Tool offsets

7.8 Tool holder kinematics

Job planning

Programming Manual, 07/2010, 6FC5398-2BP40-0BA0

437

Fine offset parameters

$TC_CARR41 to $TC_CARR65 include fine offset parameters that can be added to the

values in the basis parameters. The fine offset value assigned to a basic parameter is

obtained when the value 40 is added to the parameter number.

Example

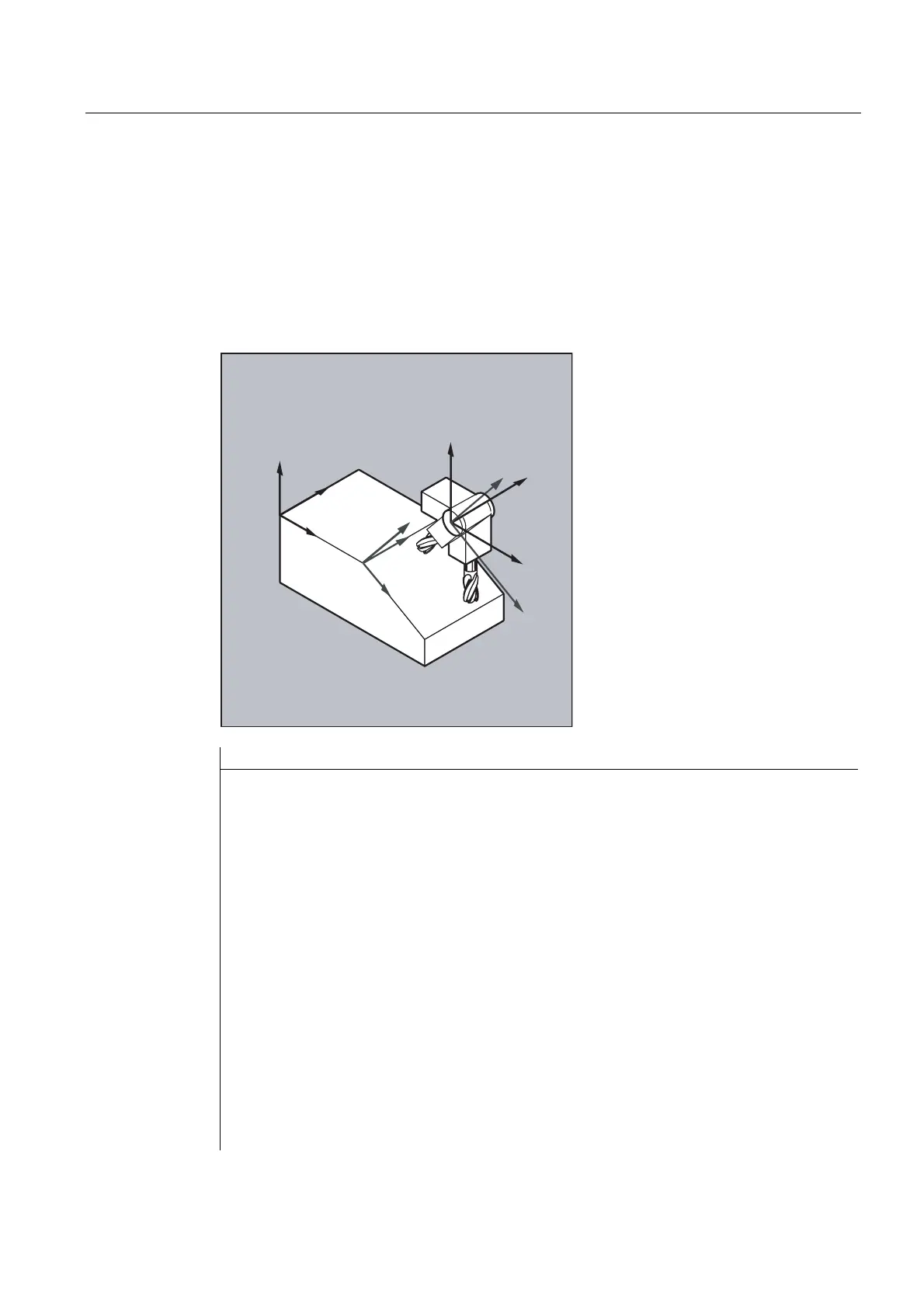

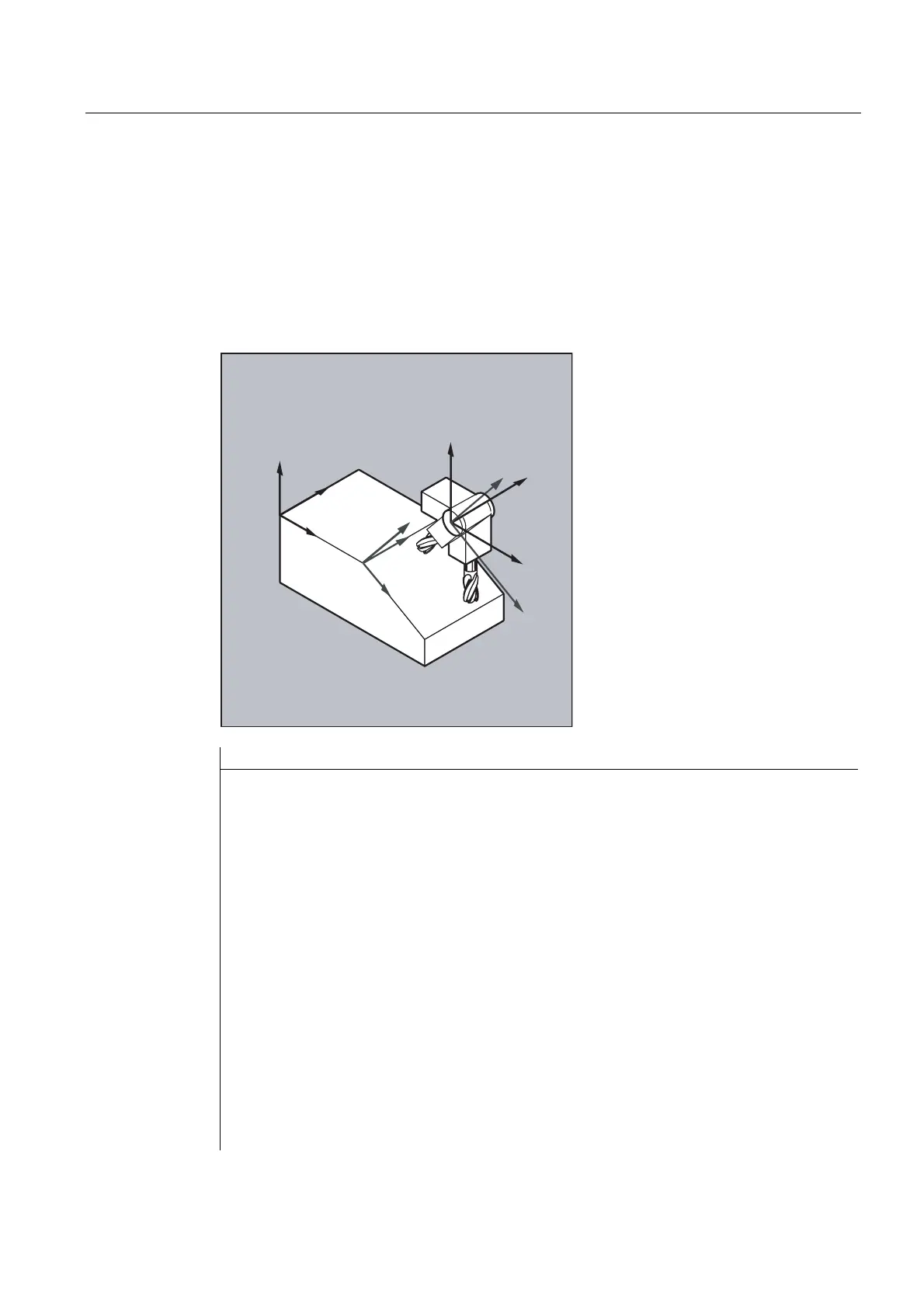

The toolholder used in the following example can be fully described by a rotation around the

Y axis.

=

;

;

<

]

=

;

;

<

<

]

Program code Comments

N10 $TC_CARR8[1]=1 ; Definition of the Y component of the

first rotary axis of toolholder 1.

N20 $TC_DP1[1,1] = 120 ; Definition of a shaft miller.

N30 $TC_DP3[1,1]=20 ; Definition of a shaft miller, 20 mm

long.

N40 $TC_DP6[1,1]=5 ; Definition of a shaft miller with 5 mm

radius.

N50 ROT Y37 ; Frame definition with 37° rotation

around the Y axis.

N60 X0 Y0 Z0 F10000 ; Approach starting position.

N70 G42 CUT2DF TCOFR TCARR=1 T1 D1 X10 ; Set radius compensation, tool length

compensation in rotated frame, select

toolholder 1, tool 1.

N80 X40 ; Perform machining under a rotation of

37°.

N90 Y40

N100 X0

N110 Y0

N120 M30

Loading...

Loading...