Glossary

Distributed I/O system

System Manual, 12/2016, A5E03576849-AG

299

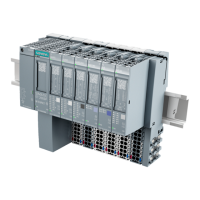

Module in the distributed I/O system. The interface module connects the distributed I/O

system via a fieldbus to the CPU (IO controller) and prepares the data for and from I/O

modules.

IO-Link is a point-to-point connection to conventional and intelligent sensors/actuators by

unshielded standard cables in proven 3-wire technology. IO-Link is downward compatible to

all DI/DQ sensors/actuators. Switching status channel and data channel are designed in

proven 24 V DC technology.

All the modules attached to a mounting rail.

Supply of modules like the interface module, power supply modules, I/O modules, and (if

applicable) sensors and actuators.

Device identification unique worldwide, which is already assigned to each PROFINET device

in the factory. Its 6 bytes are divided into 3 bytes for the manufacturer ID and 3 bytes for the

device ID (serial number). The MAC address is usually legible on the device.

Every industrial machine that falls under the scope of DIN EN 60204 Part 1 (VDE 0113,

Part 1) must be equipped with a main switch that disconnects all electrical equipment from

the network while cleaning, maintenance, and repair work is being carried out, as well as

during long periods of downtime. Usually a switch which can be operated by hand that is

stipulated for electrical or mechanical prevention of a hazard. The main switch can also

function as an EMERGENCY-OFF device.

The main switch must meet the following requirements:

● Externally accessible mechanical rotary lock.

● Only one OFF position and one ON position with allocated stops.

● Two positions labeled "0" and "I". 4th lockable OFF position.

● Cover for the power supply terminals to protect against accidental contact.

● The switching capacity must correspond to AC-23 for motor switches and AC-22 for load-

break switches (utilization category).

● Switch position displayed automatically.

Loading...

Loading...