Transformations

6.8 Kinematic transformation

Job planning

370 Programming Manual, 07/2010, 6FC5398-2BP40-0BA0

With additional linear axis and groove wall offset (transformation type 514):

On a machine with a second linear axis, this transformation variant makes use of redun-

dancy in order to perform improved tool compensation. The following conditions then apply

to the second linear axis:

● a smaller working area and

● the second linear axis should not be used for the travel through the parts program.

Certain machine data settings are assumed for the parts program and the assignment of the

corresponding axes in the BCS or MCS, see

References

/FB2/ Function Manual Extended Functions; Kinematic Transformations (M1)

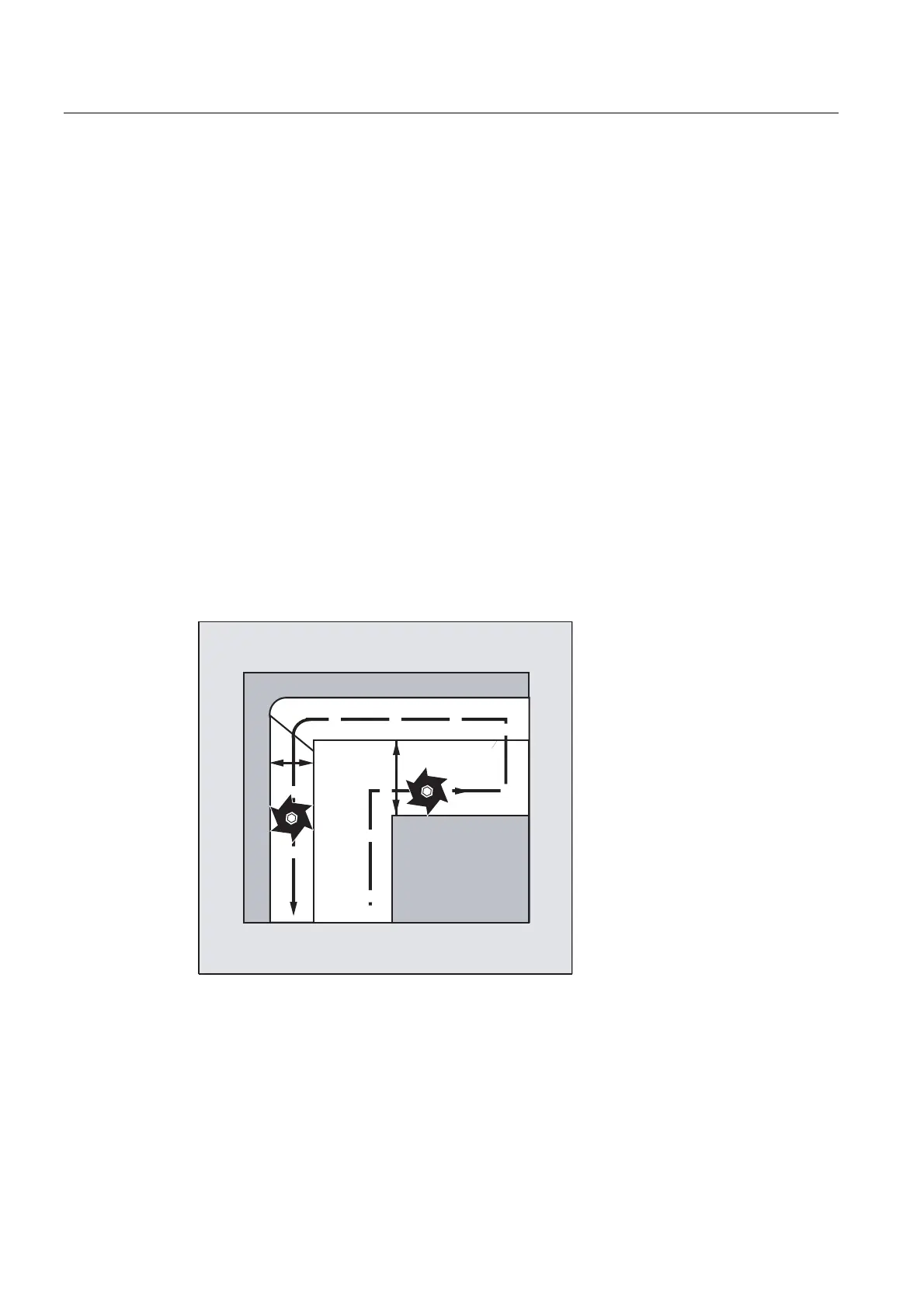

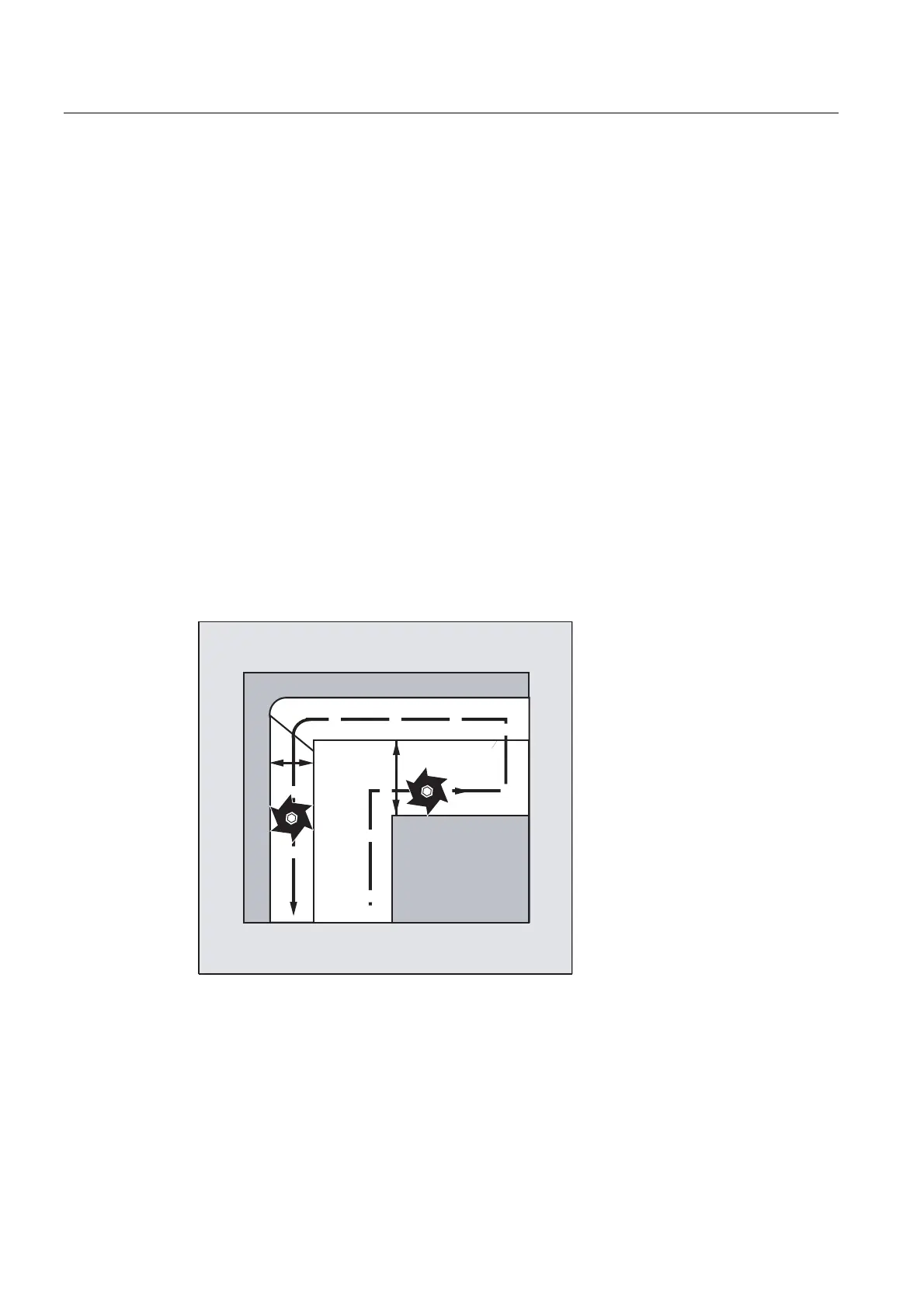

Offset contour normal OFFN (transformation type 513)

To mill grooves with TRACYL, the following is programmed:

● groove center line in the part program,

● half the groove width programmed using

OFFN.

To avoid damage to the groove side

OFFN acts only when the tool radius compensation is

active. Furthermore, OFFN should also be >= the tool radius to avoid damage occurring to

the opposite side of the groove.

2))1

SURJUDPPHG

FRQWRXU

Loading...

Loading...