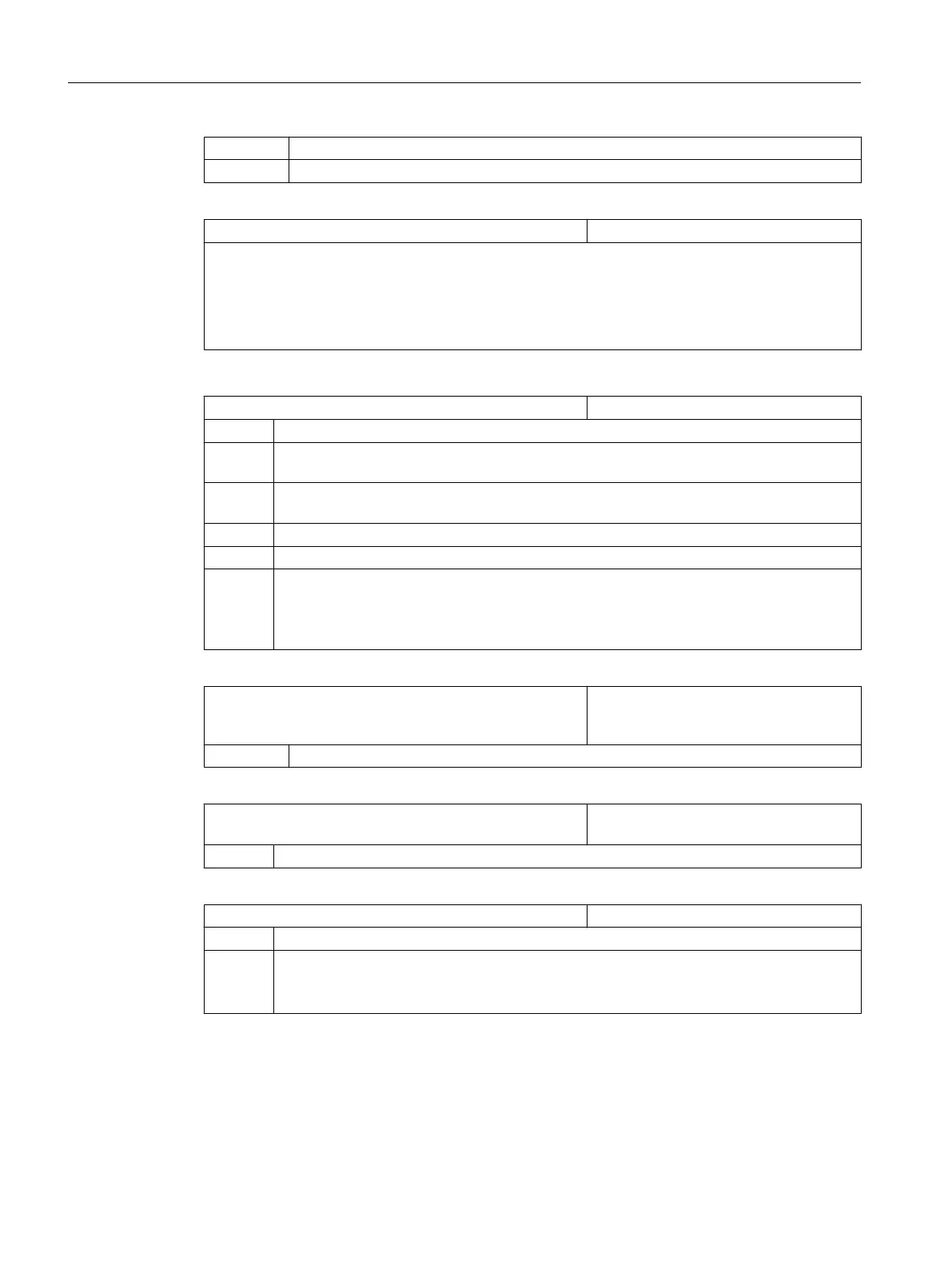

Bit 3 = 1 Tool reference ($P_TOOLFRAME)

Bit 4 = 1 Workpiece reference ($P_WPFRAME)

MD28085 $MC_MM_LINK_TOA_UNIT Assigning a TO unit to a channel (SRAM)

If several channels are set-up, then the following can be set in the machine data:

Assignment of the TO units (tools and orientable tool holders) to the NC channel. One TO unit can be

assigned to several channels.

- OR -

Each NC channel is assigned one TO unit.

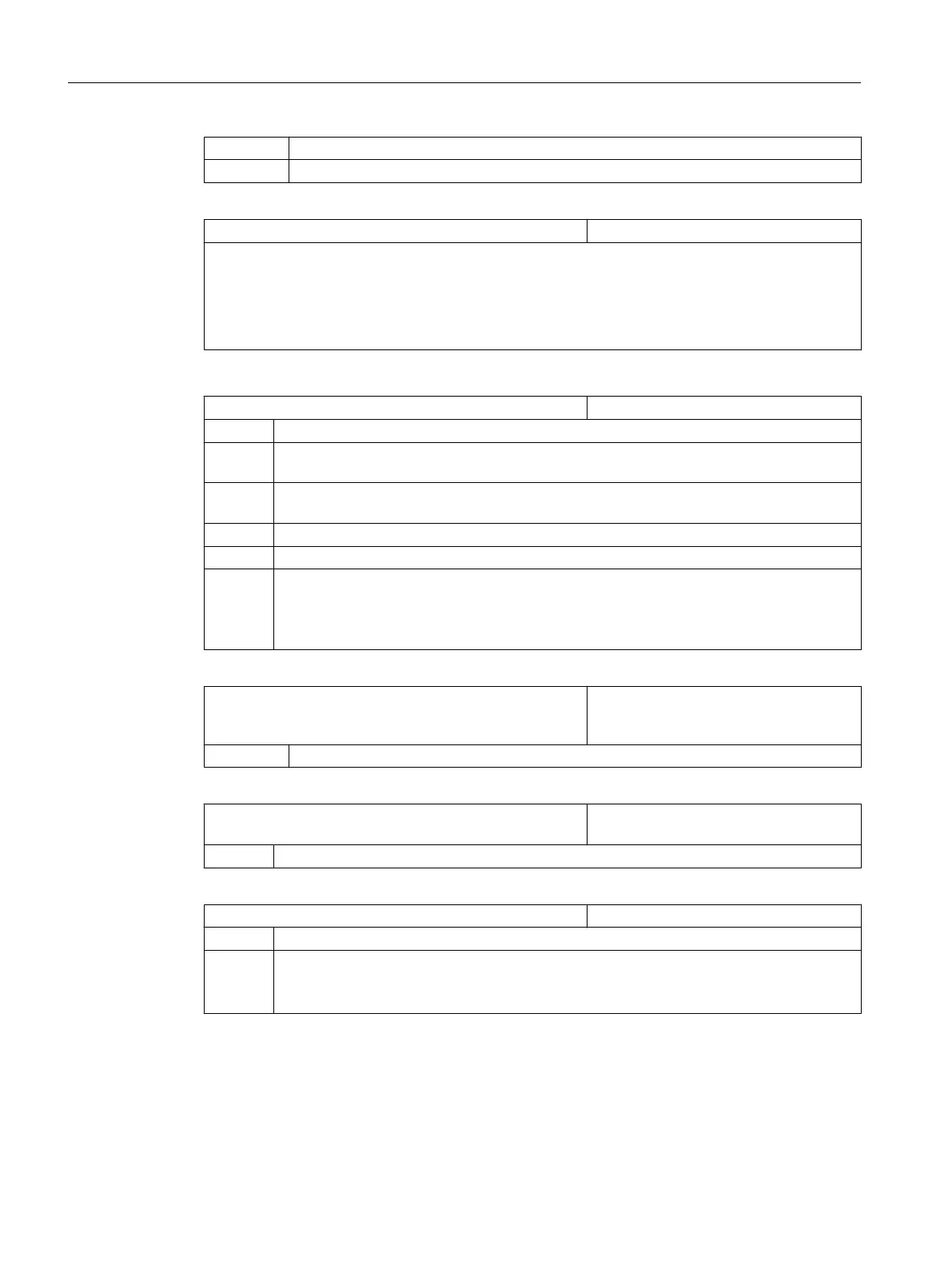

Axial machine data for the modulo rotary axes of the swivel data set

MD30455 $MA_MISC_FUNCTION_MASK Axis functions

Bit 0 Modulo rotary axis programming

= 0 Programmed positions must be in the modulo range, otherwise an alarm is triggered (e.g. 0

to 359.999 degrees).

= 1 When positions are programmed outside of the modulo range, no alarms are signaled. The

position is modulo converted internally (e.g. -180 to +180 degrees).

Bit 2 Positioning, rotary axis

= 0 As programmed

= 1 Along the shortest path

Application: With the setting bit 2=1, the rotary axis C travels along the shortest path for G90

with DC. For further information, refer to Chapter "Manufacturer cycle CUST_800.SPF

(Page 589)".

MD32010 $MA_JOG_VELO_RAPID[AX]

AX = axis name

Rapid traverse in JOG

Rotary and machine axes that should trav‐

el for swiveling in JOG.

= 10000 Rapid traverse in JOG mode for swivelling in JOG

SD42980 $SC_TOFRAME_MODE Setting, frame definition for TOROT, PA‐

ROT

= 2000 Swivel (default value)

SD42974 $SC_TOCARR_FINE_CORRECTION Fine offset TCARR (swivel data set)

= 0 No fine offset of the swivel data set vectors

= 1 Fine offset of the swivel data set vectors

The parameters of the swivel data set from $TC_CARR41[n] n…number of the swivel data

set and higher apply

Technologies and cycles

21.7 Swiveling

SINUMERIK Operate (IM9)

566 Commissioning Manual, 12/2017, 6FC5397-1DP40-6BA1

Loading...

Loading...