Technical Instructions LMV Series

Document No. LV5-800

0

Appendix A Page 22 SCC Inc.

Pilot Valve Proving (continued)

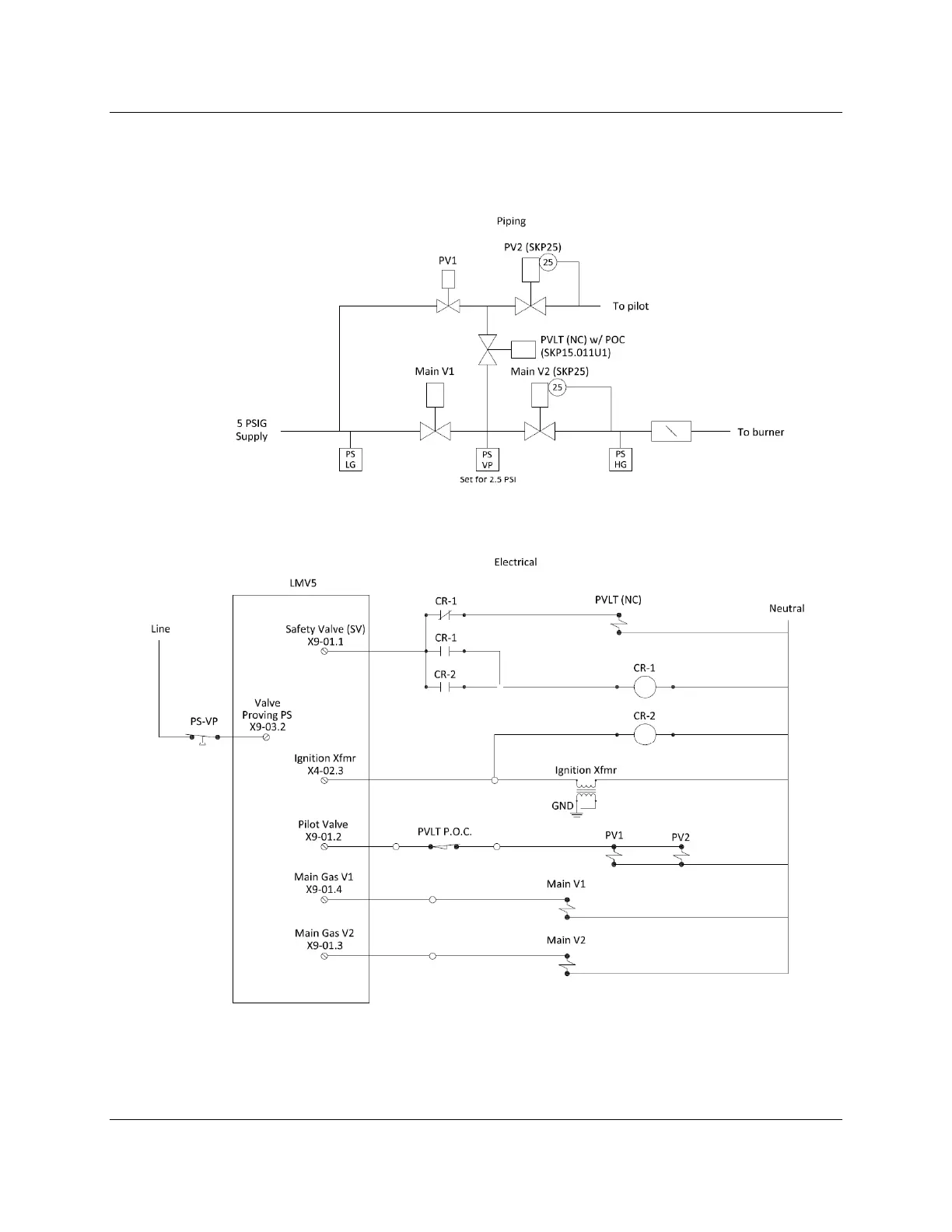

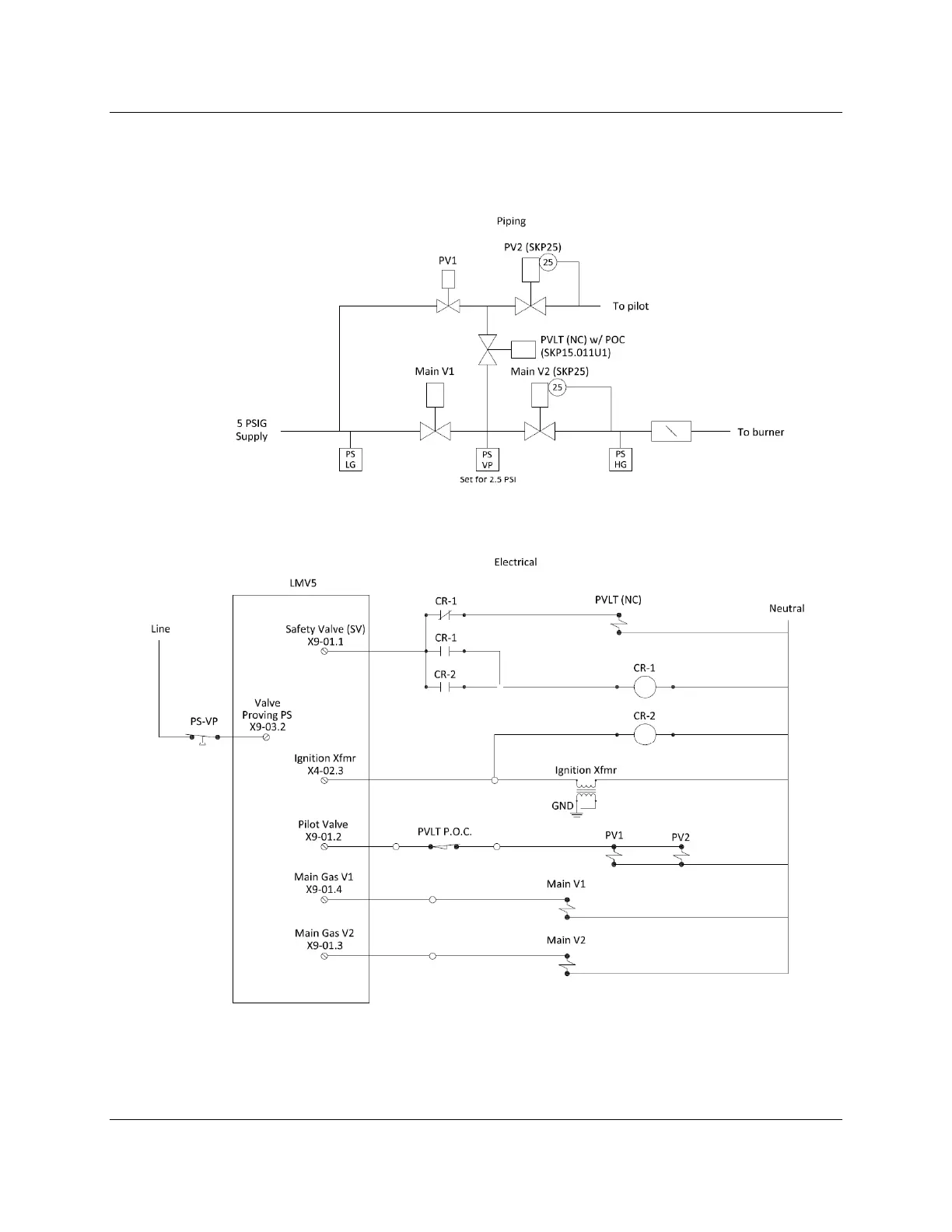

Option 1: On Startup with SKP25

’s on both the Pilot and Main Gas Trains

Figure 9: Option 1 Piping and Electrical Schematics

Loading...

Loading...