Do you have a question about the Siemens SENTRON PAC3200 and is the answer not in the manual?

Explains the manual's objective and intended audience for the SENTRON PAC3200.

Lists aids like table of contents, figures, and index to help navigate the manual.

Details the items included in the SENTRON PAC3200 package, such as the device and accessories.

Lists the files and software available on the SENTRON PAC CD.

Provides contact information for regional support, online services, and technical assistance.

Lists other relevant manuals for additional details on the SENTRON PAC3200 and related modules.

Covers general safety precautions, including DANGER warnings for high voltage and proper procedures.

Highlights key capabilities and specifications of the SENTRON PAC3200 Power Monitoring Device.

Details the device's capabilities for AC current and voltage measurements, including connection types.

Lists all measurable variables, their designations, units, and value ranges supported by the device.

Explains how the device acquires and displays power demand and the functionality of its energy counters.

Describes the device's support for 2 tariffs for integrated energy counters and tariff switching controls.

Details the function for monitoring up to 6 limit values, their combination, and display of violations.

Explains how the device handles counter values and data during power interruptions and restoration.

Describes the functions and configurations of the SENTRON PAC3200's multifunctional digital input and output.

Covers Ethernet connection, Modbus TCP support, and parameter settings for communication.

Details the available slot for optional expansion modules like PAC PROFIBUS DP.

Clarifies that rear slots for memory cards or batteries are not available or are blanked off.

Covers crucial aspects of operation planning, including mounting location, position, and ventilation requirements.

Provides instructions for checking the packaging and device for damage before installation.

Lists the necessary tools and additional accessories required for installing the SENTRON PAC3200.

Refers to the "Dimension drawings" chapter for detailed information on cutout, frame, and clearance dimensions.

Provides a step-by-step guide for installing the SENTRON PAC3200 into a switching panel.

Details the procedure and tools required for safely removing the SENTRON PAC3200 from its installation.

Emphasizes critical safety instructions, especially regarding dangerous high voltages and qualified personnel.

Explains connection designations for screw and ring lug terminals, including grounding and reference potential.

Guides the user on how to properly connect cables to both screw and ring lug terminals.

Illustrates various connection configurations for different system types and configurations.

Outlines the prerequisites and essential steps for successfully starting up the SENTRON PAC3200 device.

Details the procedure for connecting the device's power supply, including fuse protection and limit values.

Explains the process of setting essential operating parameters for the SENTRON PAC3200.

Covers setting the display language and phase labels for regional customization.

Details the configuration of basic parameters related to voltage and current inputs.

Guides on how to apply the correct measuring voltage, considering different power supply types and transformers.

Provides instructions for connecting current transformers and safety precautions related to current measurement.

Explains how to verify the accuracy of displayed measured values against the configured connection type.

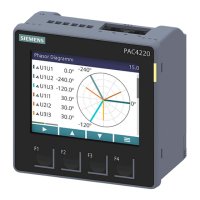

Describes the SENTRON PAC3200's physical interface, including displays, operator controls, and their functions.

Details how to navigate menus, select variables, and input data using the device's function keys.

Introduces the parameterization chapter, covering device settings and protection.

Explains how to configure various device settings through the operator interface, organized by groups.

Describes how to configure the PROFIBUS DP expansion module settings within the device.

Details the configuration settings for the PAC RS485 expansion module.

Covers switching password protection on/off, changing passwords, and procedures for lost passwords.

Provides instructions for cleaning the device display and keypad, with a caution against using detergents.

Outlines the procedure for returning faulty devices for repair or replacement, noting warranty implications.

Advises on the proper disposal and recycling of the device according to local laws and regulations.

Presents comprehensive technical specifications of the SENTRON PAC3200, including device configuration, inputs, accuracy, and power supply.

Explains the various symbols and labels found on the SENTRON PAC3200 housing and their meanings.

Provides detailed graphical representations of the device's physical dimensions and panel cutout requirements.

Lists the CE and UL marks, indicating compliance with relevant directives and standards.

Provides a form for users to submit feedback on errors or suggestions for manual improvements.

Explains the risks of electrostatic discharge to electronic components and outlines necessary protective measures.

Provides a comprehensive list of abbreviations used throughout the manual and their meanings.

Defines the term "Bus" in the context of communication systems.

Defines a "Bus system" as nodes connected to a bus cable.

Explains the concept of "Diagnosis" in system monitoring, including error detection and visualization.

Defines PROFIBUS as a European process and fieldbus standard for automation systems.

Explains that each PROFIBUS node has a unique address for identification.

| Operating Temperature | -10°C to +55°C |

|---|---|

| Storage Temperature | -25°C to +70°C |

| Mounting | DIN rail |

| Device Type | Power Monitoring Device |

| Measuring Category | CAT III |

| Protection Class | IP40 (front), IP20 (terminals) |

| Weight | Approx. 0.5 kg |

| Measurement Accuracy | Class 0.5S (Active Energy) |

| Display | LCD |

| Current Measurement Range | 1 A to 5 A |

| Frequency Measurement Range | 45 Hz to 65 Hz |

| Communication Interfaces | RS485, Modbus RTU |

| Power Supply | AC or DC |

| Supply Voltage | 85-264V AC/DC |

| Accuracy Active Energy | Class 0.5S |

| Accuracy Reactive Energy | Class 2 |

| Dimensions | 96 x 96 mm |

Loading...

Loading...