1HL1Manual

SIPART DR21

C73000-B7476-C143-08

9

1 General Part -- Fundamental control technology terms

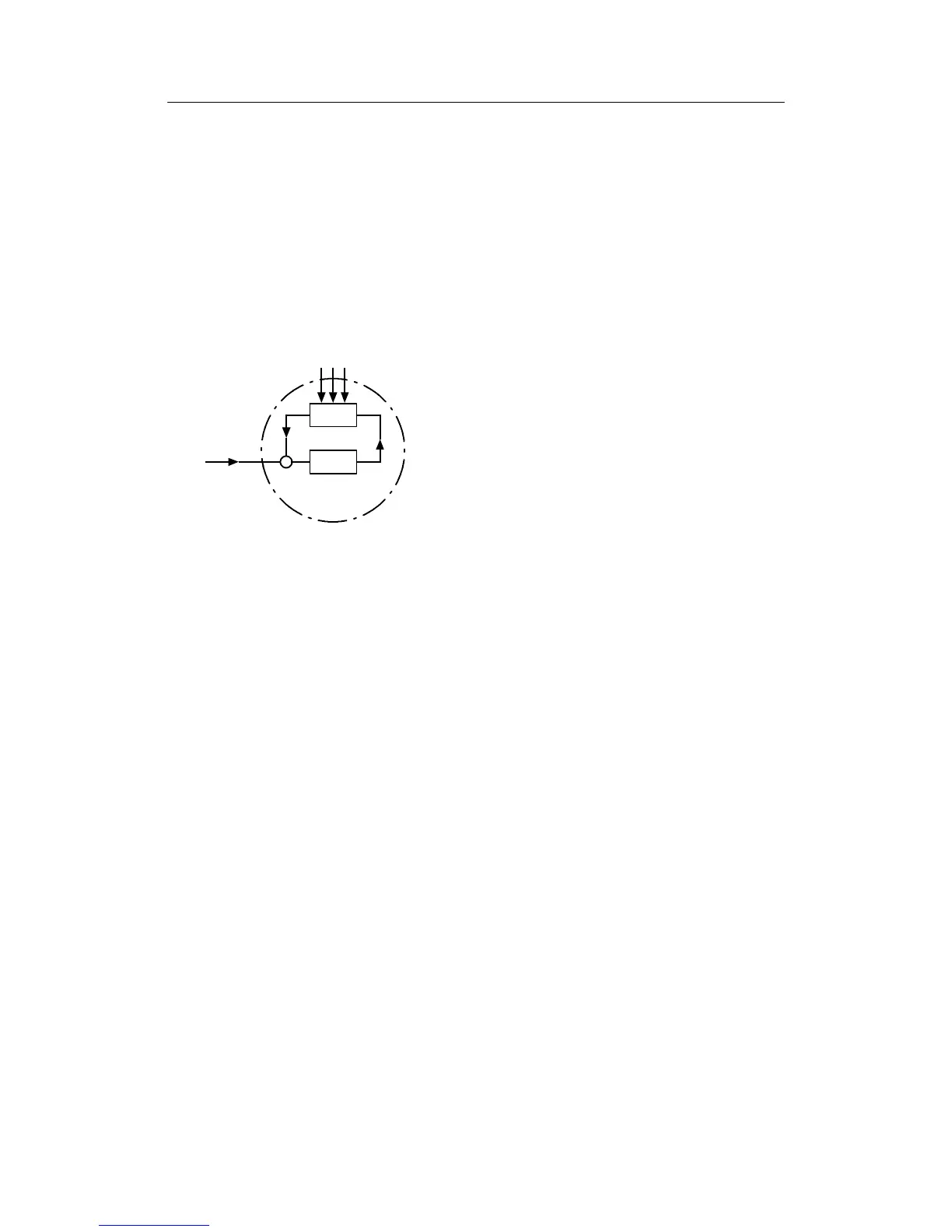

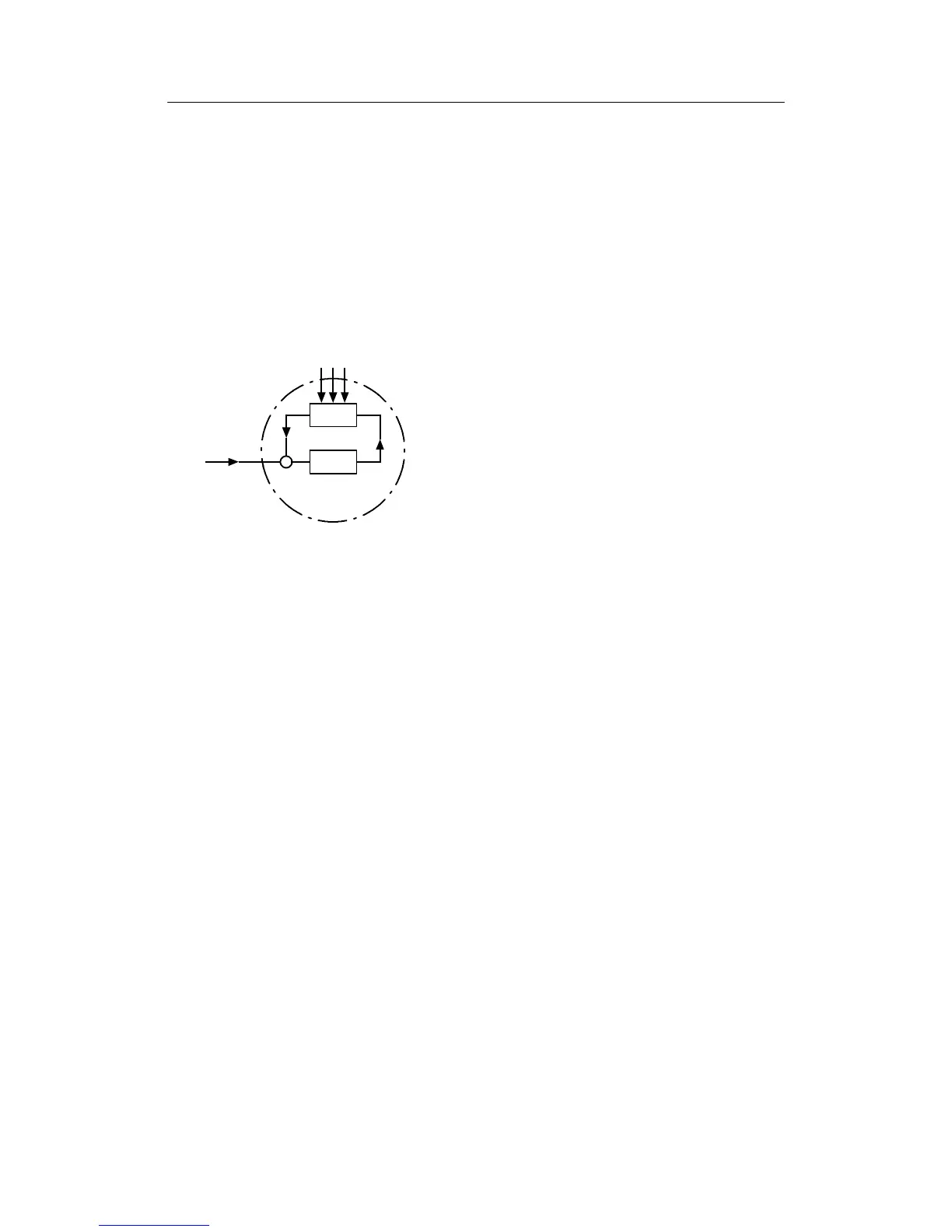

D Control loop

The function of a closed-loop control is to bring the output variable x of a controlled system

to a predefined value and to retain this value even under the influence of disturbance

variables z. The controlled variable x is compared with the command variable w. The

resulting system deviation xd = w -- x is processed in the controller to the manipulated

variable y which acts on the controlled system.

The controlled variable x is measured cyclically in a digital control.

w Command variable

x Controlled variable

xd System deviation

y Manipulated variable

z Disturbance variable

1 Controlled system

2 Control equipment

z1 z2 z3

1

2

y

x

xd

w

-

+

Figure 1-1 Function diagram of control loop

D Sensors and transmitters

The controlled variable can be any physical variable. Frequently controlled variables in pro-

cess engineering are pressure, temperature, level and flow.

In most process engineering applications, the process variables are measured using sensors

and transmitters with a standardized signal output (0 to 20 mA or 4 to 20 mA). The standard-

ized signal can be connected to several process process devices (loop between e.g. re-

corder/indicator/controller). Temperature sensors such as resistance thermometers or ther-

mocouples, as well as resistance transmitters, can be connected directly to the controller

using appropriate input cards (options).

D Final control elements and actuators

In process engineering applications, the manipulated variale y primarily acts on the con-

trolled system via a valve, a butterfly valve or another mechanical means of adjustment.

Three types of drive are possible for actuating such final control elements:

- Pneumatic actuators with compressed air as the auxiliary energy and electropneumatic

signal converters or electropneumatic positioners. These have a proportional action and

are driven by continuous controllers.

- Electric actuators, consisting of an electric motor and gear unit. These have an integral

action and are driven by three-position step controllers. Electric actuators are also poss-

ible with an integrated (series-connected) positioner and then have a proportional action

and can be driven by continuous controllers.

Loading...

Loading...