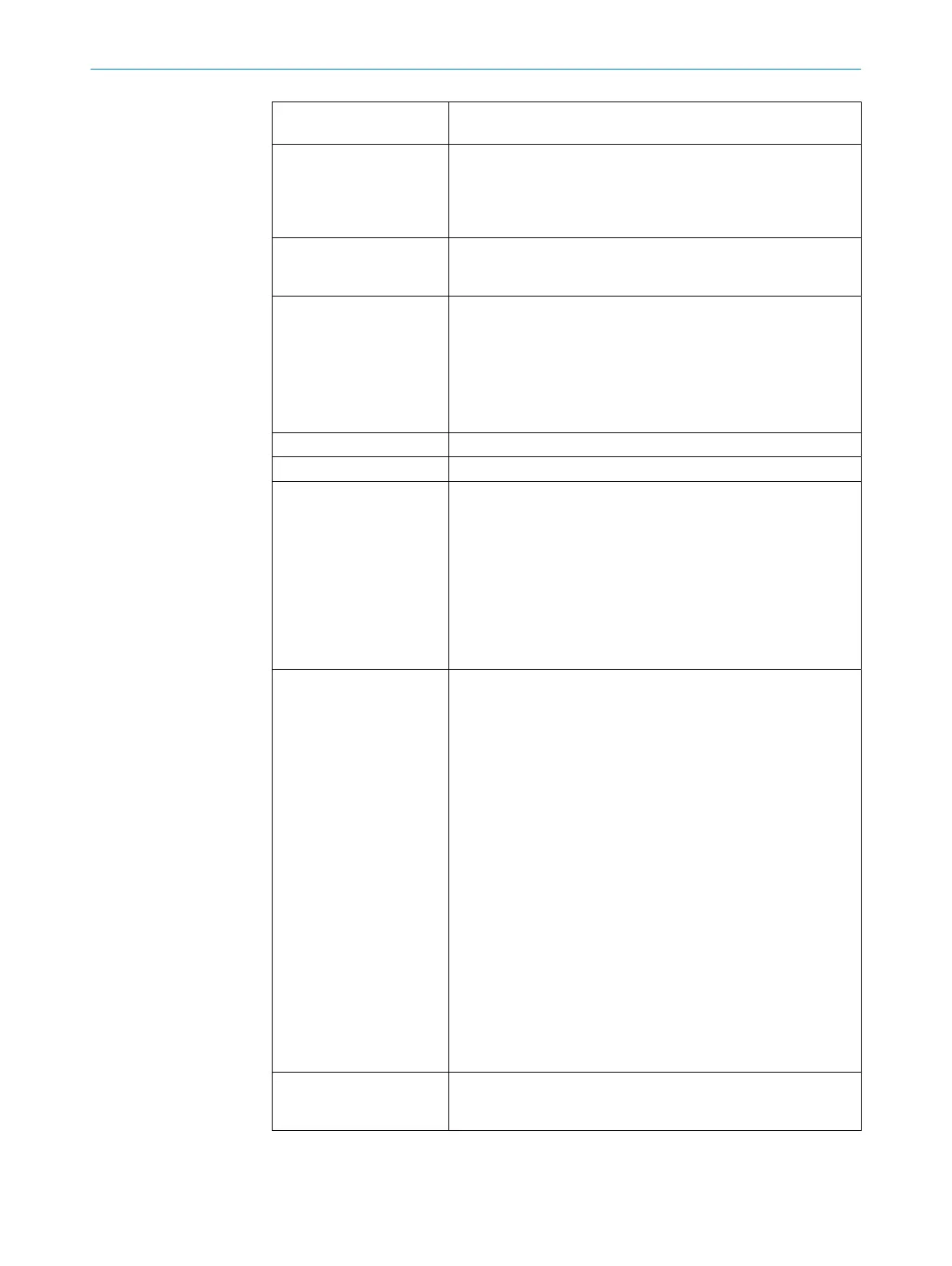

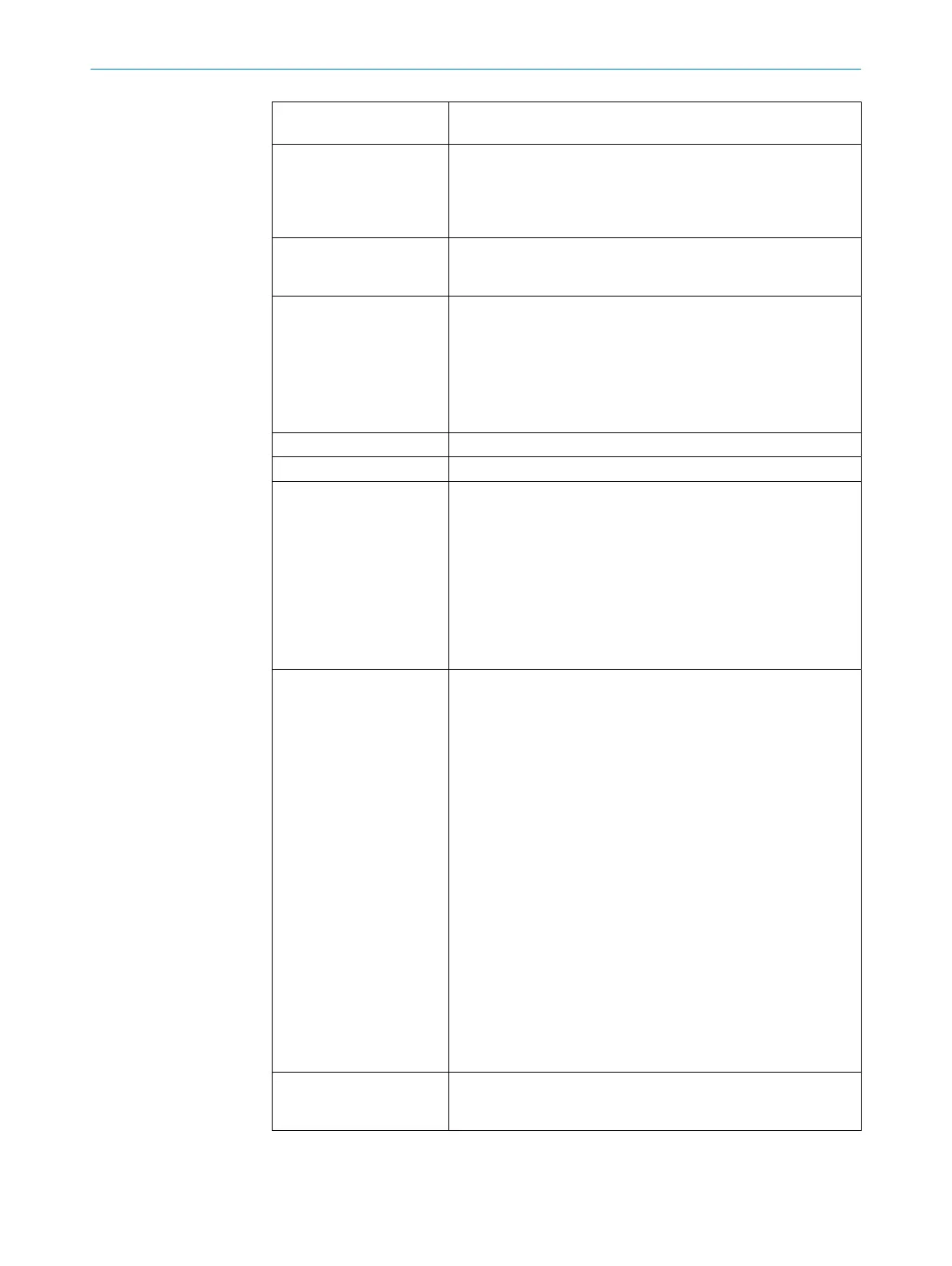

NFC Near field communication. International transmission standard for

t

he contactless exchange of data by electromagnetic induction.

OFF state The OFF state is the status of the outputs of the protective device,

where the controlled machine is triggered to quit its dangerous

state and the start-up of the machine is prevented (e.g., the volt‐

age at the OSSDs is LOW, so that the machine is switched off and

remains still).

ON state The ON state is the status of the outputs of the ESPE, where the

cont

rolled machine is permitted to operate (e.g., the voltage at the

OSSDs is HIGH so that the machine can run).

OSSD Output signal switching device: signal output for the protective

device, which is used for stopping the dangerous movement.

An OSSD is a safety switching output. The functionality of each

OSSD is tested periodically. OSSDs are always connected in pairs

and must undergo dual-channel analysis for safety reasons. An

OSSD pair is formed from 2 OSSDs that are connected and ana‐

lyzed together.

PFHD Probability of dangerous failure per hour

PL Performance level (ISO 13849)

Protective field The protective field protects the hazardous area of a machine or

v

ehicle. As soon as the electro-sensitive protective device detects

an object in the protective field, it switches the associated safety

outputs to the OFF state. This signal can be passed to controllers

resulting in the dangerous state coming to an end, e.g. to stop the

machine or the vehicle.

A horizontal or vertical protective field is required, depending on

the application. The electro-sensitive protective device can there‐

fore be mounted in horizontal or vertical alignment, depending on

the requirements.

Reset When a protective device has sent a stop command, the stopped

s

tate must be maintained until a reset device is activated and the

machine can be restarted in a second step.

The reset brings the protective device back to the monitoring state

after it has sent a stop command. The reset also quits the start-up

or restart interlock of a protective device, so that the machine can

be restarted in a second step.

The reset must only be possible, when all safety functions and

protective devices are functional.

The reset of the protective device must not introduce any move‐

ment or dangerous situations itself. The machine is only permitted

to start after the reset once a separate start command has been

sent.

•

Manual resets are performed using a separate, manually oper‐

ated device, such as a reset pushbutton.

•

Automatic resets by the protective device are only permitted in

special cases, if one of the following conditions is met:

°

It must not be possible for people to be in the hazardous

area without triggering the protective device.

°

It must be ensured that no people are in the hazardous

area during or after the reset.

Resolution The resolution of an active opto-electronic protective device (also

k

nown as the sensor detection capability) is the minimum size of

an object for it to be reliably detected.

16 GLOSSARY

84

O P E R A T I N G I N S T R U C T I O N S | scanGrid2 I/O 8025936/2021-01-08 | SICK

Subject to change without notice

Loading...

Loading...