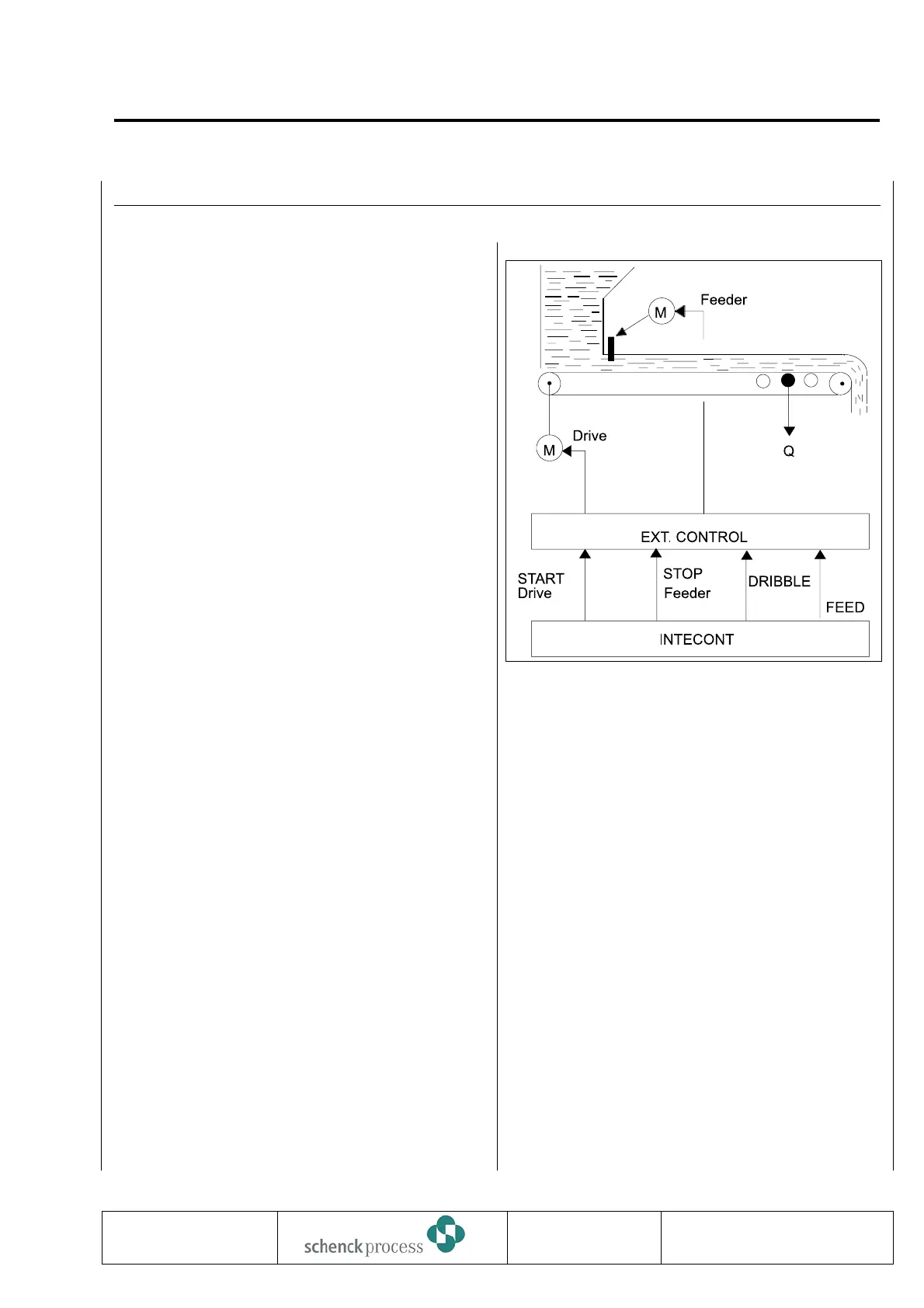

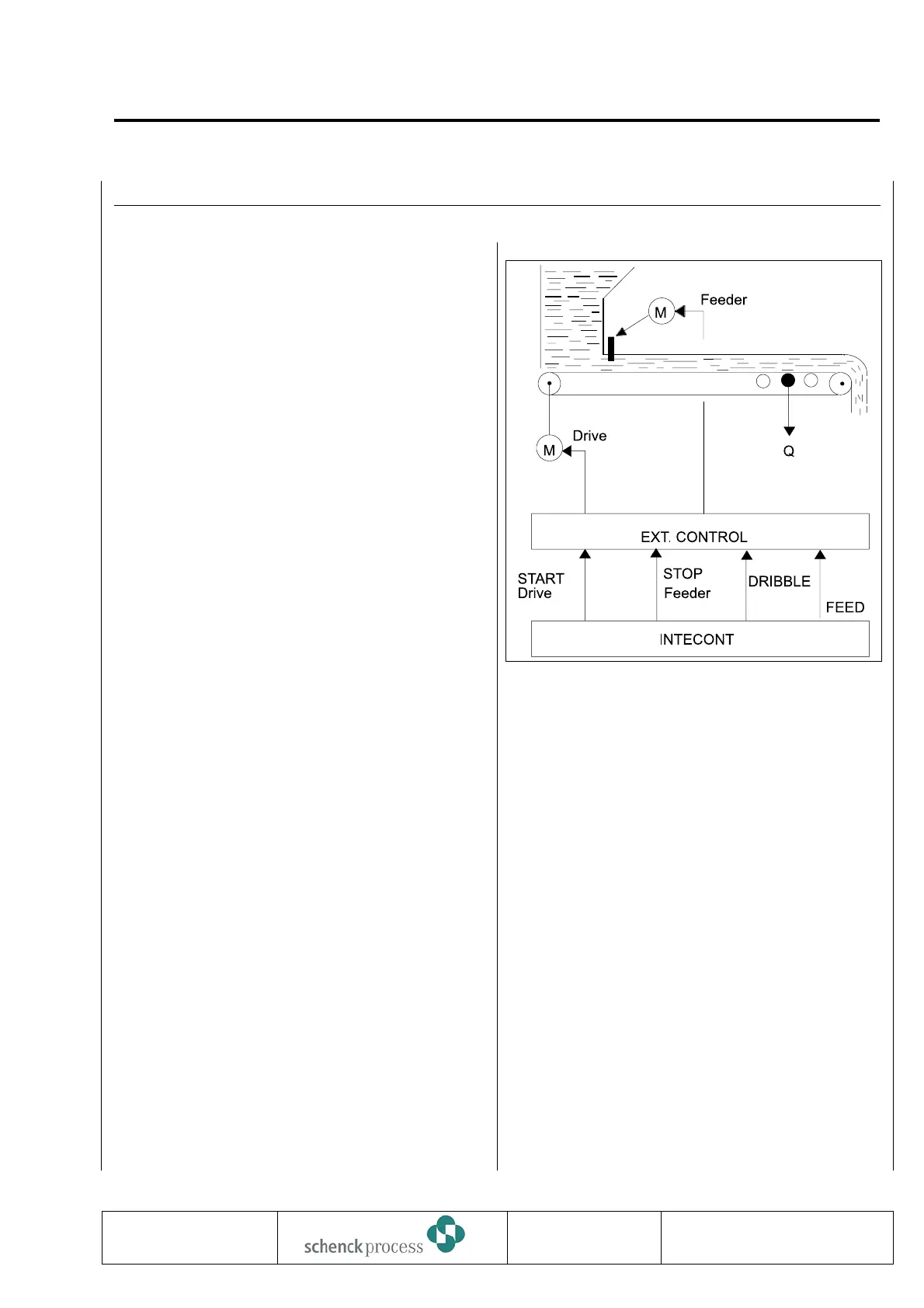

Batching Without Clearance

If batch is complete, belt drive is cut-off. Feeding by

full feed/dribble feed can be controlled via belt speed

or prefeeder (dashed line).

It is recommended to activate delay for material

discharge (O 01 = YES).

Select keyboard as START source

(B 06 = DE + T).

For details, see OPERATION chapter.

Parameter Schedule:

B 06 START source OP

G 06 Belt tracking time Tn apr. 3 s

Feed rate determination tracking time after

belt cut-off.

Enables afterflowing material to be acquired.

N 01 CPD Active YES

Delay for point of discharge

I 01 Batch Dribble Feed kg

Change-over point from full feed to dribble

feed, e.g. by belt speed reduction. Enter

deviation from cut-off point I 02 (see Figure).

I 02 Batch Cut-Off Point kg

Belt drive cut-off point. To be set to slightly

below setpoint to enable afterflowing material

to be acquired.

Suggestion:

Mean dribble feed feed rate in kg/h divided by

3600.

I 03 Correction Factor 0.6

Dribble feed changeover and cut-off points

are automatically adapted upon completion of

batch for system to be better matched to

actual conditions until the time of next

batching operation.

I 03 = 0 : No adaptation

I 03 = 1 : Full adaption

Intermediate values lead to filtered

adaptation.

Suggestion: I 03 = 0.6

I 04... For monitoring, see Parameter List.

I 07 Empty Belt NO

Prerequisite for batching mode.

M 01 Feeder Active

NO : Feeder control output is always

LOW. Full feed/dribble feed

changeover must be controlled via

belt drive. Function “Next W/Belt

Empty” is not possible.

YES : Prerequisite for feeder control via

batch mode and for function

“START/STOP Feeder”.

0837

INTECONT PLUS VBW

Details

BV-H2214 GB 95

Transmission to third parties and reproduction of

this documentation are not permitted.

SchenckProcess GmbH reserves all rights of

ownership and copyrights.

Technische

Redaktion PDE-RD

Loading...

Loading...