© Jun 2022 5-6 TB24 Plus&26J Plus Maintenance Manual

MAINTENANCE PROCEDURES

• Return the manual to the storage container after

each use.

Note: If the manuals need to be replaced, please

contact Hunan Sinoboom Intelligent Equipment Co.,

Ltd..

A-2 Inspect All Decals

Ensuring all decals in good condition is vital to safe

machine operation. Decals serve not only to alert the

operator to potential hazards but also to provide the

user with information regarding operation and

maintenance. An illegible decal will fail to provide

correct instructions for the operator, which may lead to

the occurrence of unsafe operation.

• Refer to the Decals/Nameplate Inspection in

Operation Manual and use the list and chart of

decals to determine the correct location of a decal.

• Verify all decals are legible and free of damage, and

replace in time if necessary.

Note: If the decals on the machine need to be replaced,

please contact Hunan Sinoboom Intelligent Equipment

Co., Ltd..

A-3 Inspect Damaged, Loose or Lost

Parts

Before each use or work shift,check the machine for

any damaged, improperly installed, loose or lost parts

and unauthorized changes:

• Electrical components, wiring,cables and safety

rope

• Hydraulic hoses & fittings, hydraulic cylinder and

manifolds

• Fuel tank and hydraulic tank

• Storage battery pack and its connection

• Drive motor & reducer, slewing motor & reducer

• Boom wear pads and telescopic axle wear pads

• Limit switch and horn

• Tires and rims

• Engine and associated parts

• Alarms and lighting (if equipped)

• Platform(including rails, floor plate, safety lock,

brackets and entry door)

• Personal protection equipment

• Emergency control equipment

• Operation instructions, warning and control decals

• Structure and welding cracks

• Nuts, bolts and other fasteners

NOTICE

If damaged parts, incorrect installation or missing

parts are discovered, please replace immediately

and install correctly; if the fasteners are found

detached or loose, please secure immediately.

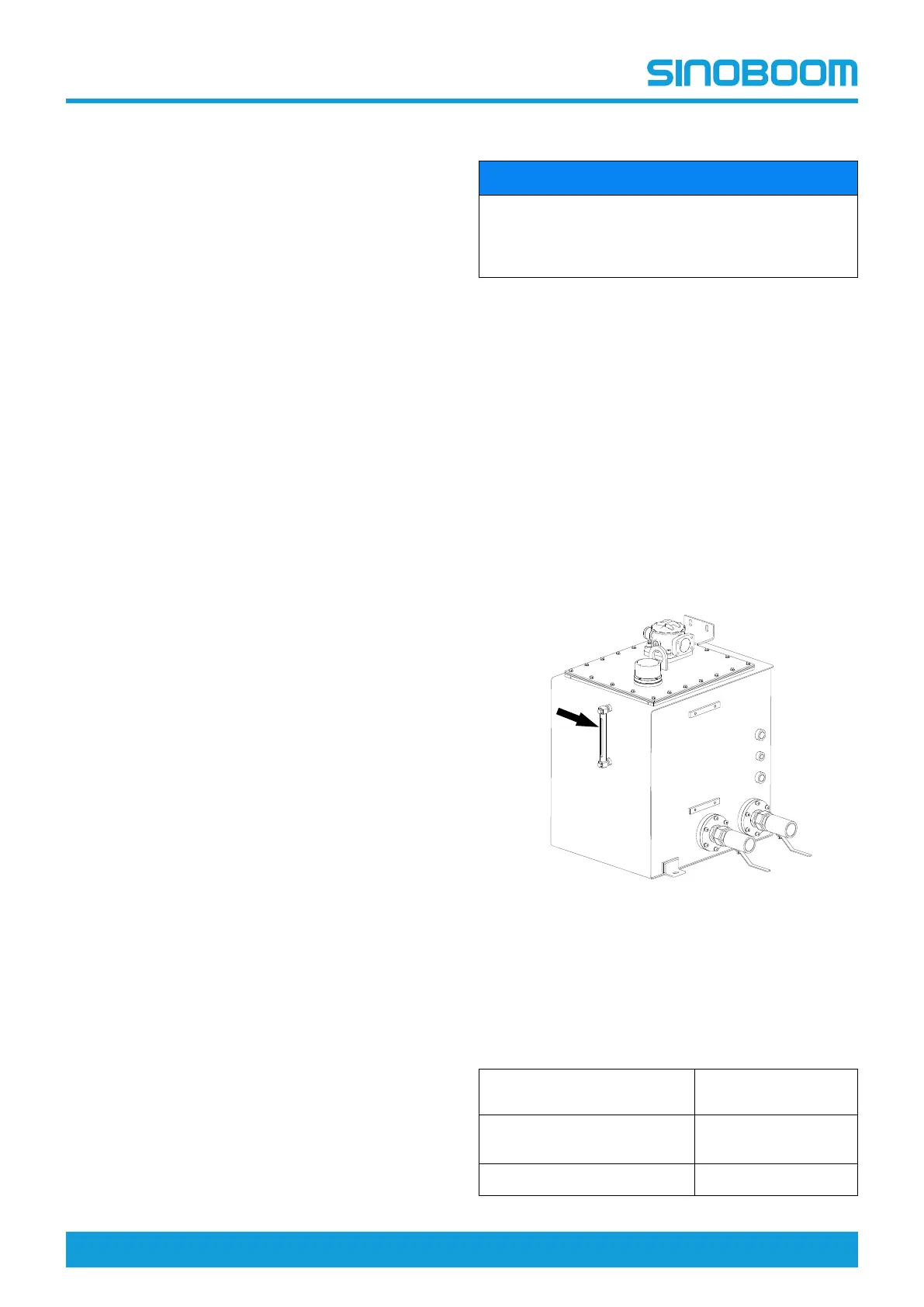

A-4 Inspect Hydraulic Oil Level

Ensuring appropriate hydraulic oil level is vital to proper

operation of the machine. If too high, the oil will spill out

from the oil tank during machine operation, if too low,

the oil pump will suction air and damage hydraulic

components. Performing daily inspection of the

hydraulic oil level will help you determine if a problem

exists in the hydraulic system.

Perform the following procedures with the boom in

stowed position:

1. Open the left turntable cover to make visual

inspection of the sides of hydraulic tank, the

hydraulic oil level should be within the marking

range of oil level indicator.

Figure 5-1

2. Ensure the hydraulic tank body and its connections

are free of leaks.

3. Add oil as needed. Never overfill the tank.

Table 5-4

CUSTOMER

REQUIREMENTS

HYDRAULIC OIL

MARK

Normal-temperature region

0°C to 40°C (32°F to 104°F)

L-HM46

Cold region

L-HV32

Loading...

Loading...