Commissioning Procedures 3-5

1560D-UM051D-EN-P – February 2005

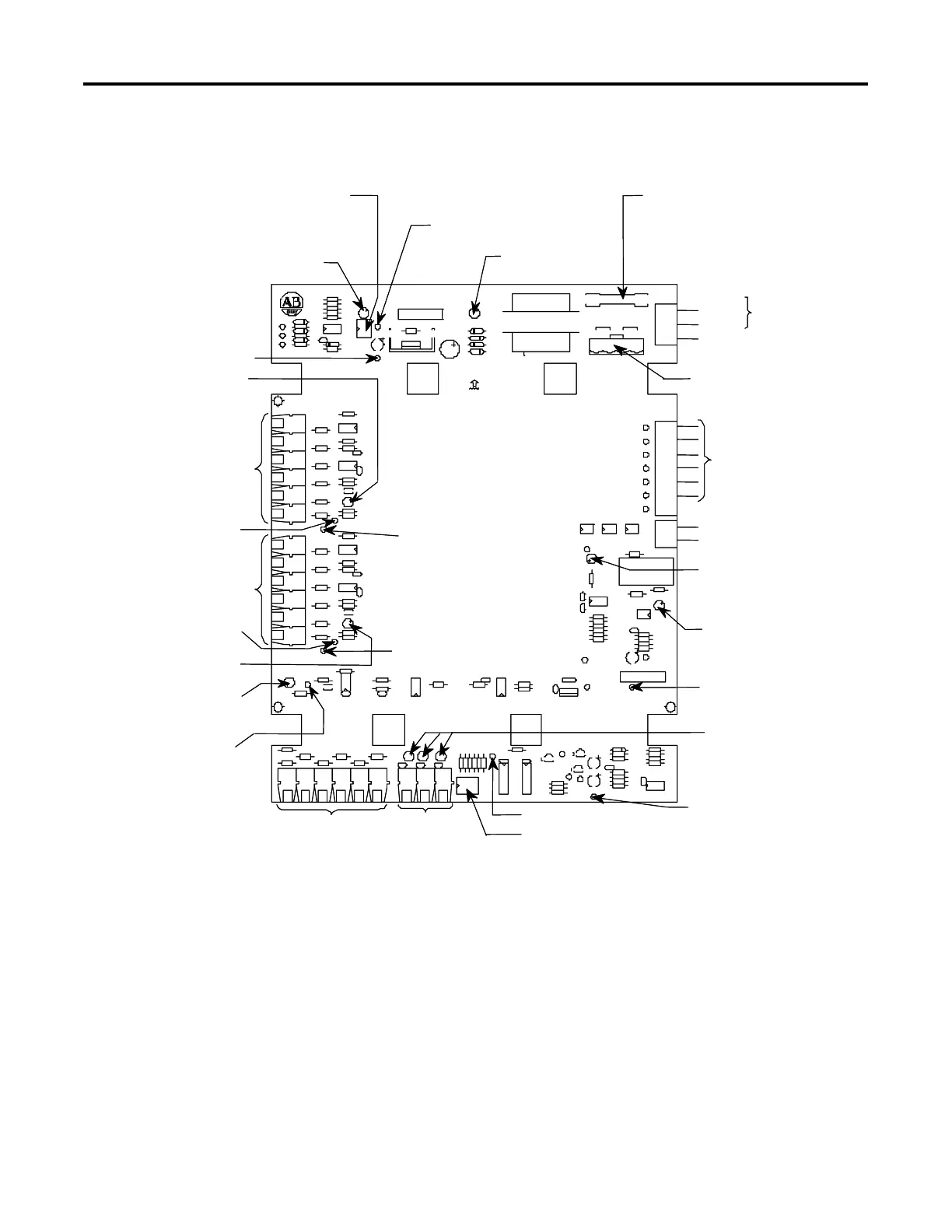

POWER

L

N

G

DIP 1: Pulse – Turn ON (slide up) to

apply test pulses to gate drive circuits.

NOTE: Must be OFF for normal operation.

LED 2 (Red): Pulse – ON

when test pulses on.

Test Point 1 (COM)

LED 3 (Yellow): Phase A

ON when gate signal present

Phase A Fibre Optic Transmitters.

Send gate signals to gate driver

board via fibre optic cables.

All transmitters within a phase

are in series and are driven

simultaneously. (See note 2)

Test Point 1 (COM)

Test Point 10:

Phase A Gate Signal

Phase B Fibre Optic Transmitters

(See note 2)

Test Point 11:

Phase B Gate Signal

Test Point 1 (COM)

LED 4 (Yellow) ON when

Phase B gate signal present

LED 5 (Yellow) ON when

Phase C gate signal present

Test Point 12:

Phase C Gate Signal

Phase C Fibre Optic

Transmitters

(See note 2)

Temperature

feedback fibre

optic receivers.

One cable from a

gate driver board

in each phase.

Test Point 3: +5 V

DIP 2: Use to defeat individual or all temperature feedback channels.

Switch 4 must be OFF for normal operation. If there are fibre optic

cables present in the blue receivers to the left, the corresponding

switch(es) must be OFF (press in at bottom to turn off). If a blue

receiver does not have a cable plugged in, the corresponding switch

must be ON.

Test Point 1 (COM)

LED 8, LED 9, LED 10 (Green)

ON when signal present at

temperature feedback fibre

optic receiver(s).

Test Point 1 (COM)

LED 6 (Red): UTS status.

ON when Dialog UTS signal

is true.

LED 7 (Red): VF inhibit.

ON when voltage feedback

signals are inhibited.

UTS: Dialog Term. 19

Control Common

Motor voltage inputs

from voltage feedback

board

Voltage Selection Plug (TB2):

Apply jumpers per rated

control voltage range.

NEUTRAL

GROUND

LINE

Control Power:

100-120 or 220-240 VAC

50 or 60 Hz

Control Fuse (F1): Replace with

Indicated size and type, depending on

rated control voltage.

Part Numbers: 1/10A – 80174-028-02

1/16A – 80174-028-01

LED 1 (Green): Power

ON when control power

applied.

Test Point 2:

+12 V

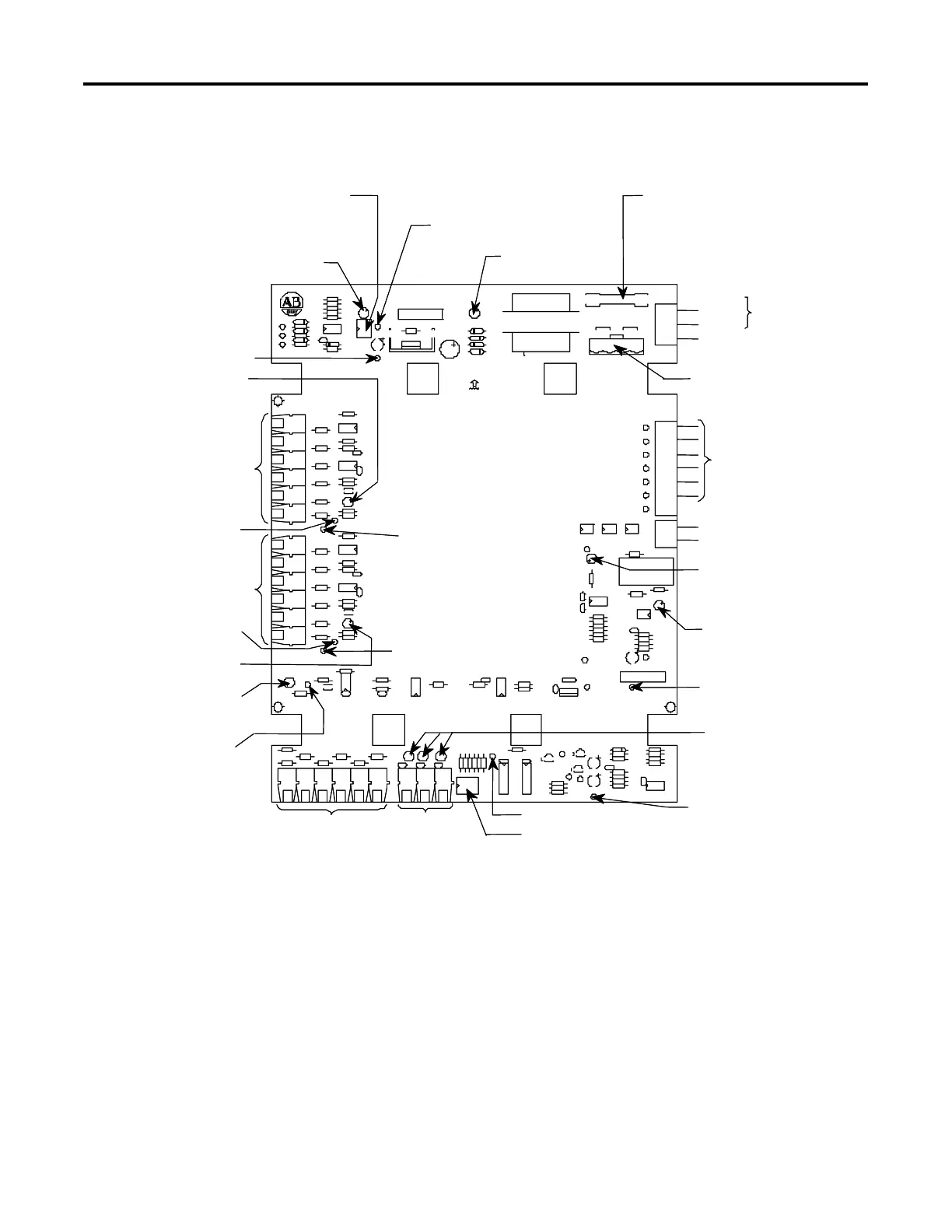

POWER

L

N

G

DIP 1: Pulse – Turn ON (slide up) to

apply test pulses to gate drive circuits.

NOTE: Must be OFF for normal operation.

LED 2 (Red): Pulse – ON

when test pulses on.

Test Point 1 (COM)

LED 3 (Yellow): Phase A

ON when gate signal present

Phase A Fibre Optic Transmitters.

Send gate signals to gate driver

board via fibre optic cables.

All transmitters within a phase

are in series and are driven

simultaneously. (See note 2)

Test Point 1 (COM)

Test Point 10:

Phase A Gate Signal

Phase B Fibre Optic Transmitters

(See note 2)

Test Point 11:

Phase B Gate Signal

Test Point 1 (COM)

LED 4 (Yellow) ON when

Phase B gate signal present

LED 5 (Yellow) ON when

Phase C gate signal present

Test Point 12:

Phase C Gate Signal

Phase C Fibre Optic

Transmitters

(See note 2)

Temperature

feedback fibre

optic receivers.

One cable from a

gate driver board

in each phase.

Test Point 3: +5 V

DIP 2: Use to defeat individual or all temperature feedback channels.

Switch 4 must be OFF for normal operation. If there are fibre optic

cables present in the blue receivers to the left, the corresponding

switch(es) must be OFF (press in at bottom to turn off). If a blue

receiver does not have a cable plugged in, the corresponding switch

must be ON.

Test Point 1 (COM)

LED 8, LED 9, LED 10 (Green)

ON when signal present at

temperature feedback fibre

optic receiver(s).

Test Point 1 (COM)

LED 6 (Red): UTS status.

ON when Dialog UTS signal

is true.

LED 7 (Red): VF inhibit.

ON when voltage feedback

signals are inhibited.

UTS: Dialog Term. 19

Control Common

Motor voltage inputs

from voltage feedback

board

Voltage Selection Plug (TB2):

Apply jumpers per rated

control voltage range.

NEUTRAL

GROUND

LINE

Control Power:

100-120 or 220-240 VAC

50 or 60 Hz

Control Fuse (F1): Replace with

Indicated size and type, depending on

rated control voltage.

Part Numbers: 1/10A – 80174-028-02

1/16A – 80174-028-01

LED 1 (Green): Power

ON when control power

applied.

Test Point 2:

+12 V

NOTES:

1. All test point voltages or signals are relative to TP1 (COM) except TP6 “TEMP MODULE” which is relative to TP19 “TEMP COM” only.

TP19 must not be connected to ground or TP1 “COM”. There are several TP1 locations on the board for convenience.

2. There are two versions of the circuit board: -51 and -53 have four fibre optic transmitters per phase (for <2700 volt operation, only two

per phase will be utilized); -52 and -54 have six fibre optic transmitters per phase for >5000 volt operation.

3. Part numbers 80187-131-51 and -52 are factory set for 100-120 VAC control power. 80187-131-53 and -54 are factory set for 220-240 VAC

control power. They can be changed in the field by moving the jumpers on the voltage selection plug (TB2) and changing the fuse (F1).

Figure 3.1 – Connection and Test Information for Interface Board

Loading...

Loading...