Ff

02/92

Matching Module 4 for Absolute Encoders

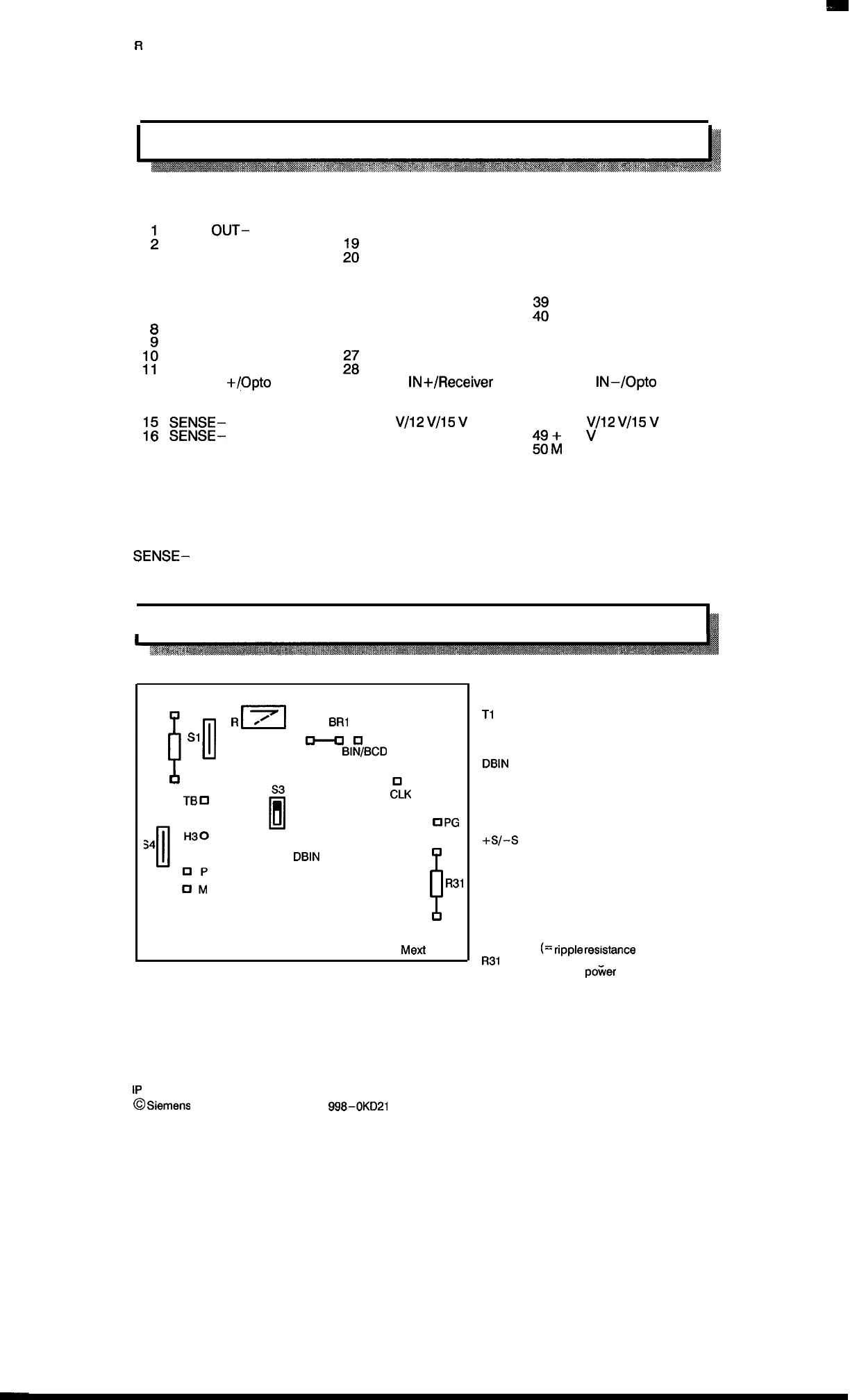

7.3.7 Connector Pin Assignment

Assignment of the sub D connector pins (channel 1 or 2)

;

3

4

5

6

7

8

1;

11

12

13

14

;:

17

Pins

LOOP

OUT–

18

34

35 LOOP OUT+

;:

36

21

22

23

24

25

26

:;

LOOP IN +/Opto coupler

29 LOOP iN+/Receiver

LOOP IN –/Receiver

30 SENSE+

31

37

38

::

41

42

43

44

45 LOOP IN–/Opto coupler

46

47

SENSE–

32 -t- 5

VI12

VI15

v 48 -f- 5

VI12

VI15

V

SENSE– 33 M

:4

;

24

V

Output

M

15/1 6 as well as pins 32/48 and pins 17/33/50 are parallel and can be used alternatively.

LOOP OUT = Clock pulse group output

LOOP IN

= Data input

SENSE+

= Sense(+) output for control of encoder power supply

SENSE–

= Sense(–) output for control of encoder power supply

I

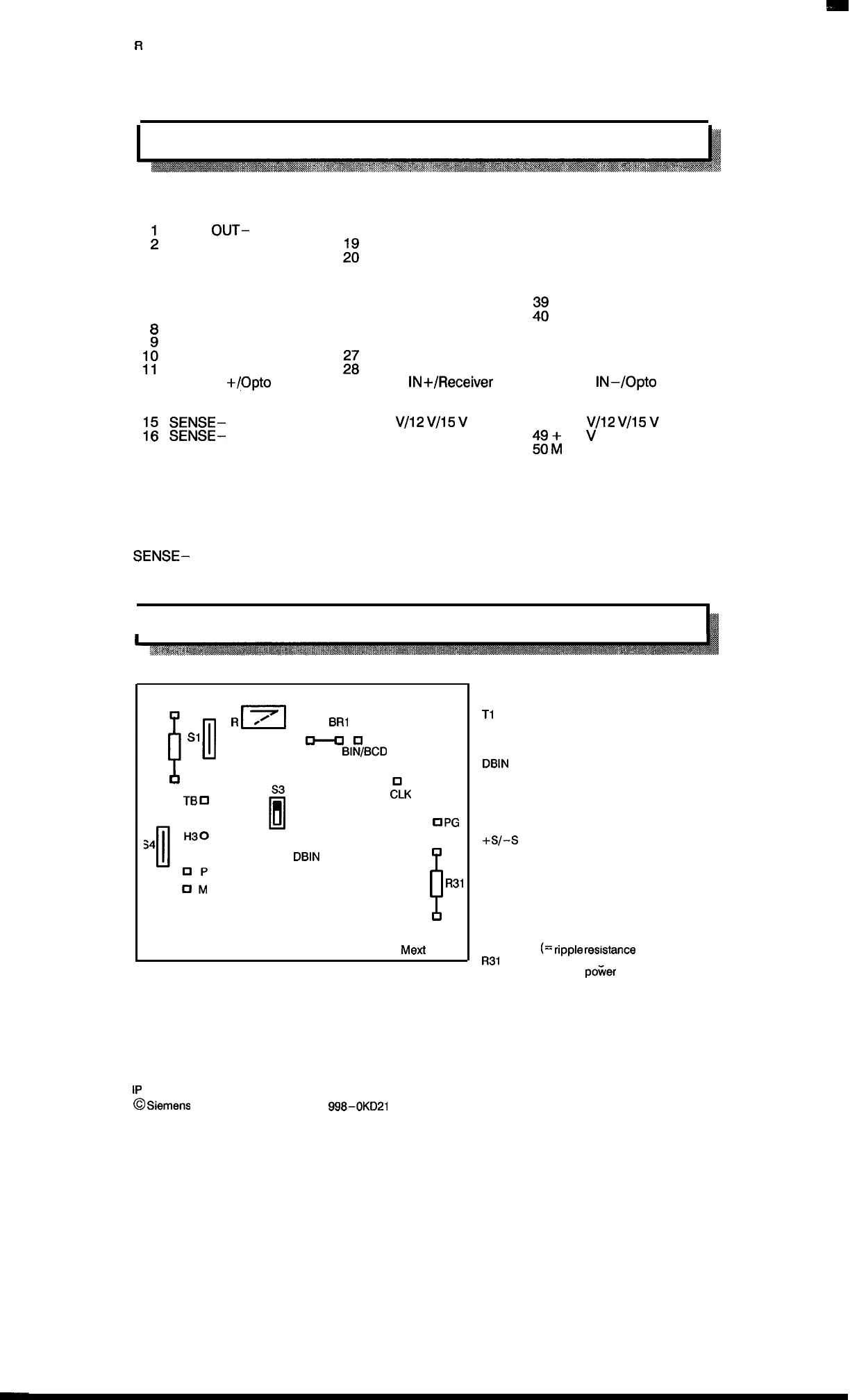

7.3.8 Layout

‘b

S2

T1

~11

o

n

❑

R

~

BR1

S1

R2

~n

Gray

BIN/BCD

b

H20

TBCI

UM

S5

El

— .2

—

.1

❑

DBIN

FLK

UPG

❑ +s

b

R31

/l

cl-s

Mexl

❑

TB =

T1

=

CLK =

DBIN

=

P=

M=

PG =

+s/-s

=

HI =

H2 =

H3 =

R2 =

R31

=

Measuring point for clock pulse

groups to the encoder

Measuring point for clock pulse

from the basic module

Measuring point preprogrammed

clock pulse

Measuring point after gray

binary conversion

Measuring point 5 V supply

M–potential (ground)

Measuring point configured

encoder supply

Measuring points for sense

voltages

LED indicates: Enable for

transmitting clock pulse groups

LED indicates: If continuously lit

the input signal is missing.

Data flow via opto coupler is

available

Conditioning resistance

(=

ripple

res@ance

of cable)

Conditioning resistance for

encoder poker supply

The layout shows the position of the configurable elements, jumpers, and switches.

1P

241 Equipment Manual

@

Siemens AG 1989, Order No.: 6ES5

998-0KD21

7 – 13

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...