Glossary

Distributed I/O system

System Manual, 12/2016, A5E03576849-AG

297

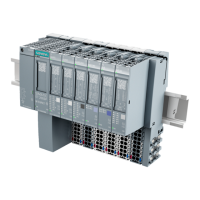

ET 200SP modules with integrated safety functions that can be used for safety-related

operation (safety mode).

Fail-safe systems (F-systems) remain in a safe state or immediately assume another safe

state as soon as particular failures occur.

The maximum fault reaction time of an F-system defines the interval between the occurrence

of any fault and a safe reaction at all affected fail-safe outputs.

The maximum fault reaction time defines the interval between the

occurrence of any fault in any → F-I/O and a safe response at the relevant fail-safe output.

The maximum fault reaction time defines the interval between the

occurrence of the fault and the safe reaction on the backplane bus.

The maximum fault reaction time defines the interval between the

occurrence of the fault and the safe reaction at the digital output.

The fault tolerance time of a process is the time a process can be left unattended without risk

to life and limb of the operating personnel, or damage to the environment.

Any type of F-system control is tolerated within this fault tolerance time, i.e. the → F-system

can control its processes incorrectly or even not at all. The fault tolerance time depends on

the type of process and must be determined on a case-by-case basis.

An F-CPU is a central processing unit with fail-safe capability that is permitted for use in

SIMATIC Safety. A standard user program can also be run on the F-CPU.

Collective name for fail-safe inputs and outputs available in SIMATIC S7 for integration into

the SIMATIC Safety F-system. Available F-I/O modules:

● Fail-safe I/O module for ET 200eco

● Fail-safe signal modules S7-300 (F-SMs)

● Fail-safe modules for ET 200S

● Fail-safe modules for ET 200SP

● Fail-safe DP standard slaves

● Fail-safe PA field devices

● Fail-safe IO devices

Loading...

Loading...