Automatic Zero Setting

Activate the automatic zero setting function only in

clearly defined cases, e.g. if some belt circuits are run

with no load.

Parameter H 01 = JA Automatic active

= NO Automatic not active

Automatic system is active both in turned-on and

turned-off state of scale, if belt speed exceeds Vmin.

Measuring result of one belt circuit is continuously

compared to previous result.

If “Belt Empty” is identified, zero point is automatically

corrected.

Set continuous plausibility check with Parameters H

02 and H 03. For normal conveyor belts, default

values can be used, however, a check is

recommended.

1. Deactivate automatic H 01 = NO.

2. Call zero setting program via function distributor

various times and acquire result.

3. Note final results Dev. (upper display) as of

second run.

4. The highest value of Item 3 is the smallest value

for Parameter H 02.

Enter double to triple value, but min. 0.1 %.

.

5. Parameter H04 monitors the total of all zeroing

operations. Enter value, e.g. 2...4 times higher

than H 02.

6. Activate Automatic using Parameter H 01.

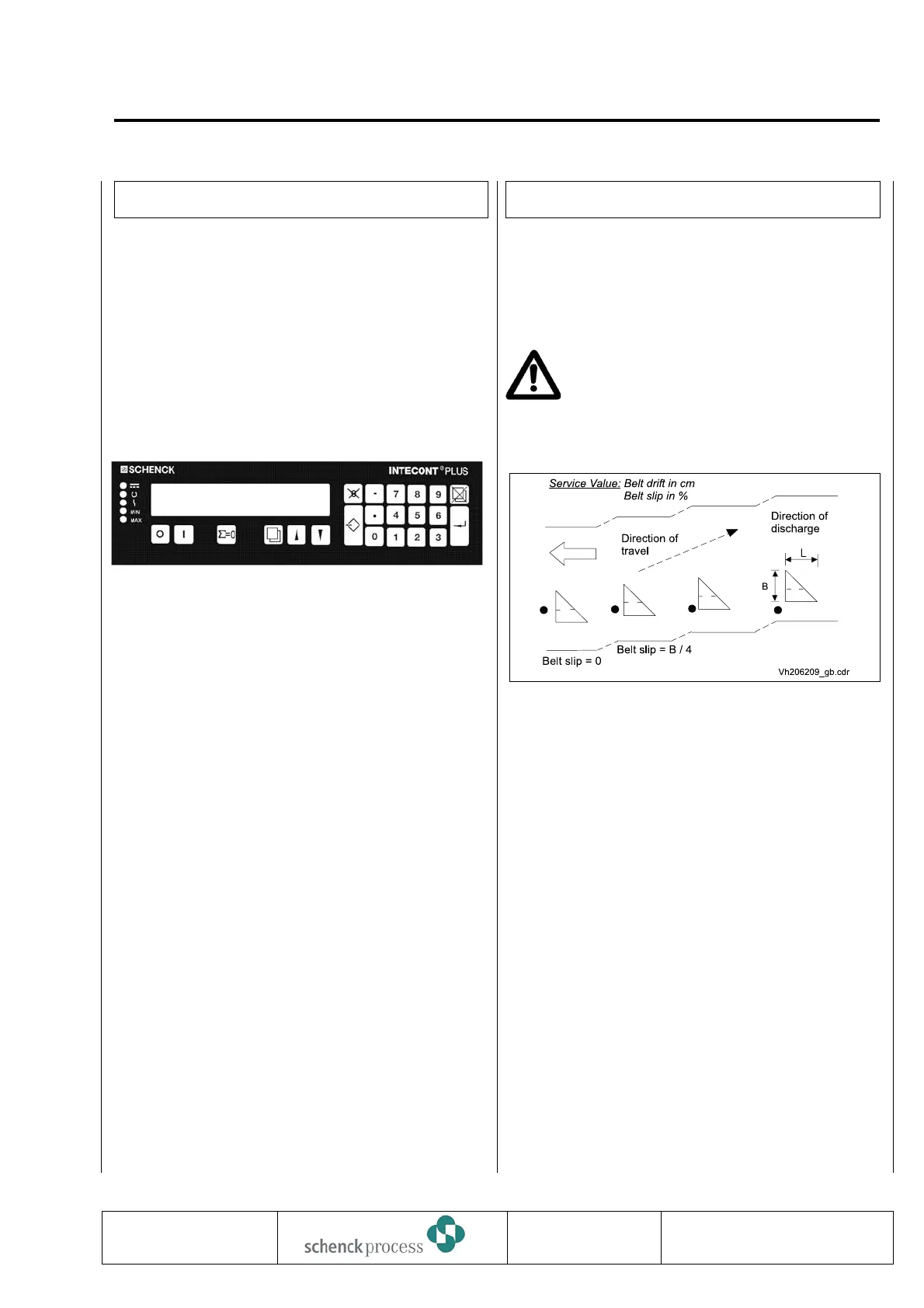

Belt Run Monitoring

INTECONT comes with belt a belt run monitoring

function designed to detect belt drift and belt slip.

Activate monitoring using Parameter N03 “Belt Sensor

Active”.

The belt run monitoring functions can be used only if a

belt circuit sensor (Namur transducer) and

a triangle metal sensor area on belt area

available (see Fig. Below). If not,

Parameters N03 “Belt Sensor Active” and

N05 “BIC Active” must be set to “NO.

To activate belt run monitoring:

1. Set Parameter N03 “Belt Sensor Active” to

“YES”.

2. Enter sensor length L into Parameter N06

“Sensor Length” (s. Belt Run Monitoring figure).

3. Enter sensor width B into Parameter N07

“Sensor Width” (s. Belt Run Monitoring figure).

4. Set Parameter N08 “Sensor Offset” to 0.

5. Call calibrating function “LB: IMP/Belt”.

6. Acquire result after min. 2 belt circuits.

7. Adjust sensor.

Note: Service value ”Imp.S” indicates the

number of pulses measured for the covered

sensor. If the belt sensor is located exactly in mid

sensor area, the following value results:

Imp.S. = 0.5 * L (N06) * 0.01 * vs_Charact. Val.

(B04)

Example: N06 = 8.40 cm and

B04 = 1000 I/m result in Imp.S. = 42

0837

INTECONT PLUS VBW

Commissioning

BV-H2214 GB 91

Transmission to third parties and reproduction of

this documentation are not permitted.

SchenckProcess GmbH reserves all rights of

ownership and copyrights.

Technische

Redaktion PDE-RD

Z1 = 2500 kg

I = 0 kg/h

Fig.: Belt Run Monitoring

Loading...

Loading...