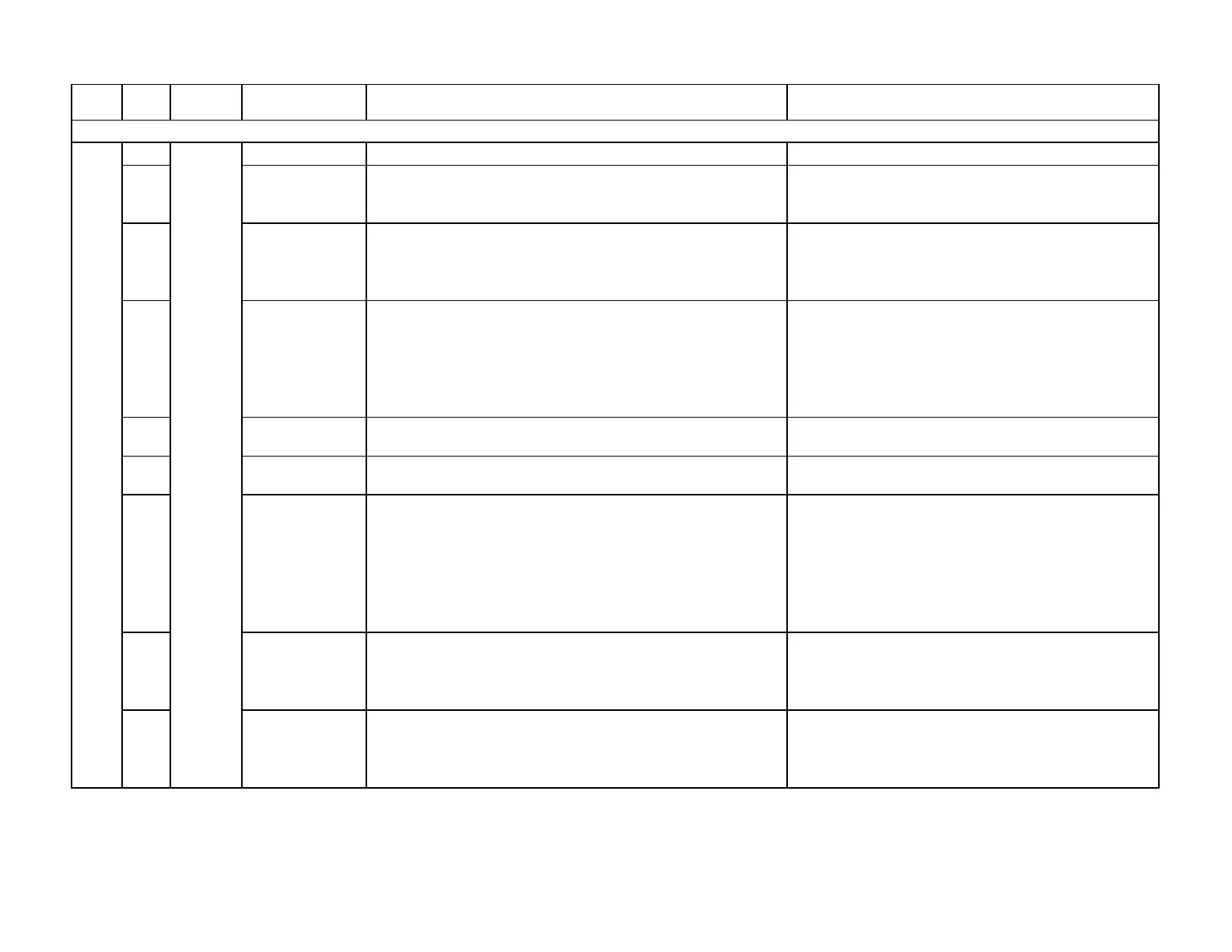

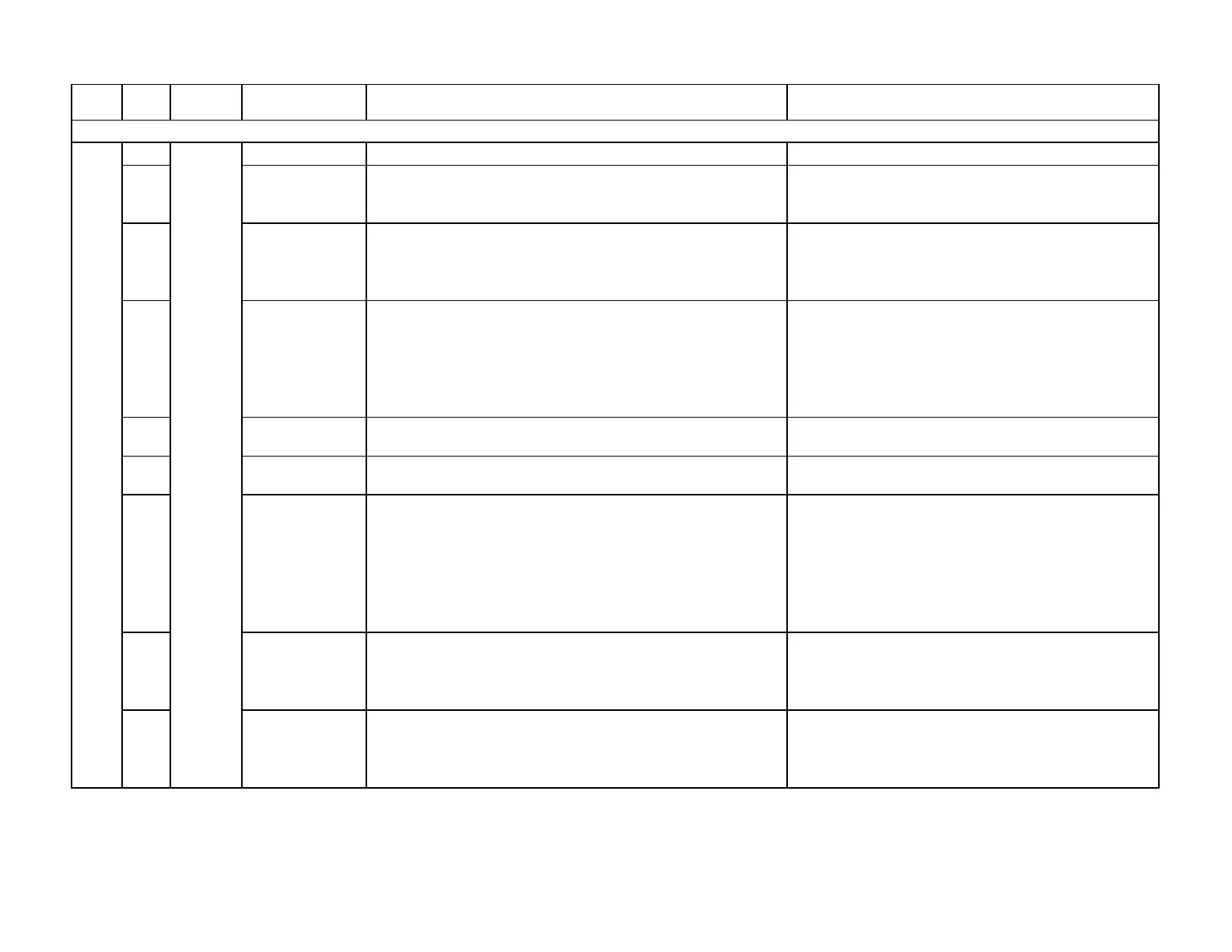

Device Display Meaning for the LMV5x System Corrective Action

Any # - O2 trim control fault See diagnostic code.

01

Missing or faulty

Control

Parameters

PID parameter for controller algorithm missing Check the O2 trim PID control parameters.

02

Missing or faulty

O2 controller

manipulated

variable limitation

The parameters for limiting the O2 controller manipulated

variable have not yet been set

Check the parameters (O2MinManVariable and

O2MaxManVariable ) for limiting the O2 controller

manipulated variable and reset if necessary.

03

O2 controller

manipulated

variable limitation

The O2 controller manipulated variable is limited

1) Check the settings of the O2 trim control.

2) Check that the O2 sensor is installed correctly.

3) Check that the O2MaxManVariable and

O2MinManVariable parameters are set correctly

(especially when copying parameters from devices

before software version 05.00 and 10.10).

04

O2 curves

incomplete

Missing value in the O2 trim control curves

Check for missing values in the O2 control curve, O2

ratio control curve, or O2 minimum value curve.

05

Internal Fault

Basic Unit

- If fault occurs constantly: Replace LMV5

06

Faulty set

temperature or

supply air

temperature

There is no valid supply air temperature for initialization; there

was no valid set temperature when the O2 trim control curves

were set

For temp-compensated start modes (see parameter

Startmode ), an ambient air temperature must be read

during commissioning. Check parameter Adjust.

Temp O2 to see if a valid reading was taken. If not,

use a non temp-compensated start mode or attach an

ambient air sensor and recommission a point on the O2

control curve.

07

O2 controller

operation locking

time for QGO21

too short

The QGO21 requires a longer waiting time than the QGO20

when entering into operation.

Adjust parameter NumberTauSuspend to 40.

08

during O2

controller

initialization

The O2 controller could not be initialized correctly after entering

into operation because the O2 value was too high (greater than

approx. 13%)

Check for an O2 sensor malfunction. Check for false

air in the stack. Increase startup locking time

(NumberTauSuspend ).

Fault with Base Unit (LMV5) or Connected Components

F3 LMV5

Section 7 Page 59 SCC Inc.

Loading...

Loading...