Tool offsets

7.8 Tool holder kinematics

Job planning

436 Programming Manual, 07/2010, 6FC5398-2BP40-0BA0

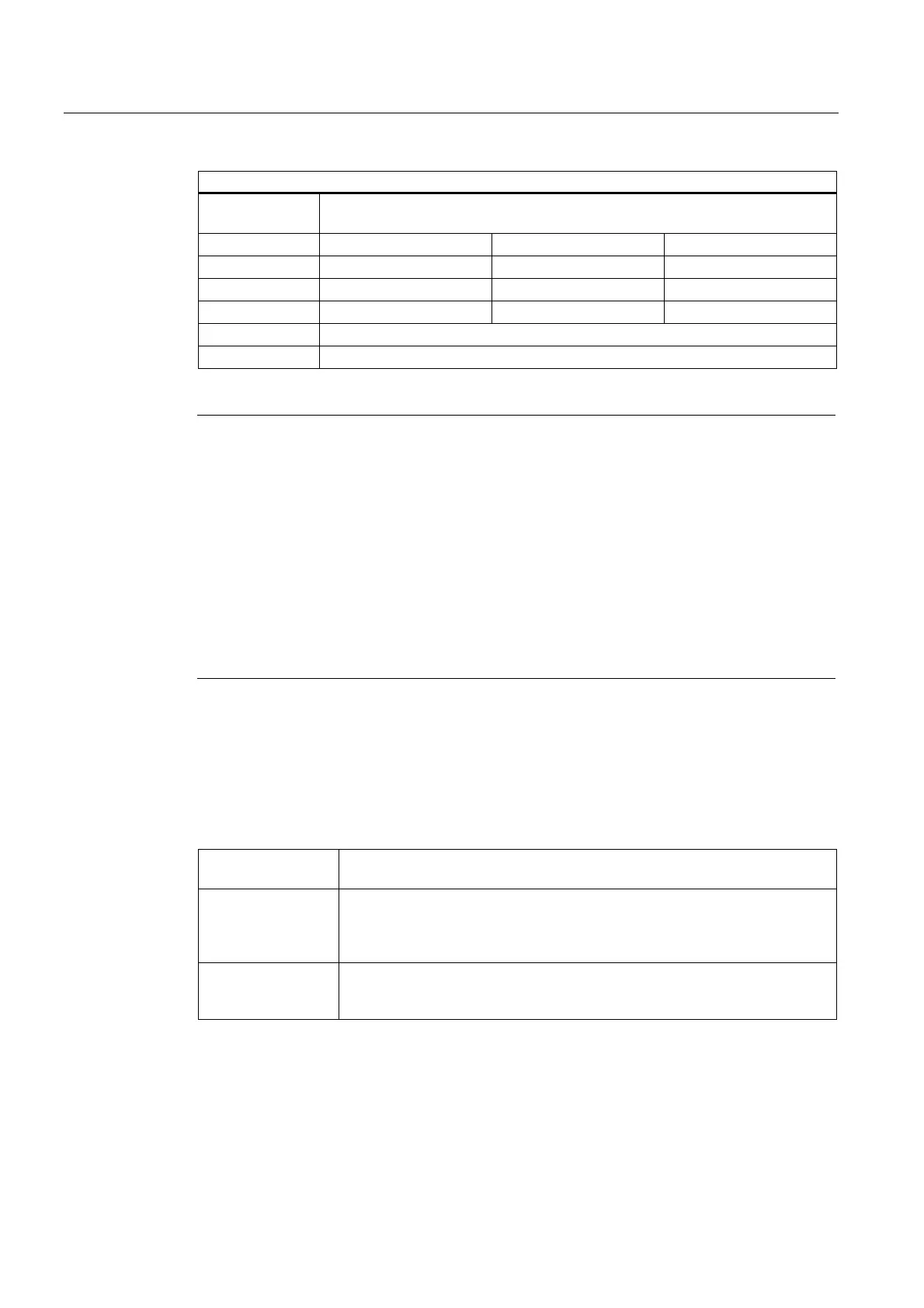

Extensions of the system variables for orientable toolholders

Fine

offset

Parameters that can be added to the values

in the basic parameters.

l

1

Offset vector $TC_CARR41[m] $TC_CARR42[m] $TC_CARR43[m]

l

2

Offset vector $TC_CARR44[m] $TC_CARR45[m] $TC_CARR46[m]

l

3

Offset vector $TC_CARR55[m] $TC_CARR56[m] $TC_CARR57[m]

l

4

Offset vector $TC_CARR58[m] $TC_CARR59[m] $TC_CARR60[m]

v

1

rotary axis $TC_CARR64[m]

v

2

rotary axis $TC_CARR65[m]

Note

Explanations of parameters

"m" specifies the number of the toolholder to be programmed.

$TC_CARR47 to $TC_CARR54 and $TC_CARR61 to $TC_CARR63 are not defined and produce an

alarm if read or write access is attempted.

The start/endpoints of the distance vectors on the axes can be freely selected. The rotation

angles

α

1

, α

2

about the two axes are defined in the initial state of the toolholder by 0°. In this

way, the kinematics of a toolholder can be programmed for any number of possibilities.

Toolholders with only one or no rotary axis at all can be described by setting the direction

vectors of one or both rotary axes to zero.

With a toolholder without rotary axis the distance vectors act as additional tool compensa-

tions whose components cannot be affected by a change of machining plane (

G17 to G19).

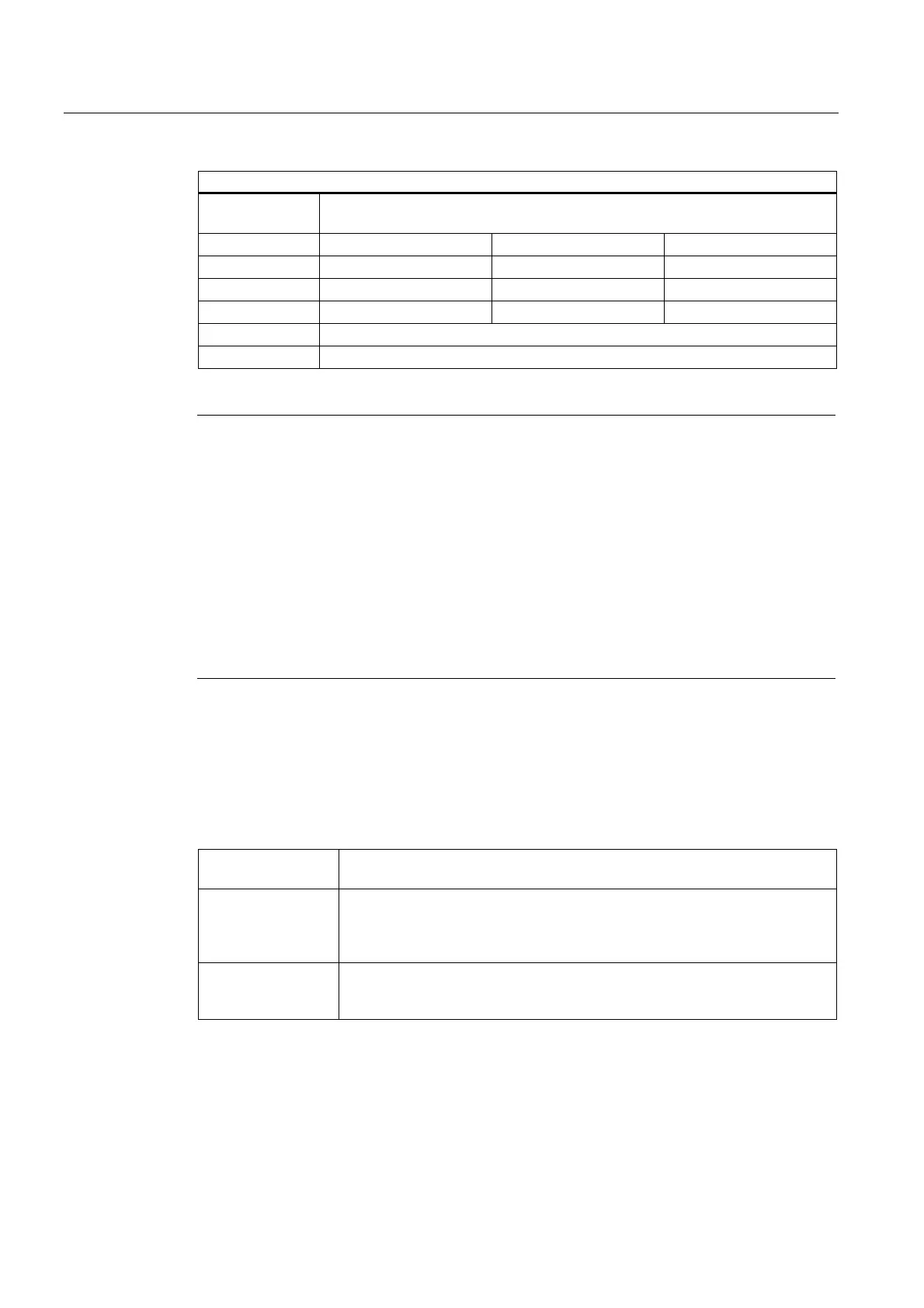

Parameter extensions

Parameters of the rotary axes

The system variables have been extended by the entries $TC_CARR24[m] to

$TC_CARR33[m] and described as follows:

Offset of

rotary axes v

1

, v

2

Changing the position of the rotary axis v

1

or v

2

for the initial setting of the

oriented toolholder.

The angle

offset/angle

increment of the

rotary axes v

1

, v

2

The offset or the angle increment of the Hirth tooth system of the rotary axes

v

1

and v

2

. Programmed or calculated angle is rounded up to the next value

that results from phi = s + n * d when n is an integer.

The minimum and

maximum position of

the rotary axes v

1

, v

2

The minimum and maximum position of the rotary axis limit angle (software

limit) of the rotary axes v1 and v2.

Parameters for the user

$TC_CARR34 to $TC_CARR40 contain parameters that are freely available to users and up

to SW 6.4 were as standard, not further evaluated within the NCK or had no significance.

Loading...

Loading...