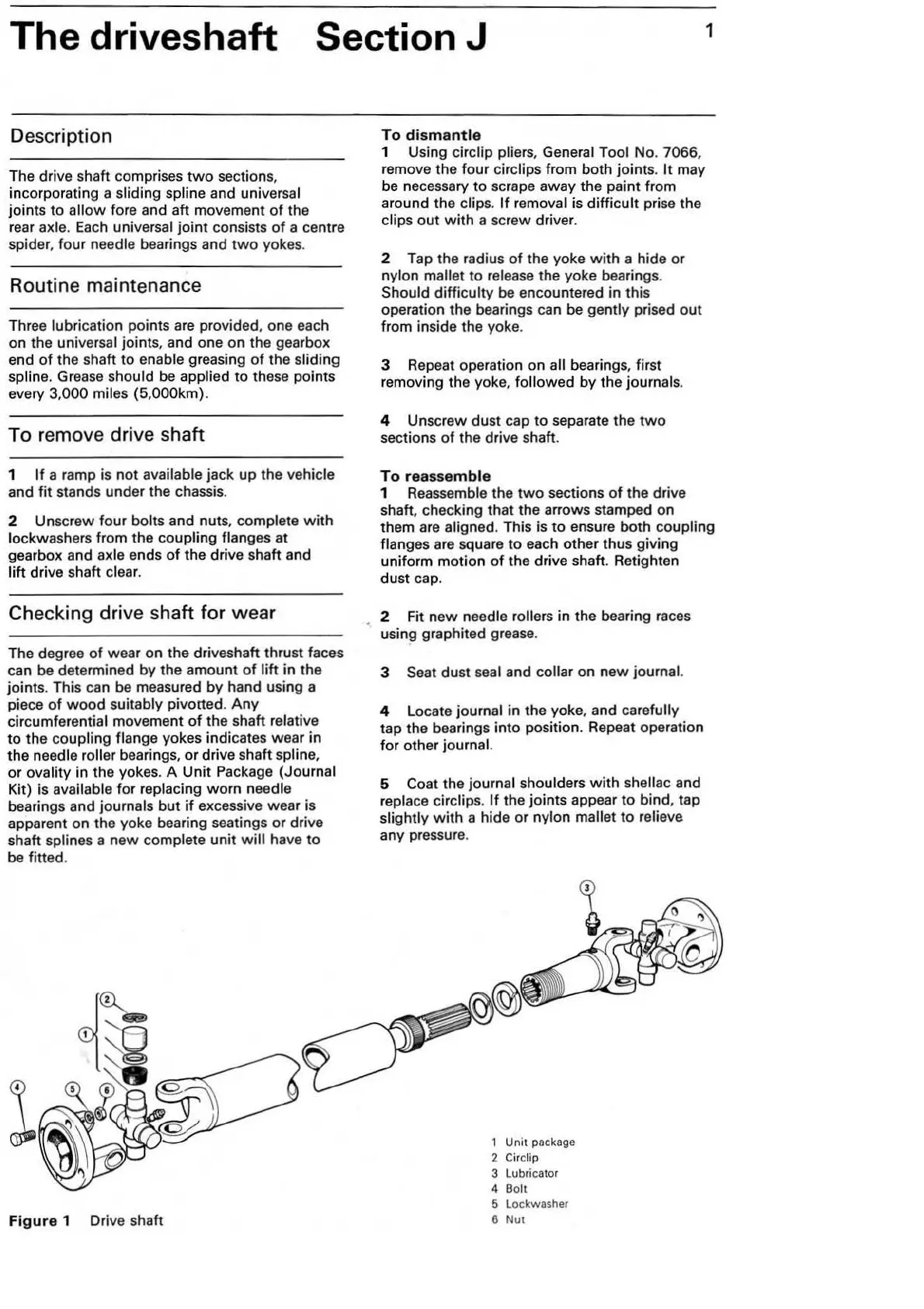

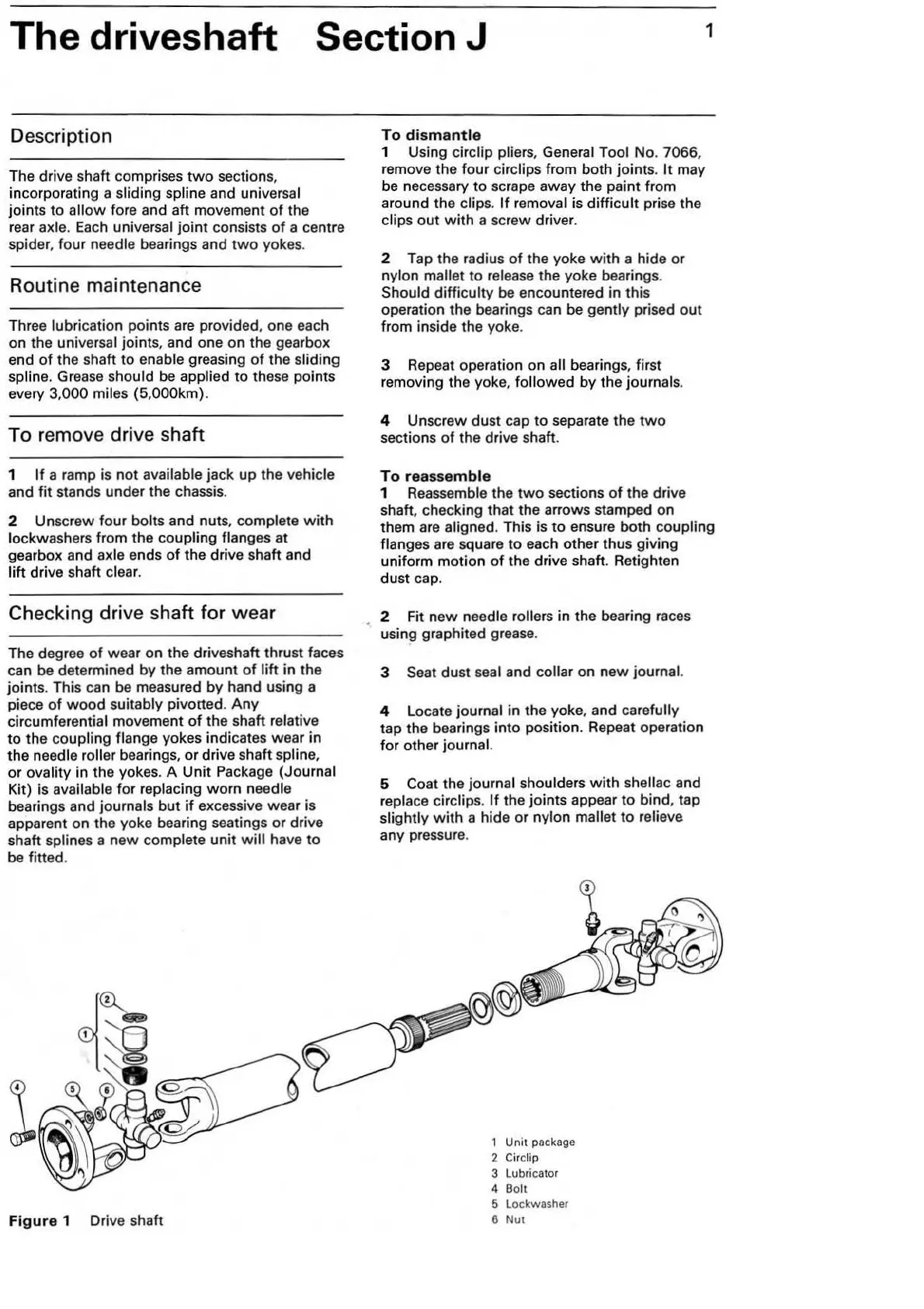

The drive shaft comprises

two

sections,

incorporating a

sliding spline and universal

joints

to

allow

fore and aft movement

of

the

rear

axle.

Each

universal

joint

consists

of

a centre

spider, four

needle bearings and

two

yokes.

Routine maintenance

Three lubrication points are provided, one each

on

the universal joints, and one on the gearbox

end

of

the shaft

to

enable greasing

of

the sliding

spline.

Grease should be applied to these points

every

3,000 miles (5,000km).

To remove drive shaft

1

If

a ramp is

not

available jack

up

the vehicle

and

fit

stands under the chassis.

2 Unscrew four

bolts and nuts, complete

with

lockwashers from the coupling flanges at

gearbox and

axle ends

of

the drive shaft and

li

ft

drive shaft cl

ear.

Checking drive shaft for wear

The degree

of

wear

on

the driveshaft thrust faces

can be determined by the amount

of

lift

in

the

joints. This can be measured by hand using a

piece

of

wood

suitably pivotted. Any

circumferential movement

of

the shaft relative

to

the coupling flange yokes indicates wear

in

the needle roller bearings, or drive shaft spline,

or ovality in the yokes. A Un

it

Package (Journal

Kit) is available for replacing worn needle

bearings and journals

but

if

excessive wear is

apparent on the yoke bearing seatings or drive

shaft

splines a

new

complete unit

will

have to

be fitted.

Figur

e 1 Drive shaft

To

dismantle

1 Using circlip plier

s,

General Tool No. 7066,

remove the four circlips from both joints.

It

may

be necessary to scrape away the paint from

around the

clips. If removal is difficult prise the

clips out

with

a screw driver.

2 Tap the radius

of

the yoke

with

a hide or

nylon mallet

to

release the yoke bearings.

Should difficulty be encountered in this

operation the bearings can be

gently prised out

from inside the yoke.

3 Repeat operation on all bearings, first

removing the yoke,

followed

by

the journals.

4 Unscrew dust cap to separate the

two

sections

of

the drive shaft.

To

re

assemb

le

1 Reassemble the

two

sections

of

the drive

shaft, checking that the arrows stamped

on

them are aligned. This is to ensure both coupling

flanges are square

to

each other thus giving

uniform motion

of

the drive shaft. Retighten

dust cap.

2 Fit

new

needle rollers in the bearing races

using graphited grease.

3 Seat dust seal and collar on

new

journal.

4 Locate journal in the yoke, and carefully

tap the bearings into position. Repeat operation

for other

journal.

5 Coat the journal shoulders

with

shellac and

replace circlips.

If

the joints appear to bind, tap

slightly

with

a hide or nylon mallet to relieve

any pressure.

1 Unit package

2 Circlip

3 Lubricator

4 Bolt

5 Lockwasher

6 Nut

Loading...

Loading...