3 Functional description of the structure switches

3.9 Adaptation (S48)

Manual

114

SIPART DR21

C73000-B7476-C143-08

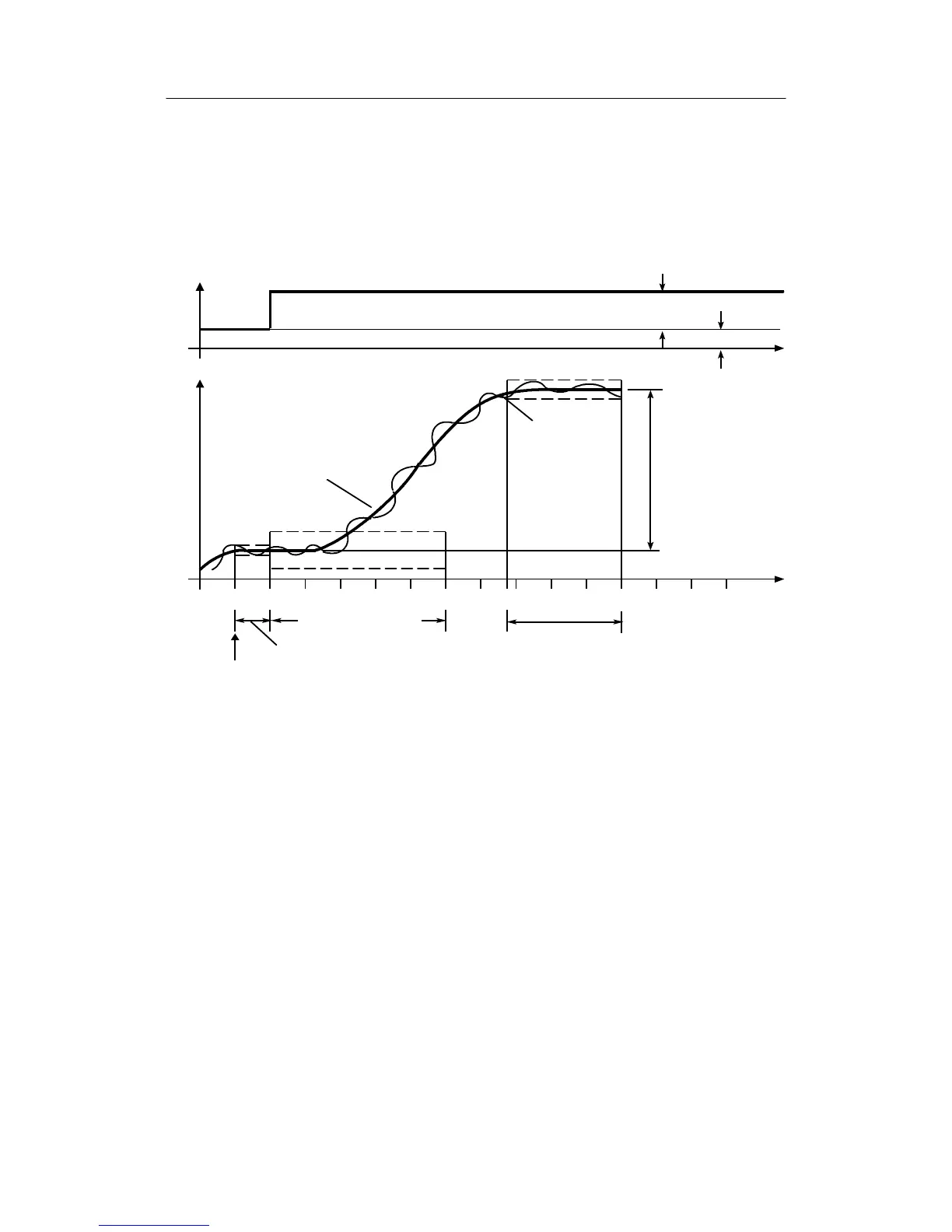

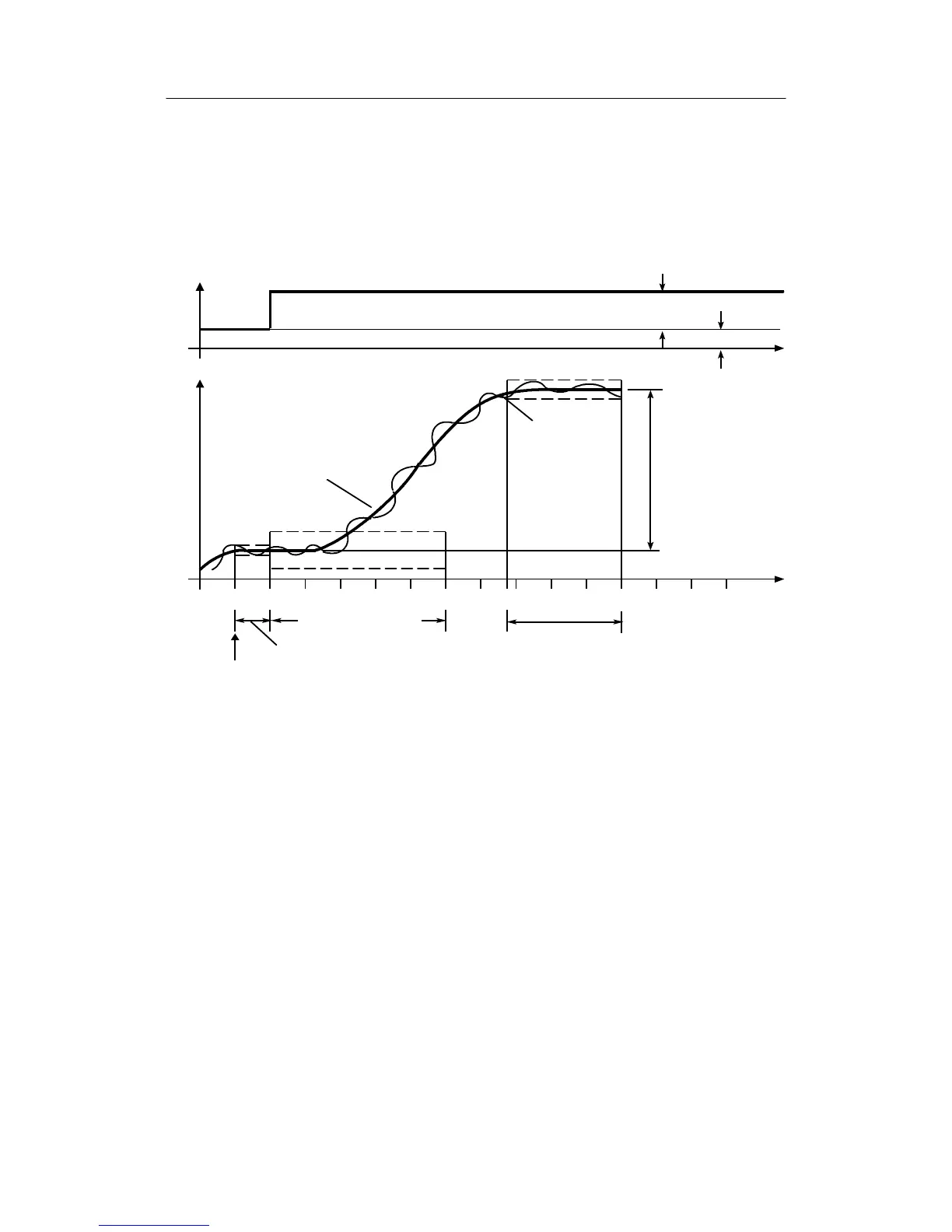

Controlled systems with compensation and periodic transients of 1st and 8th order with a

transient time T

95

of 5 s to 12 h can be identified. Dead time parts are permissible. In

S-controllers, the transient time T

95

should be double the actuating time max. (tP/tM).

The monitoring time tU serves to optimize the cancel criteria.

It can always be started with tU = off (dynamic system knowledge is unnecessary).

x

x measuring

process

x

M

Model curve x

M

y

100500-10

F(n,T)=min

tU

y

manual

Δy

Δx=ks⋅Δy

%tU

Full scale

ID

67 %

Start ID

ID fixed state

Start of adaptation

Figure 3-31 Time curve of an adaptation without error messages in which tU = 2× T95

Error checks are made during system identification in order to be able to prematurely abort

the identification. There are 12 control steps altogether which are displayed by flashing on

the digital x- and w-displays when errors occur. As soon as an error message appears, the

system identification is aborted and it must be restarted after correcting the presettings in

the parameterization mode AdAP if necessary. Acknowledgement of error messages, see

chapter 5.4.2, page 155 list of error messages, see table 5-3page 162.

D Controller design

The controller is designed according to the absolute value optimum method (S48=2). This

setting method is very robust and also allows variation of the line amplification. However, it

generates an overshoot of approx. 5 % in the event of changes in the command variables. If

this is undesirable, operation can also take place with the controller design without overshoot

(S48 = 1). Kp is reduced to 80% here.

Loading...

Loading...