SM 6-23 G147

Detailed

Descriptions

which was read from the bare drum at the same time.

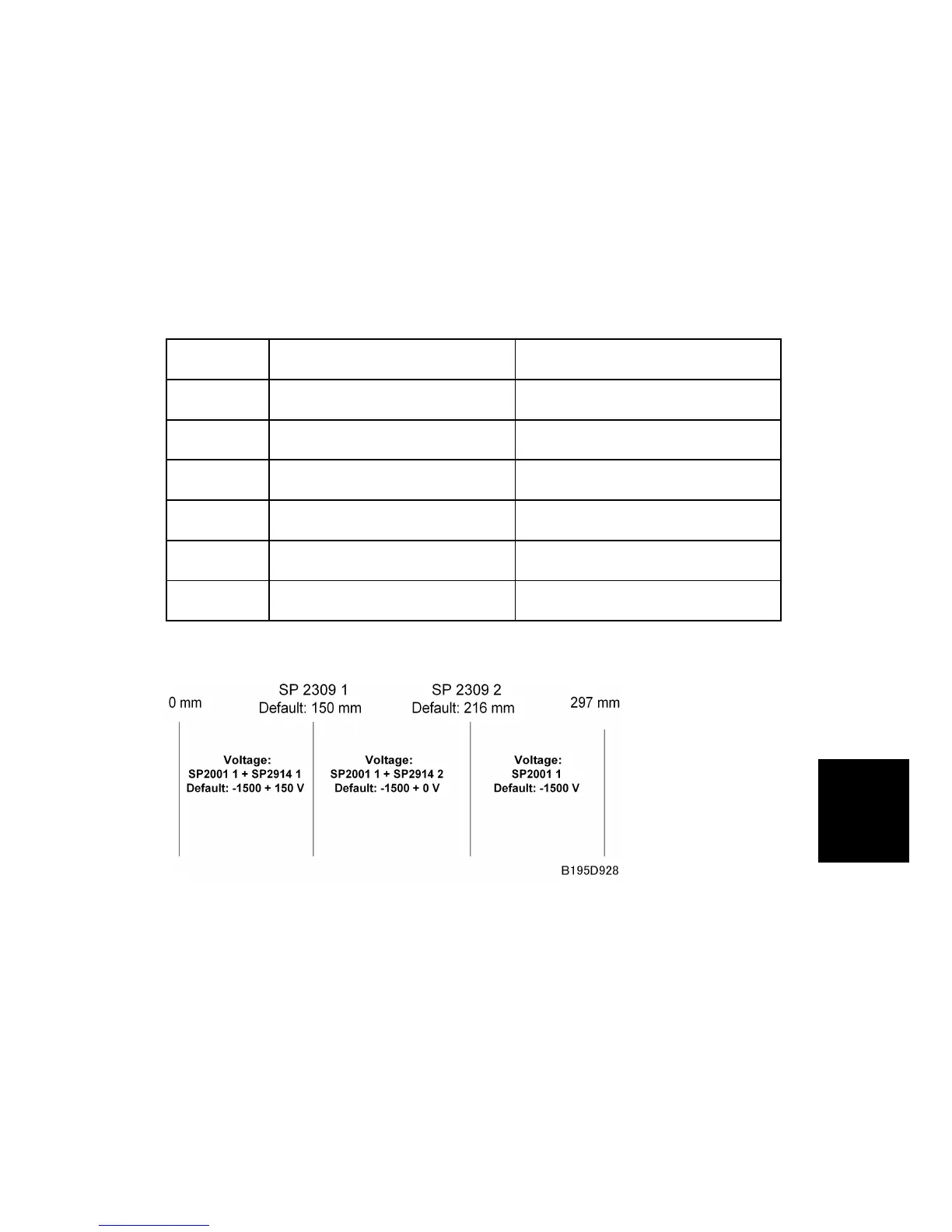

Correction for Paper Width and Thickness (By-pass Tray only)

The by-pass tray can be used for non-standard paper narrower than sizes accepted by the

paper trays. Thicker paper, OHP sheets, etc. can also be loaded in the by-pass tray but

adjustments must be performed with the SP modes listed below in order to avoid jams and

quality problems.

SP Mode SP Name

SP2001-01 Charge Roller Bias Adjustment Default: –1,480 V

SP2001 02 ID Sensor Pattern Default: -200 V

SP2309-01 Paper Lower Width [a] Width limit. Default: 150 mm

SP2309-02 Paper Upper Width [b] Width limit. Default: 216 mm

SP2914-01 Process Ctrl Set – C alpha Adjust 10 V/step. Default: +150 V

SP2914-02 Process Ctrl Set – C beta Adjust 10 V/step. Default: 0

The way that these SP modes are used is shown below.

For example, with the default settings, if the paper width fed from the by-pass tray is 100 mm,

the charge roller voltage will be –1,480 + 150 V.

6.6.3 ID SENSOR PATTERN PRODUCTION TIMING

An ID sensor pattern is created on the drum:

Every time the system is powered up

After every 10 prints

After 100 prints

After 200 prints

Loading...

Loading...