6

6.2 Positioning mode (P0700 = 3, from SW 2.1)

6-401

Siemens AG 2005 All Rights Reserved

SIMODRIVE 611 universal Description of Functions (FBU) – 04.05 Edition

6.2.8 Parameter overview for referencing/adjustments

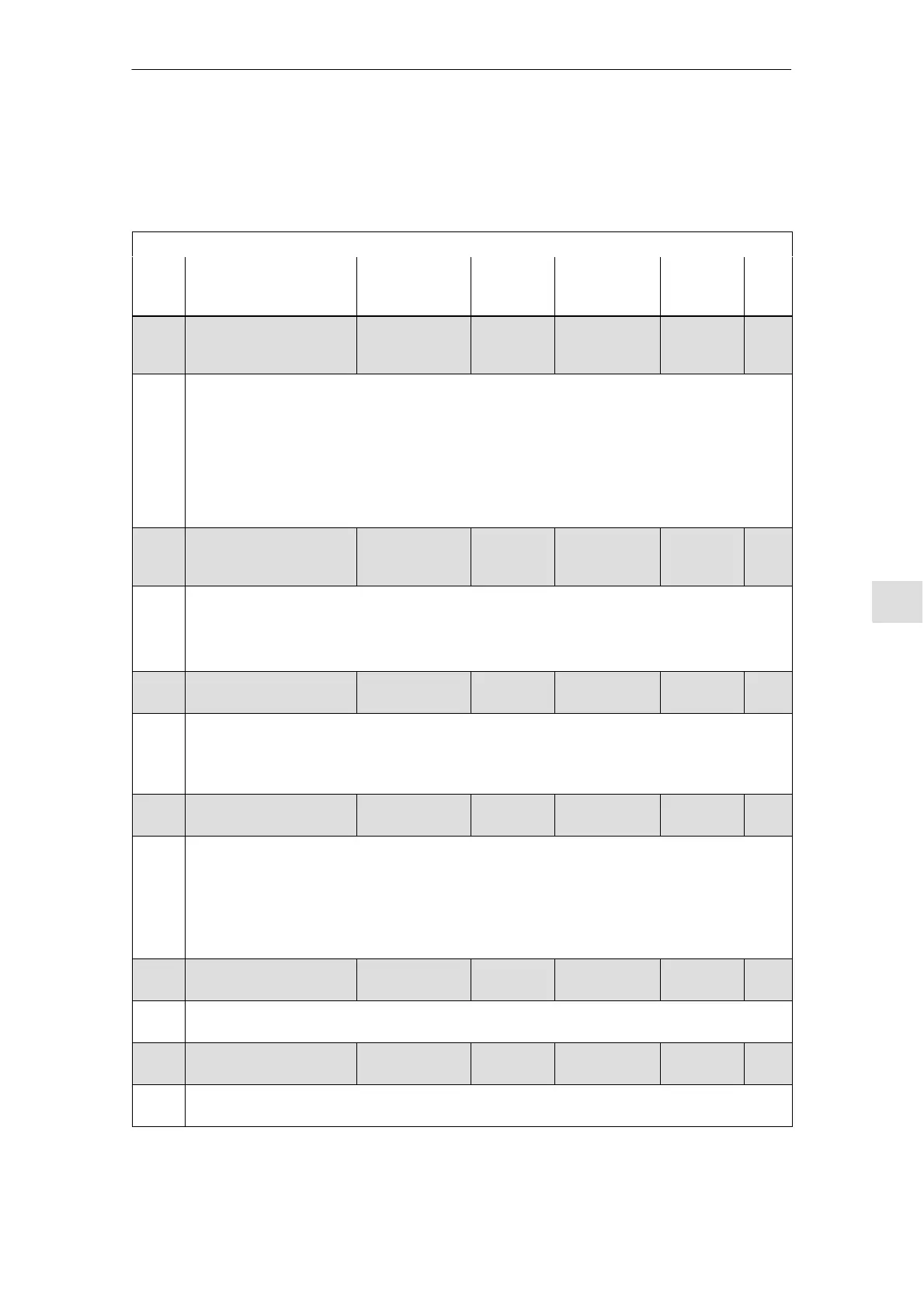

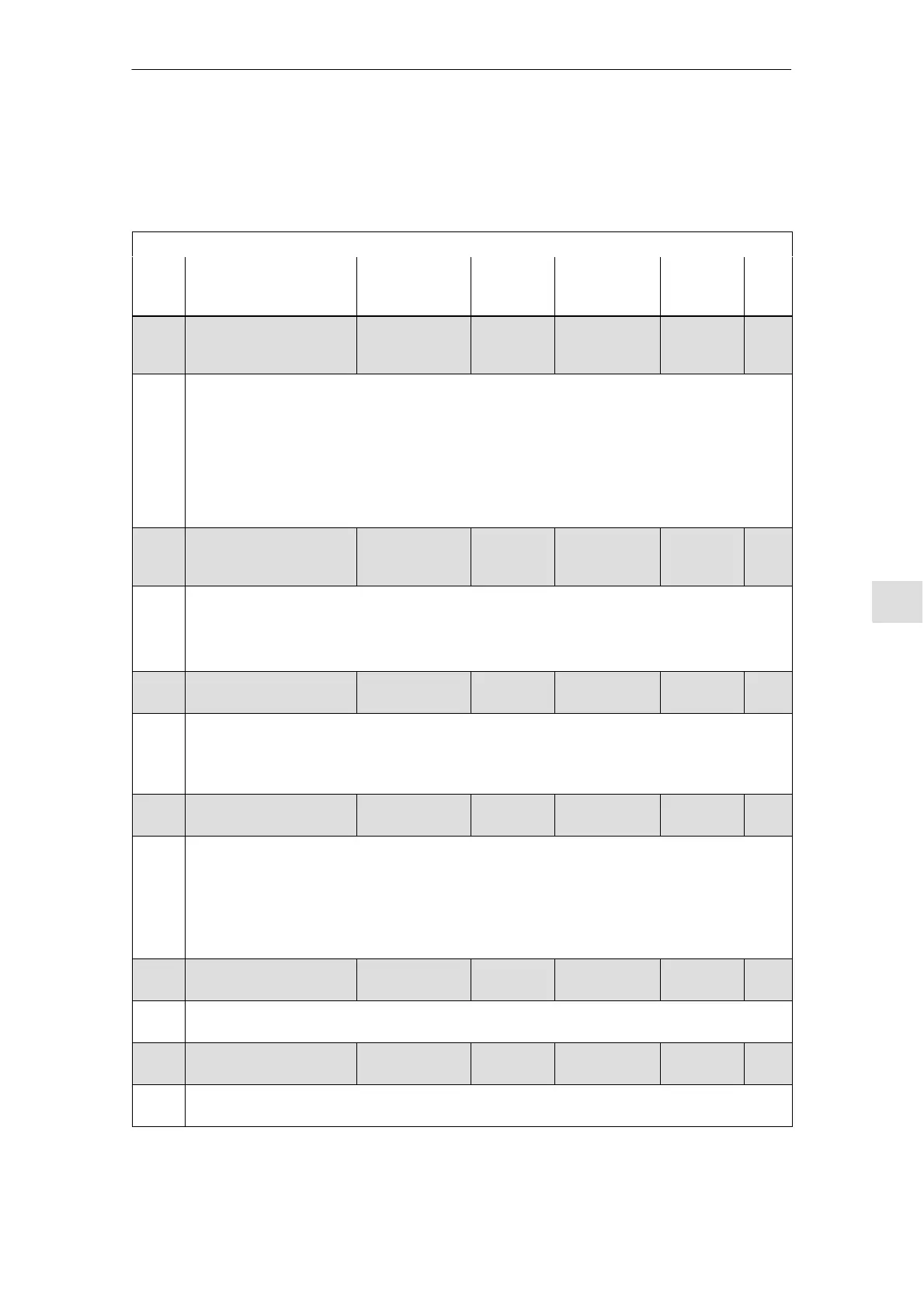

Table 6-35 Parameter overview when referencing/adjusting

Parameters

No. Name Min. Standard Max. Units Ef-

fec-

tive

0160 Reference point

coordinate

–200 000 000 0 200 000 000 MSR Im-

medi-

ately

The parameter defines the position value which is set, as actual axis position, after referencing

or adjusting.

Incremental measuring system

After the reference point has been reached, the drive accepts the position value in this pa-

rameter as the current axis position.

Absolute value encoders

When adjusting the encoder, the position value in this parameter is set as the actual axis

position. The difference to the actual encoder actual value is entered into P0162.

0161 Stopping at marks

(from SW 8.3)

0 0 1 – Im-

medi-

ately

...defines the behavior when stopping at marks.

0 Reference point approach is not interrupted at marks (standard)

1 Reference point approach remains stationary, if the first zero mark or, for distance–coded

measuring systems, the second zero mark was found.

0162 Reference point

offset

–200 000 000 –2 000 200 000 000 MSR PrgE

Incremental measuring system

After the reference zero pulse has been identified, the axis is moved through this distance.

The axis has reached the reference point of this position, and accepts the reference point

coordinate (P0160) as new actual value.

0163 Reference point

approach velocity

1 000 5 000 000 2 000 000 000 c*MSR/min PrgE

The axis moves with this velocity towards the reference cam after the reference point approach

has been started.

The velocity must be set, so that after the reference cam has been reached, and braking, the

following conditions must be fulfilled:

The axis must come to a standstill at the reference cam

It is not permissible that the hardware limit switch is reached when braking

0164 Reference point

shutdown velocity

1 000 300 000 2 000 000 000 c*MSR/min PrgE

The axis moves with this velocity between identifying the reference cam and synchronizing with

the first zero pulse (reference zero pulse).

0165 Reference point

entry velocity

1 000 300 000 2 000 000 000 c*MSR/min PrgE

The axis traverses with this velocity between synchronizing with the first zero pulse (reference

zero pulse) and reaching the reference point.

6 Description of the Functions

04.05

Loading...

Loading...