Troubleshooting 10-19

1560D-UM051D-EN-P – February 2005

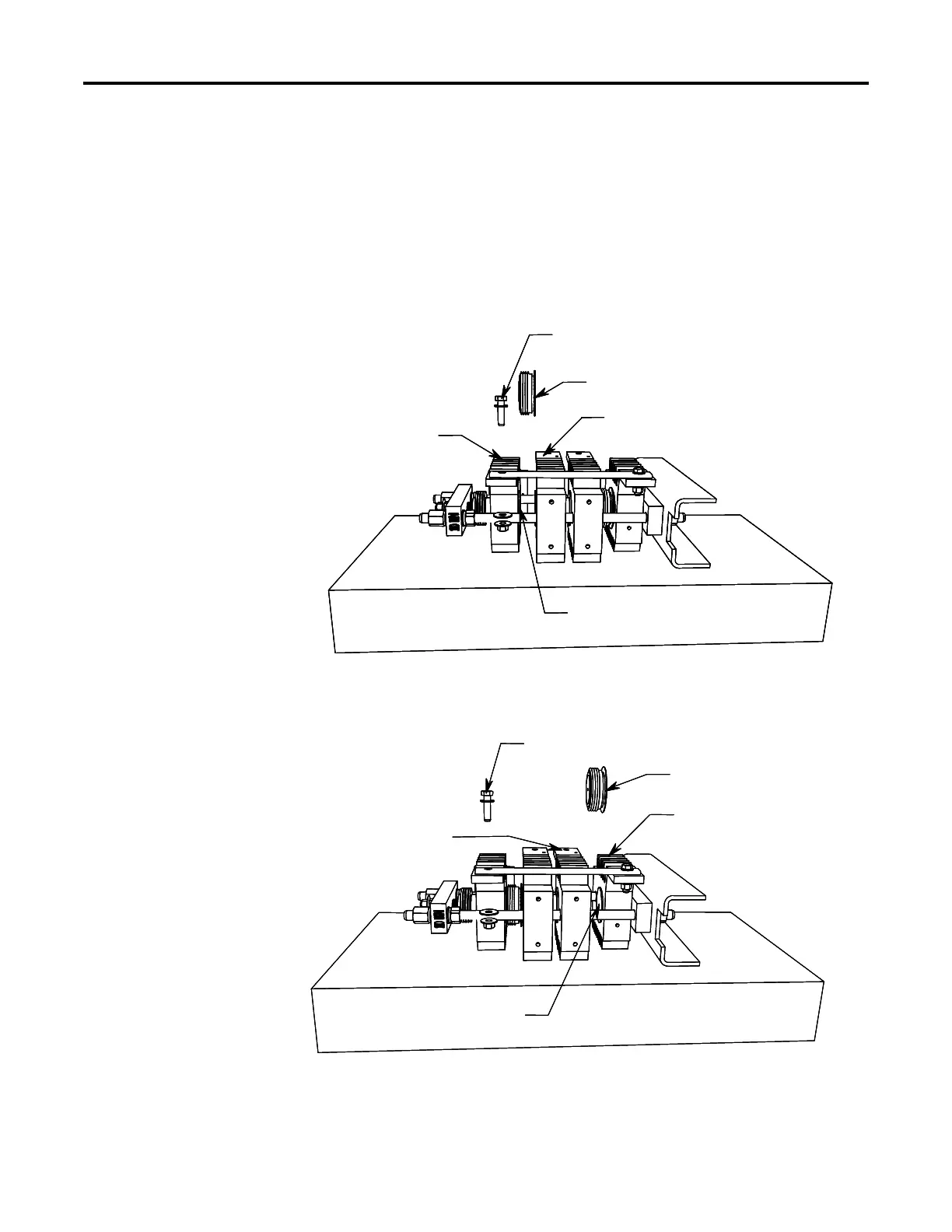

Figure 10.5 – Removal of SCR1

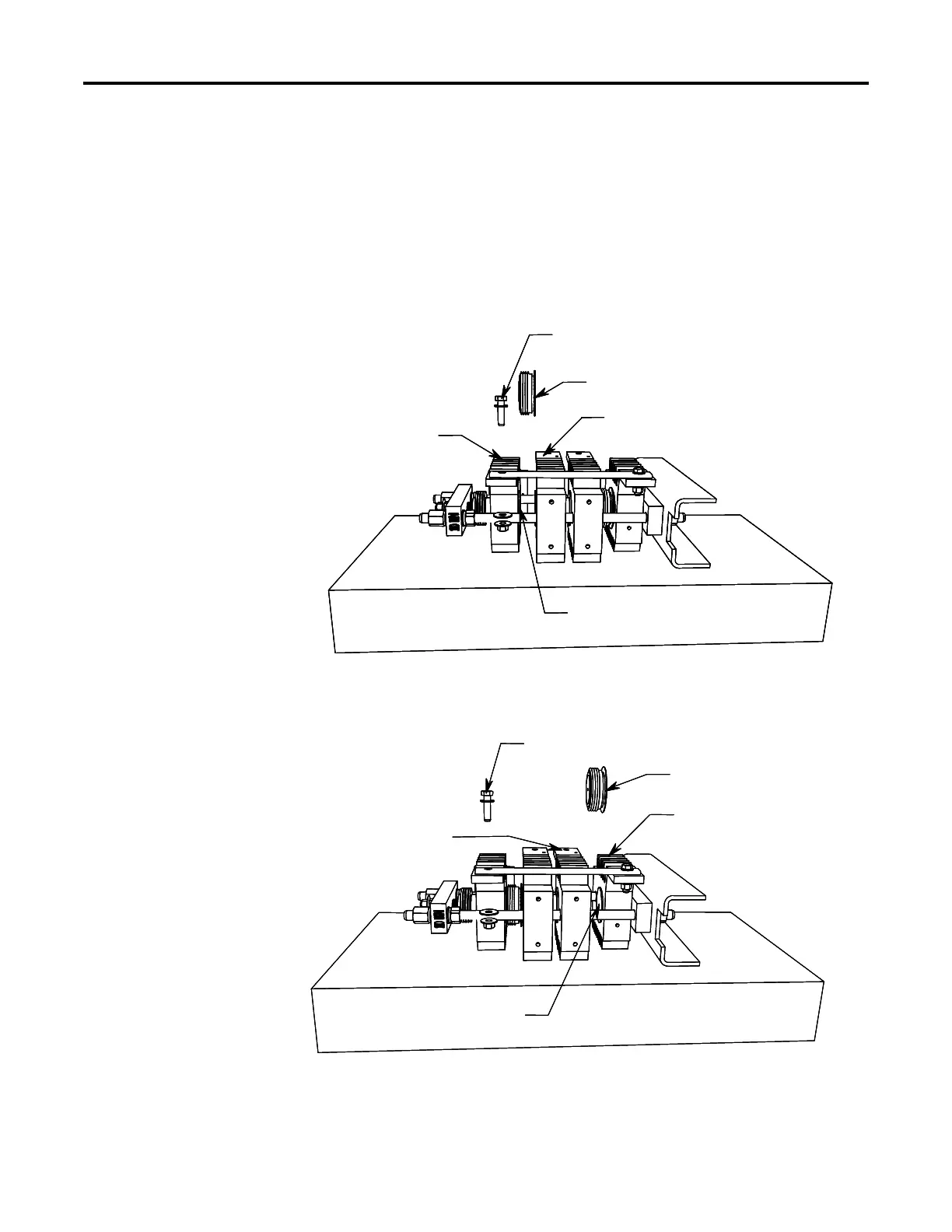

Figure 10.6 – Removal of SCR2

Shorting Bar Hardware

SCR 2

Heatsink 3

Heatsink 2B

Locating Pin

Shorting Bar Hardware

SCR 2

Heatsink 3

Heatsink 2B

Locating Pin

To Remove SCR1:

• Remove shorting bar hardware

• Pry Heatsinks 1 and 2A apart

• Extract SCR

To Insert New SCR:

• Apply thin film of electrical joint compound to

surfaces of SCR

• Install SCR so that it is seated in locating pin of

heatsink (note orientation of SCR).

• Pry heatsinks to close gap, ensuring that SCR is

seated properly in both its locating pins.

• Rotate SCR so that all leads have same direction.

Shorting Bar Hardware

SCR 1

Heatsink 2A

Heatsink 1

Locating Pin

NOTE: The following steps pertain to the 180/360A

power stack assembly with four heatsinks. The

process is similar for a power stack assembly with

only three heatsinks.

To Remove SCR1:

• Remove shorting bar hardware

• Pry Heatsinks 1 and 2A apart

• Extract SCR

To Insert New SCR:

• Apply thin film of electrical joint compound to

surfaces of SCR

• Install SCR so that it is seated in locating pin of

heatsink (note orientation of SCR).

• Pry heatsinks to close gap, ensuring that SCR is

seated properly in both its locating pins.

• Rotate SCR so that all leads have same direction.

Shorting Bar Hardware

SCR 1

Heatsink 2A

Heatsink 1

Locating Pin

Shorting Bar Hardware

SCR 1

Heatsink 2A

Heatsink 1

Locating Pin

NOTE: The following steps pertain to the 180/360A

power stack assembly with four heatsinks. The

process is similar for a power stack assembly with

only three heatsinks.

Loading...

Loading...