7. MAINTENANCE INFORMATION

7.1. RECOMMENDATIONS FOR MAINTENANCE

- Stop the machine (as indicated in paragraph “machine safe stop”).

- Proper maintenance will allow a longer life span and constant compliance with safety requirements.

- Before performing any operation, the authorised operator must make sure to have understood the “Instructions

for use”.

- Pay attention to the safety warnings, do not misuse the machine and assess the possible residual risks.

- Carry out the interventions with all the safety devices enabled and wear the required PPE.

- Indicate the intervention areas and prevent access to the devices that, if activated, could cause unexpected

hazards and compromise safety.

- Do not carry out interventions that are not described in the manual but contact an service centre authorised by

the Manufacturer.

- Do not dispose of materials, polluting liquids and the waste generated during the interventions into the

environment but dispose of them according to the standards in force.

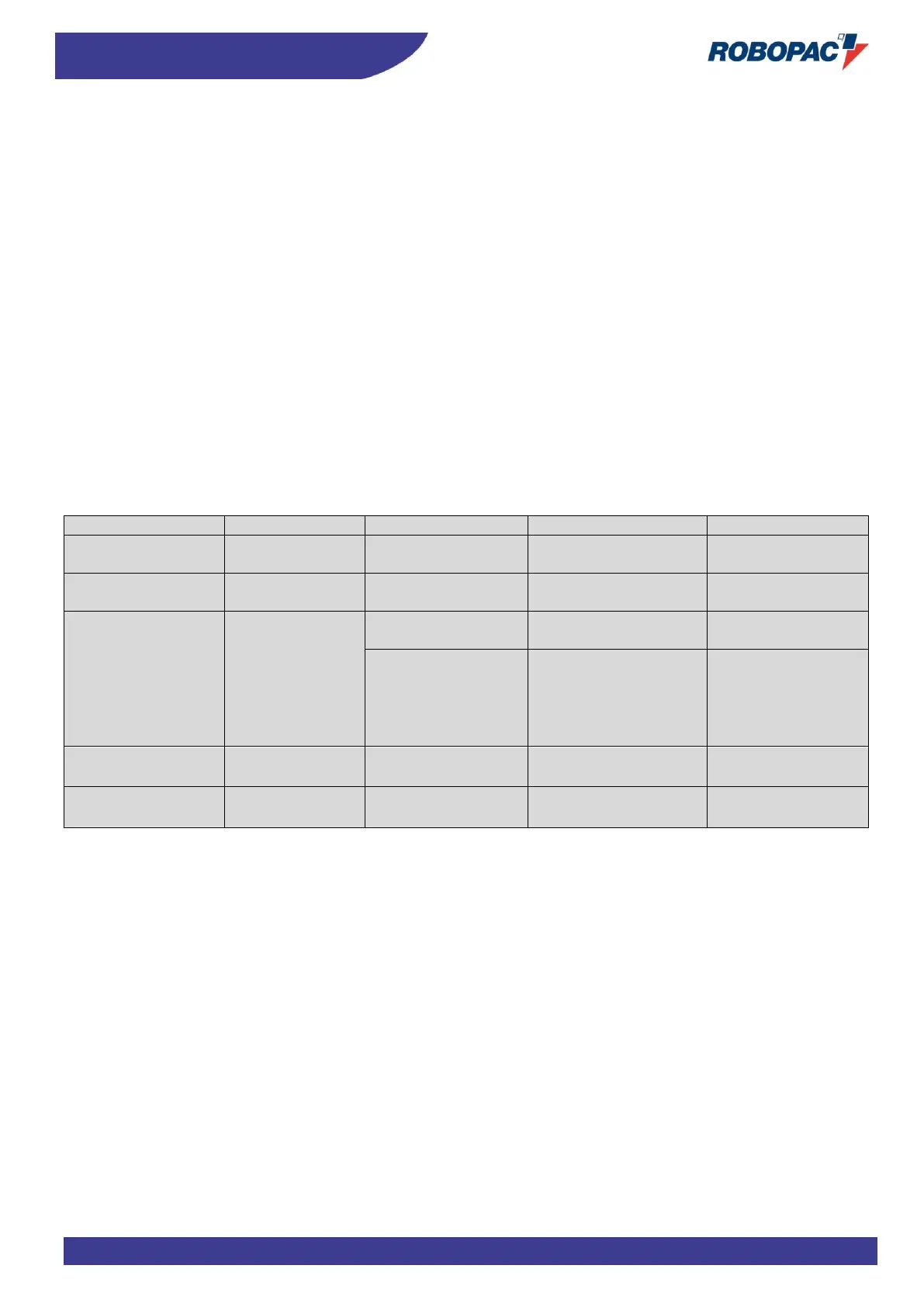

7.2. PERIODICAL MAINTENANCE INTERVALS

The table indicates the scheduled maintenance intervals which allow to obtain best performance, long operating life and

a constant level of safety.

Maintenance interval table

1

Do not top up and/or change in life-lubed reduction units and gearmotors.

Cycle timings have been defined on the basis of the standard cycle.

The standard cycle is the following: 500 mm high film reel, 1500 mm high pallet, pallet weight equal to 1500 kg,

total wrapping cycle consisting of two turns at the base, two turns at the top with rotation speed of 12 r.p.m. or

80 m/1’ and carriage upstroke and downstroke speed equal to 4 m/1’.

Loading...

Loading...