Line Modules Booksize

4.6 Active Line Modules Liquid Cooled

Booksize Power Units

216 Manual, (GH2), 07/2016, 6SL3097-4AC00-0BP8

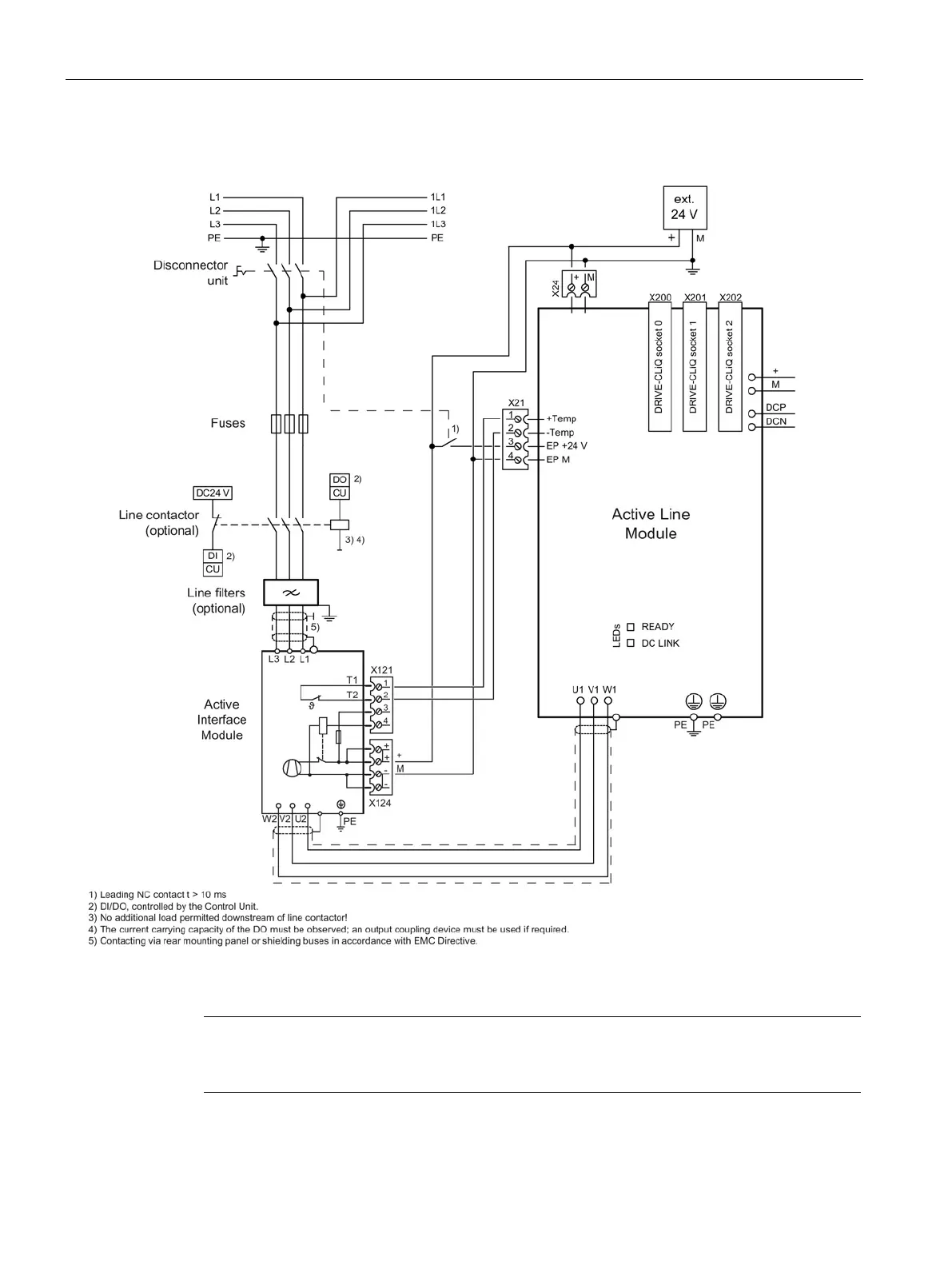

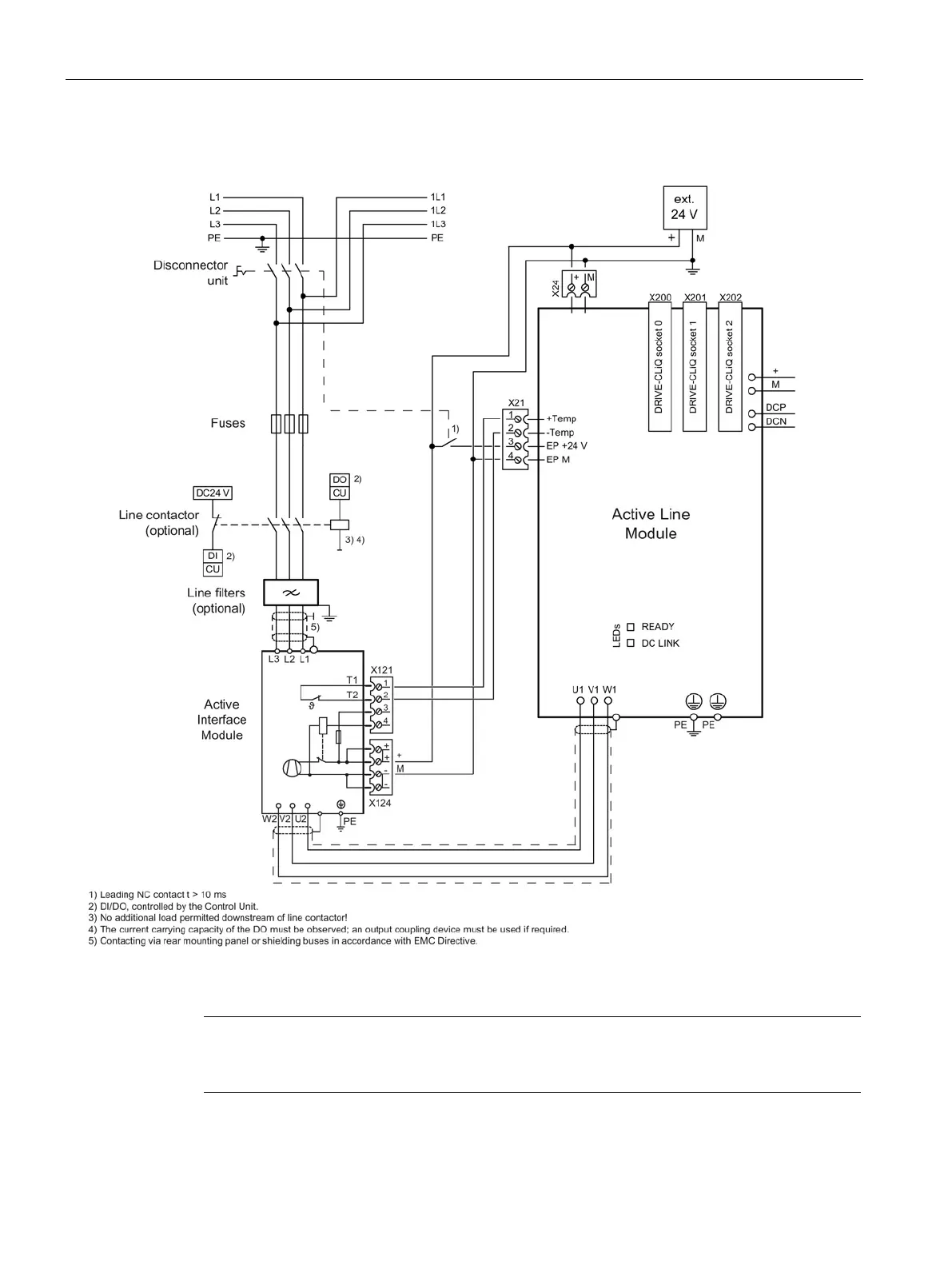

Figure 4-35 Example connection of Active Line Module

a VSM10 Voltage Sensing Module, the leading opening contact can be

Loading...

Loading...