You will find additional information about making these settings in the following document:

References

Universal/Turning/Milling/Grinding Operating Manual

● Section "Machining a workpiece" > "Settings for Automatic mode mode"

● Section "Machining a workpiece" > "Editing a program" > "Settings for the editor"

Switching on the time recording

To use the function, the following channel machine data must be so set in all channels, even

if the machining time recording is not activated for all channels:

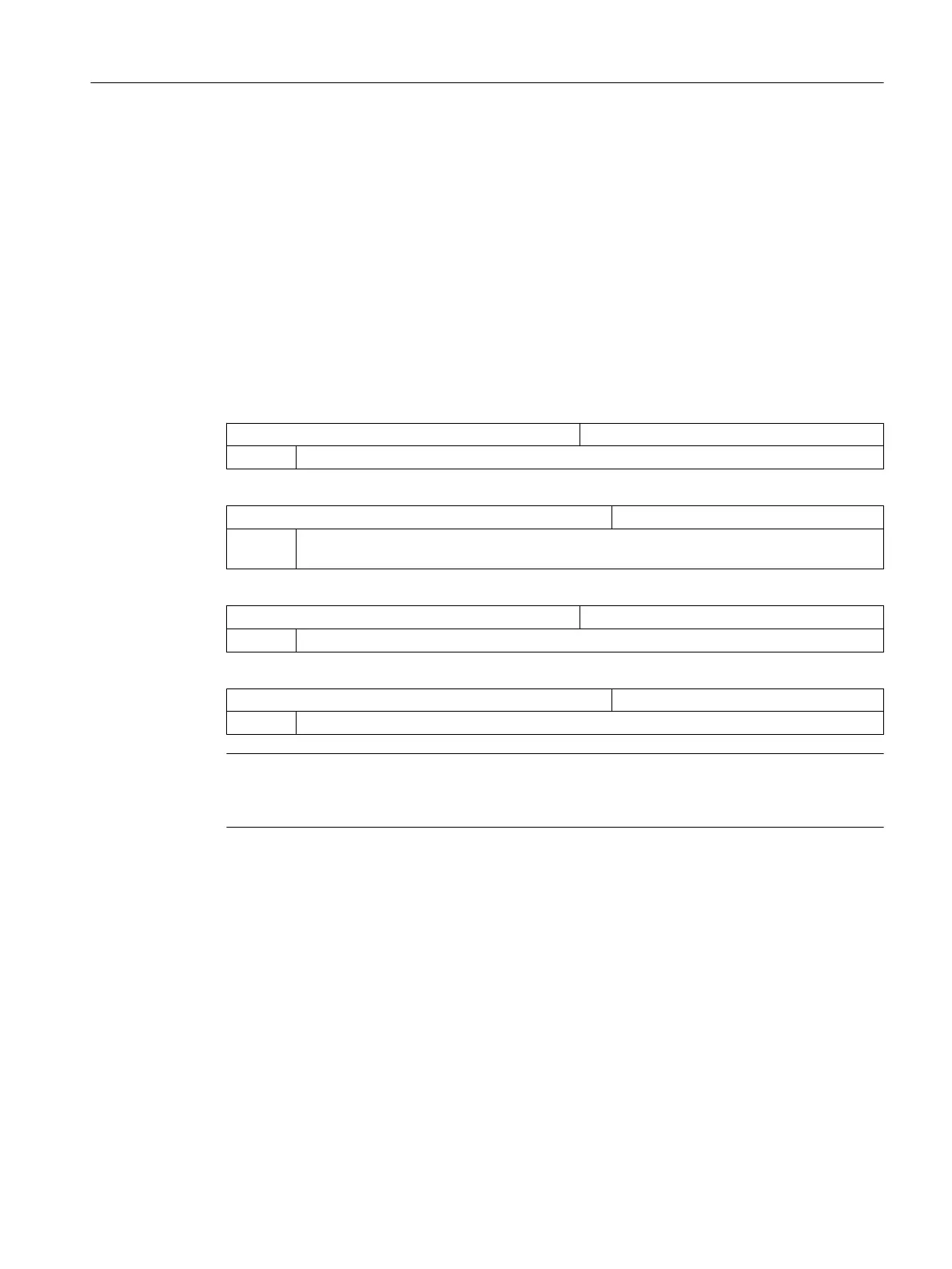

MD18370 $MN_MM_PROTOC_NUM_FILES[1] Maximum number of log files

= 2 For OEM applications

MD18371 $MN_MM_PROTOC_NUM_ETPD_STD_LIST[1] Number of standard ETPD data lists

= 6 Number of standard data lists in the OPI module ETPD that are needed for Trace system

functions.

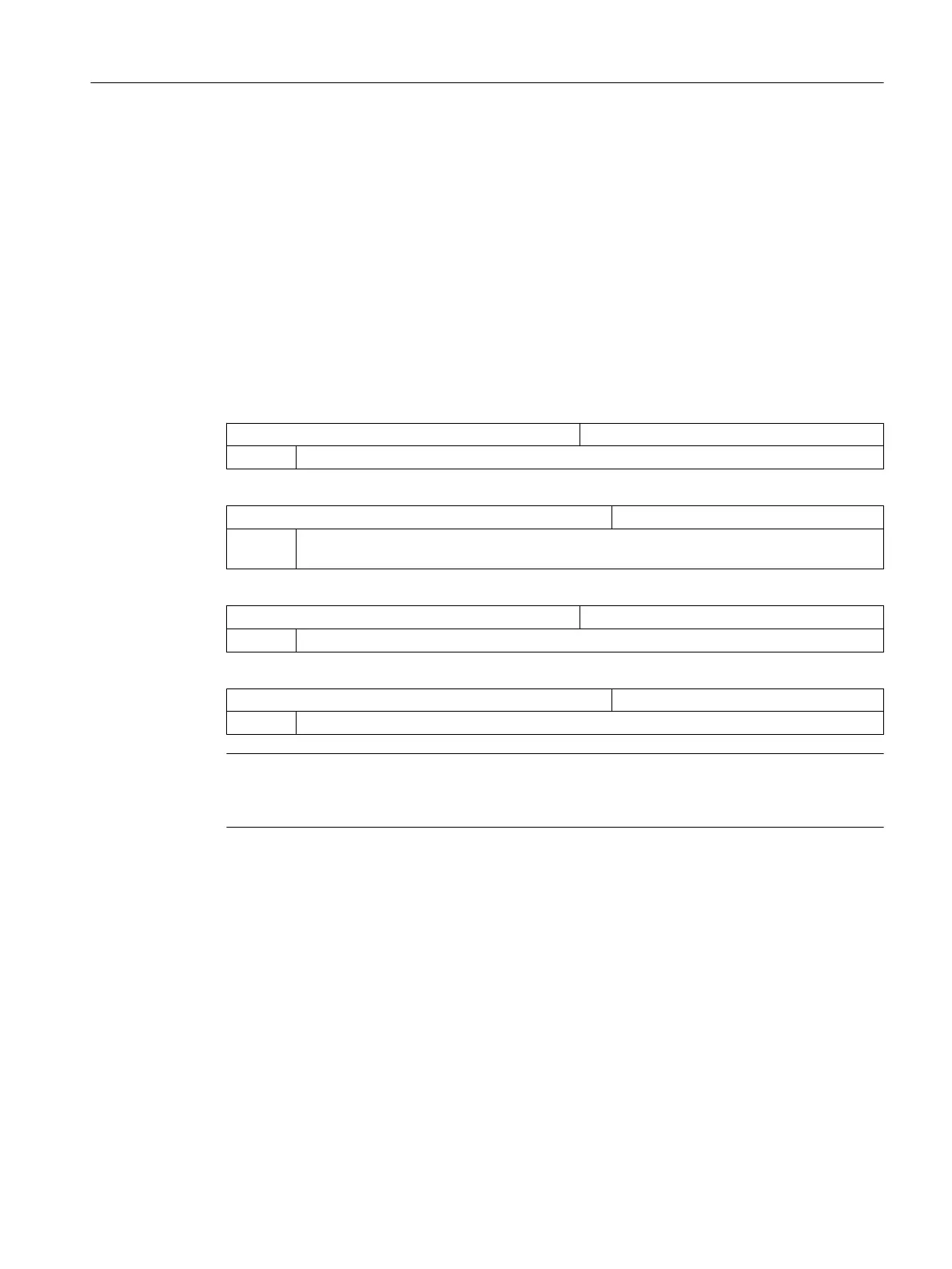

MD28300 $MC_MM_PROTOC_USER_ACTIVE[1] Activate logging for one user

= 1 For system functions

MD28302 $MC_MM_PROTOC_NUM_ETP_STD_TYP[1] Number of ETP standard event types

= 5 Number of standard event types in the OPI module ETP that are needed

Note

Machine data MD18370, MD18371, and MD28302 are still valid for machining time recording

when they are assigned higher values.

Customizing the "Machine" operating area

8.13 Activate machining time recording

SINUMERIK Operate (IM9)

Commissioning Manual, 12/2017, 6FC5397-1DP40-6BA1 135

Loading...

Loading...