IMAGE TRANSFER AND PAPER SEPARATION 20 June 2005

6-84

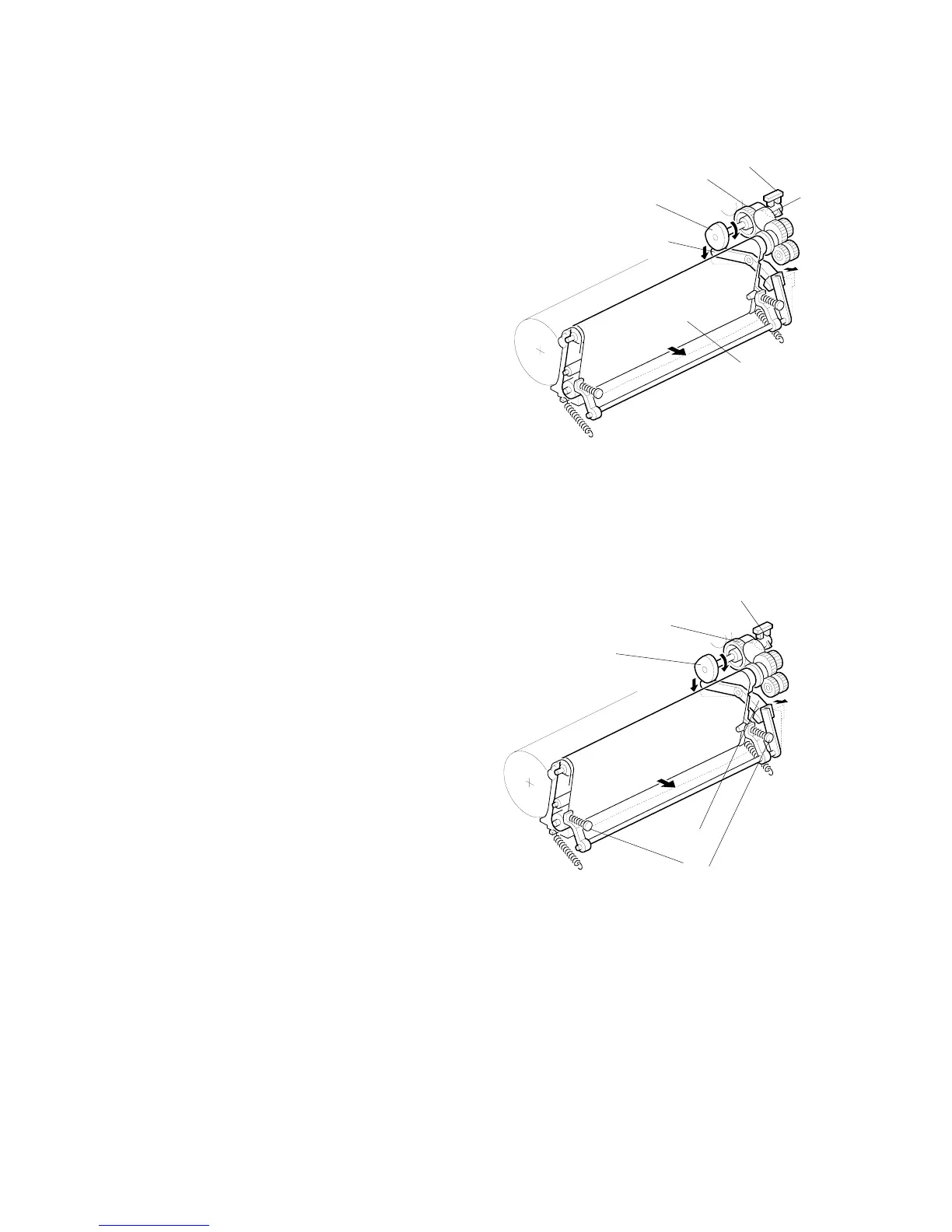

6.14.2 BELT DRIVE MECHANISM

After the main motor switches on during

copying, the transfer belt contact clutch [A]

switches on after a specified interval and

the cam [F] makes a half-turn to raise the

contact lever [E] and bring the transfer belt

[D] into contact with the drum.

The actuator [C], on the same axis as the

cam, and the transfer belt position sensor

[B] detect whether the drum and transfer

belt are in contact.

When the main motor is off, or when the ID

sensor pattern is being measured, the

transfer belt unit separates from the drum.

The ID sensor pattern must not be transferred to the belt. Also, the transfer belt

and drum must not remain in contact for too long, to prevent contamination of the

drum with oil or other foreign material from the transfer belt.

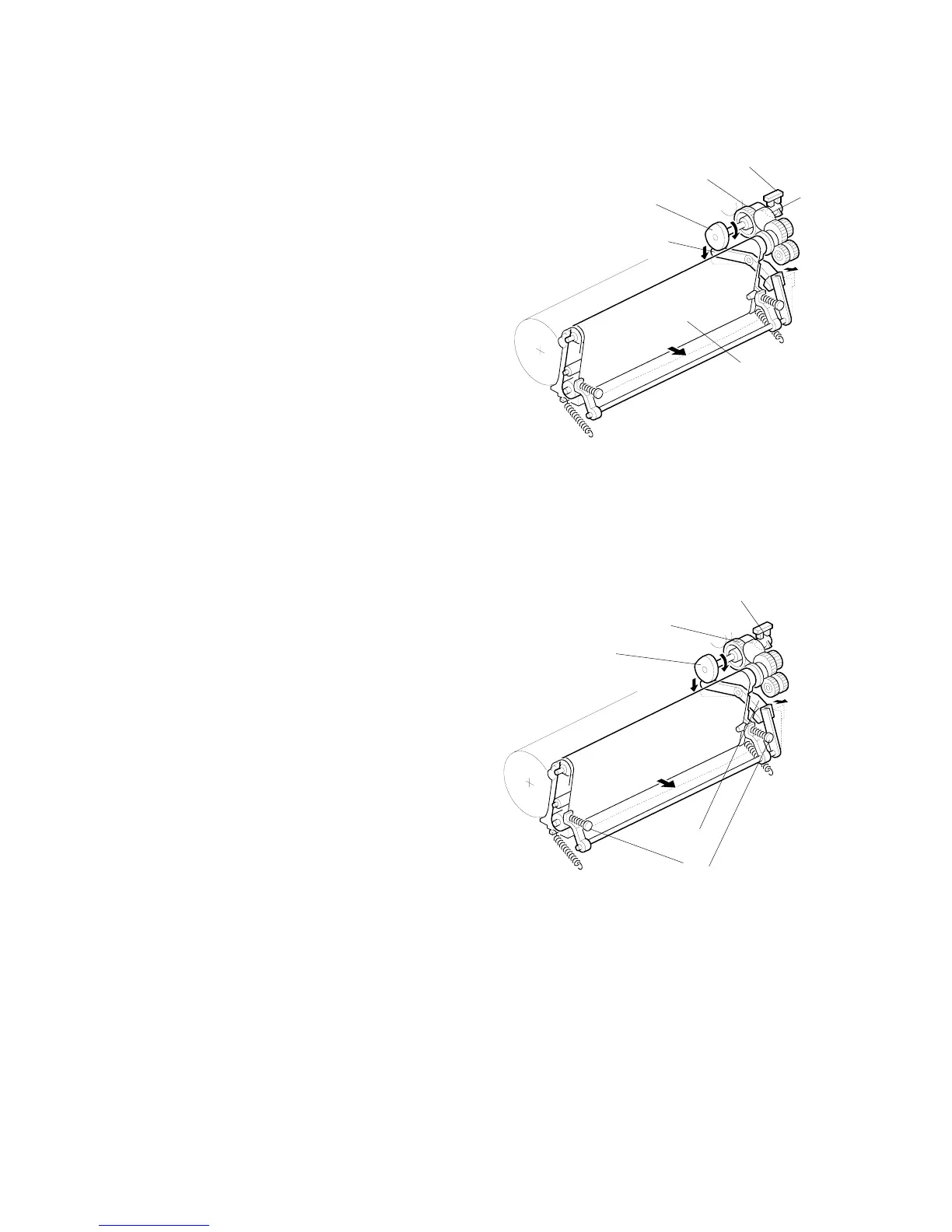

6.14.3 TRANSFER BELT UNIT CONTACT MECHANISM

The belt contact and release mechanism

consists of the belt contact clutch [A], cam

[B], and contact lever [C]. The belt contact

clutch turns on and the cam attached to

the clutch rotates half a complete rotation.

The contact lever, riding on the cam, is

lifted up and the springs [D] push the belt

into contact with the drum.

The transfer belt position sensor [E]

detects the home position of the cam (this

is when the belt is away from the drum).

The belt must be released from the drum

between copy jobs in order to prevent the

ID sensor pattern from being rubbed off

and to prevent contamination of the drum

from the surface of the belt.

B195D968.WMF

B195D969.WMF

[A]

[B]

[C]

[D]

[E]

[F]

[A]

[B]

[C]

[E]

[D]

Loading...

Loading...